Low-noise industrial scavenger fan

A ventilation fan and low-noise technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of large air ineffective flow, little improvement of defects, and insignificant effects And other problems, to achieve the effect of improving efficiency, reducing energy loss, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

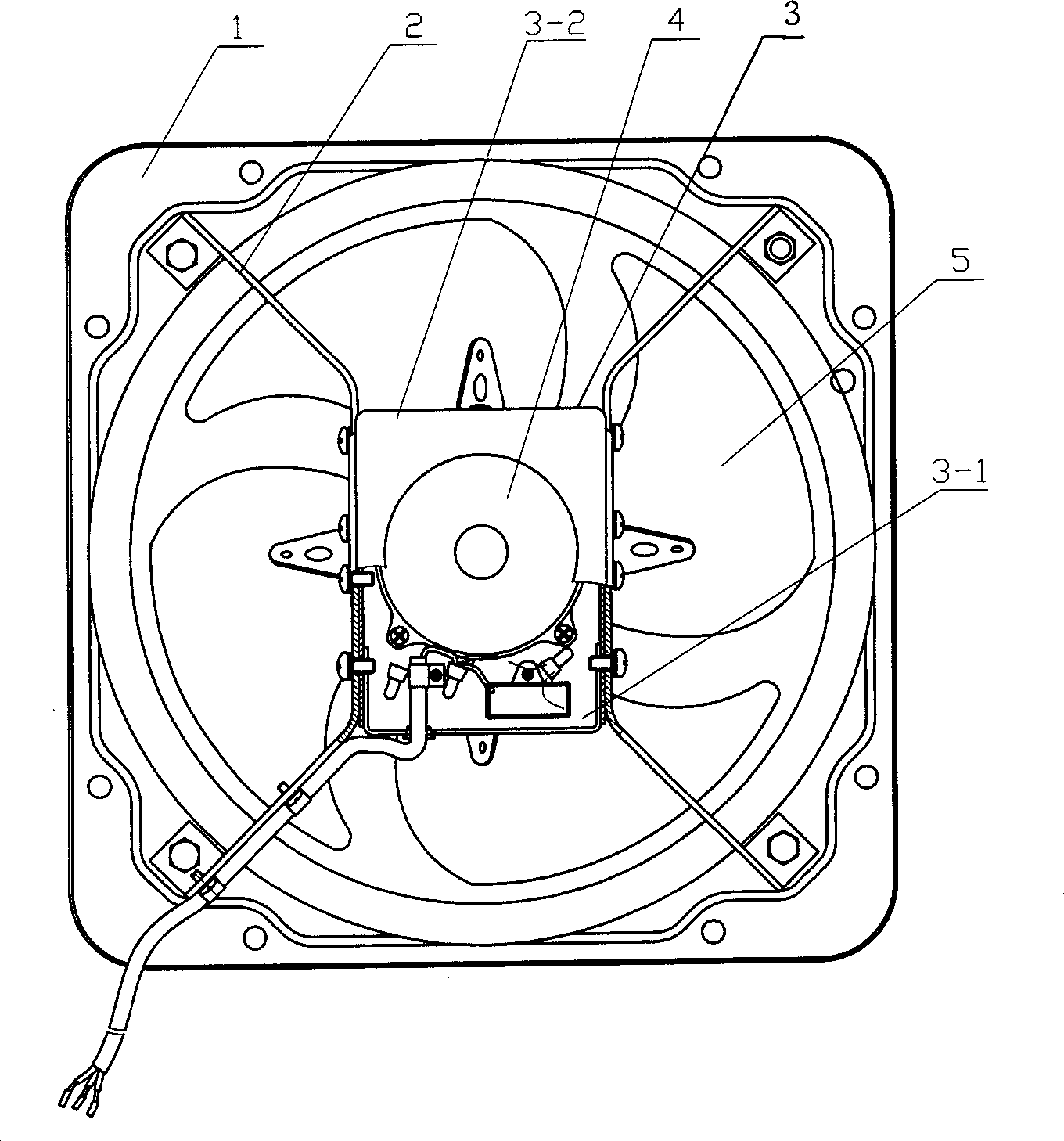

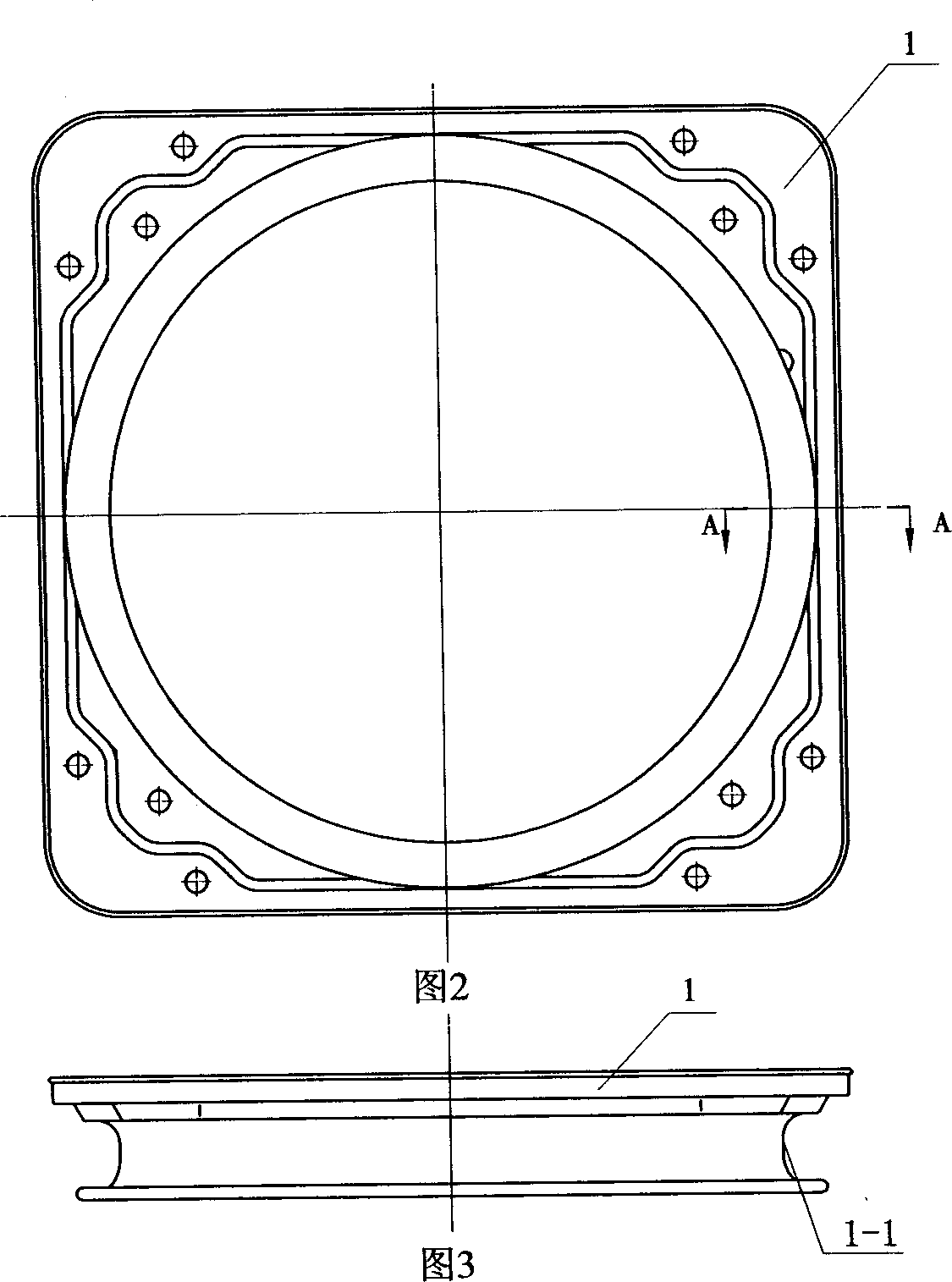

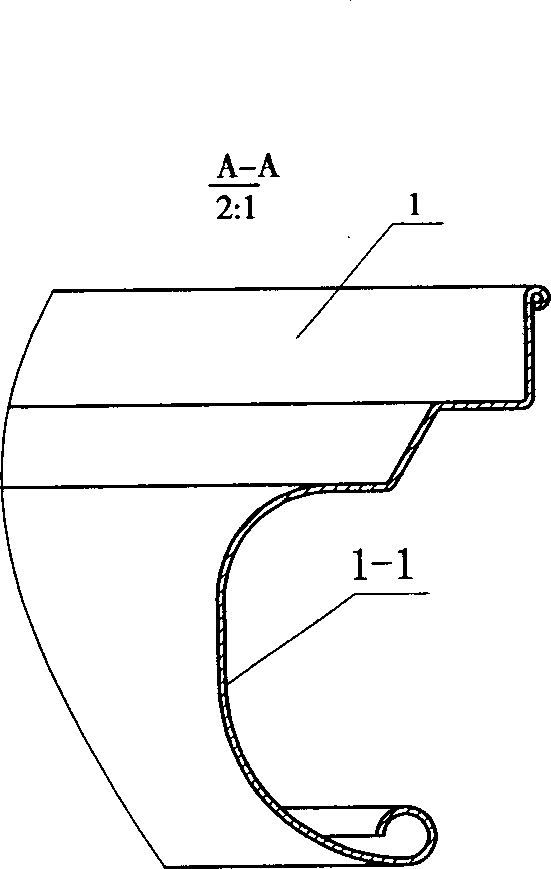

[0032] An industrial ventilation fan is composed of panel 1, bracket 2, motor box 3, motor 4 and impeller 5. Wherein, the motor 4 device is inside the bottom box 3-1 of the motor box 3, cover the box cover 3-2, the support 2 has 4 support rods, one end of the rod is connected or welded on the motor box 3 with a fastener, and the other One end is also connected or welded on the panel 1 with a fastener; the impeller 5 includes a blade 5-1, a blade frame 5-2 and a shaft sleeve 5-3, such as Figure 12 As shown, there are four blades 5-1, which are respectively fixed on the blade frame 5-2 with fasteners, rivets or welding, and the center of the blade frame 5-2 is fixedly provided with a shaft sleeve 5-3, and the shaft sleeve 5- 3 is tightly sleeved on the transmission shaft that motor 4 stretches out.

[0033] Such as Figure 5 , Image 6 , Figure 9, Figure 10As shown, the arrangement of each blade 5-1 on the 4-blade impeller adopts twisted type, forward-inclined type, and va...

Embodiment 2

[0043] With embodiment 1, only, impeller adopts 5 impellers. Such as Figure 11 Shown, make the integral plastic impeller 5 that 5 blades 5-1 of engineering plastics are connected with the disk of blade holder 5-2, and axle sleeve 5-3 is arranged on the disc center of blade holder 5-2. Blade 5-1 also adopts twisted and forward-leaning designs. The relevant parameters are listed in the table below. All the other are with embodiment 1.

[0044] parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com