Numerical control method

A technology for controlling axes and time functions, applied in the field of numerical control, can solve the problems of position deviation, large error between commands, uneven acceleration integral feed, etc., and achieve the effect of reducing position deviation and reducing uneven feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

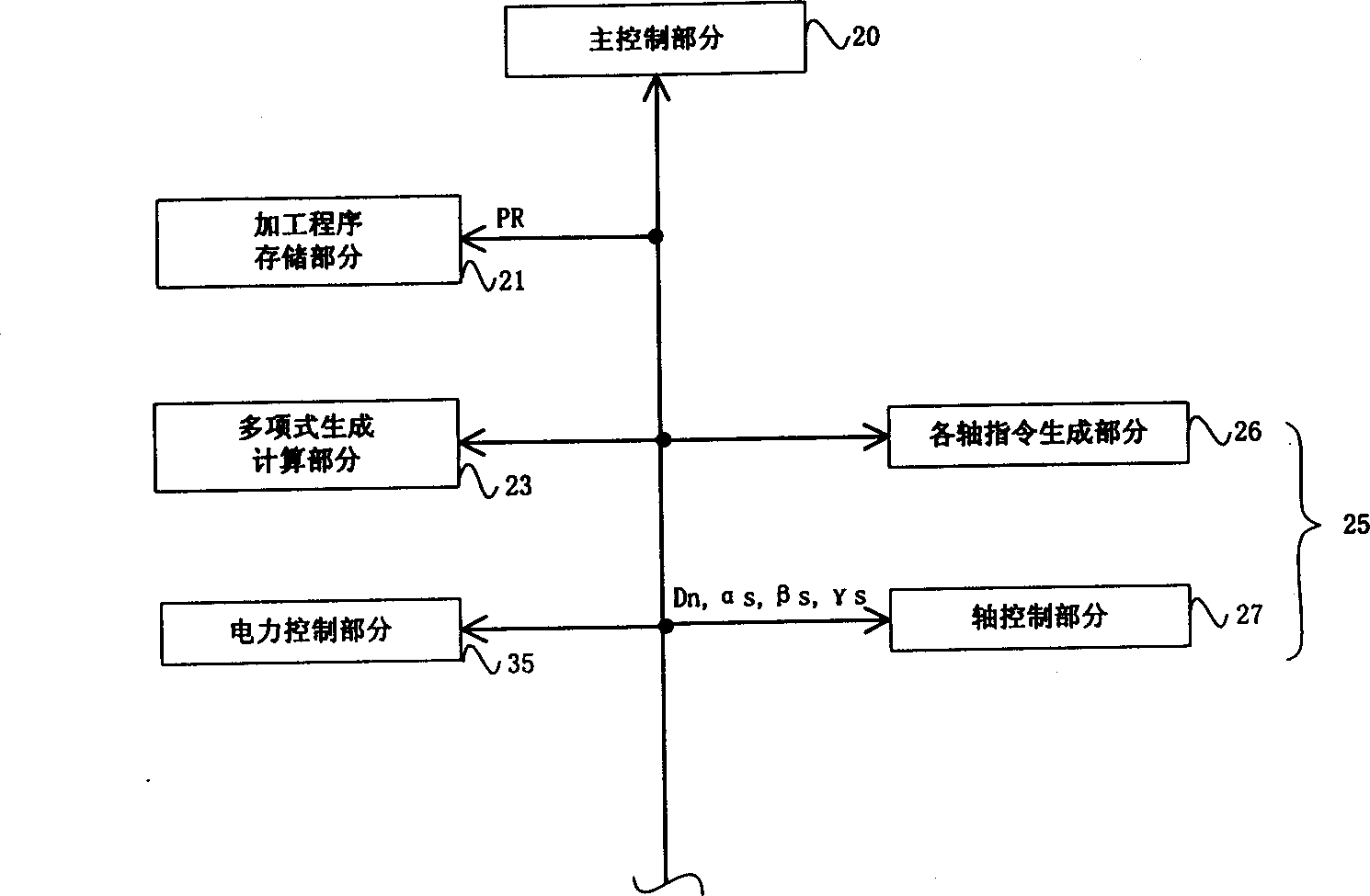

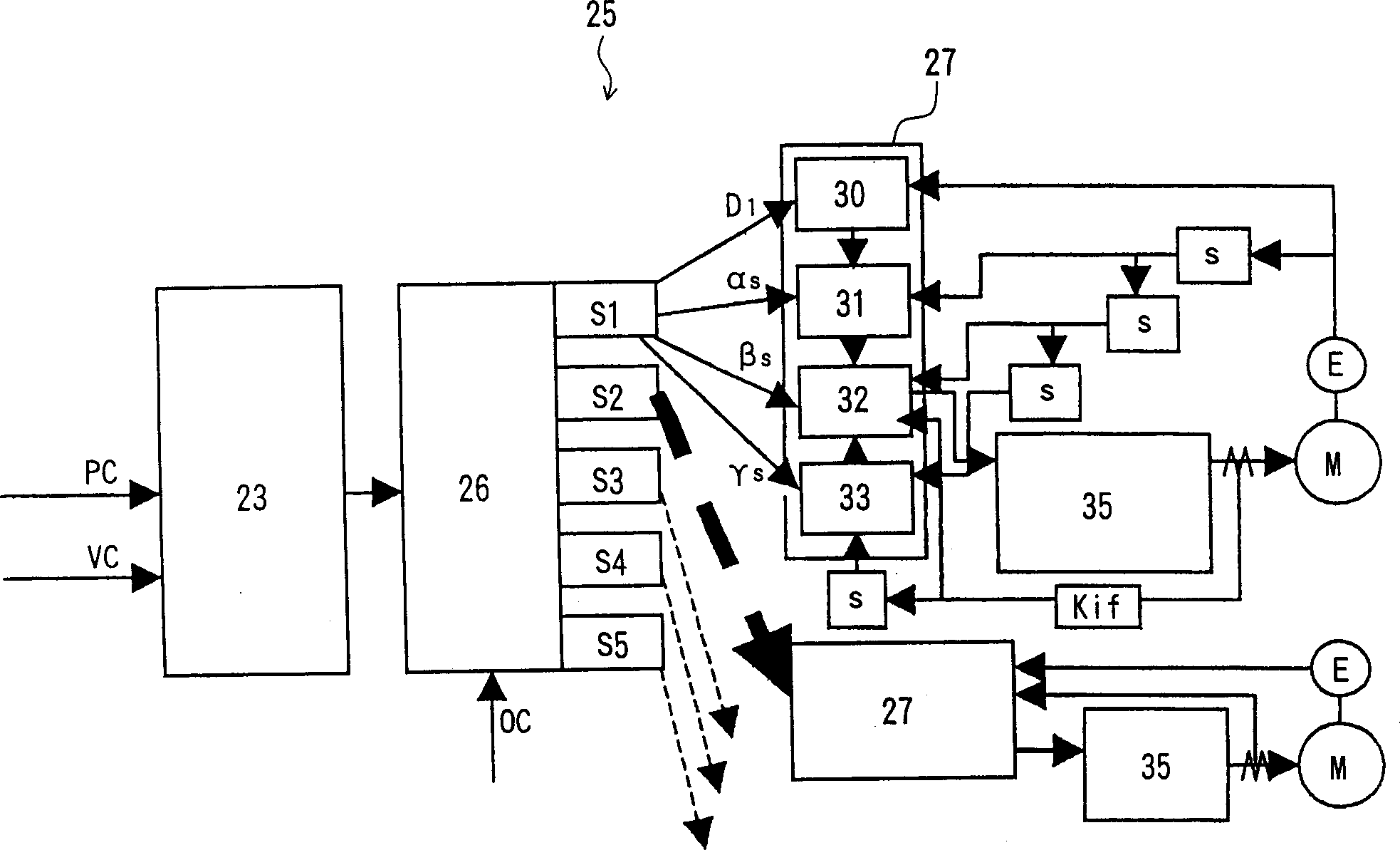

[0028] specific implementation plan

