Spindle device of machine tool

A technology for machine tool spindles and spindles, which is used in metal processing machinery parts, large fixed members, maintenance and safety accessories, etc. It can solve problems such as adverse effects on human health, sliding wear of cutting fluid, and inability to supply cutting fluid stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