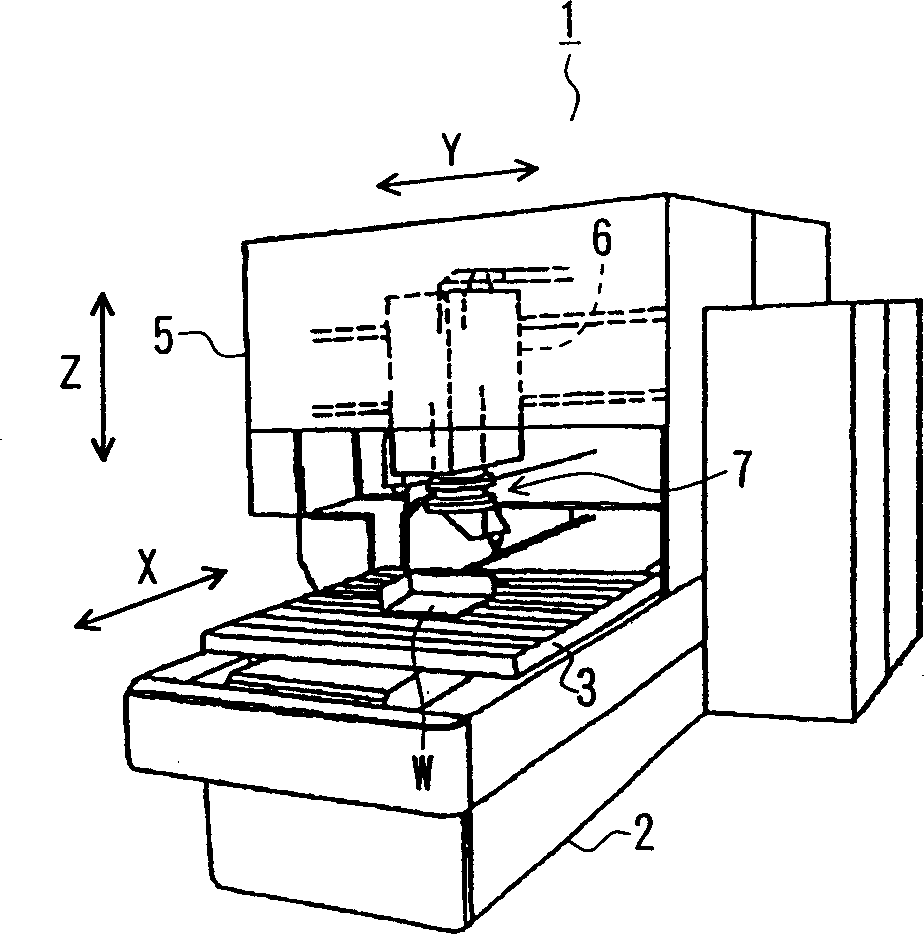

[0029] Fig. 3 is a diagram showing the appearance of the laser processing machine of the present embodiment. The laser processing machine 1 of this embodiment has a base 2 as shown in FIG. The workpiece W to be processed can be freely set on the table 3 . The base 2 is provided with a pillar 5, which straddles the above-mentioned platform 3, and a saddle 6 is arranged on the pillar 5, and it can be positioned in the horizontal Y-axis direction (the direction orthogonal to the above-mentioned X-axis direction) The drive moves freely.

[0030] A machine head assembly 7 is arranged on the above-mentioned saddle 6, and it can be driven and moved freely in the Z-axis direction as the up-down direction. On the head assembly 7, as shown in Figure 3(b), it is composed of the following parts: the first part 7a is located on the side of the saddle; the second part 7b is arranged to be parallel to the Z axis. 7a is centered on the axis CT1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com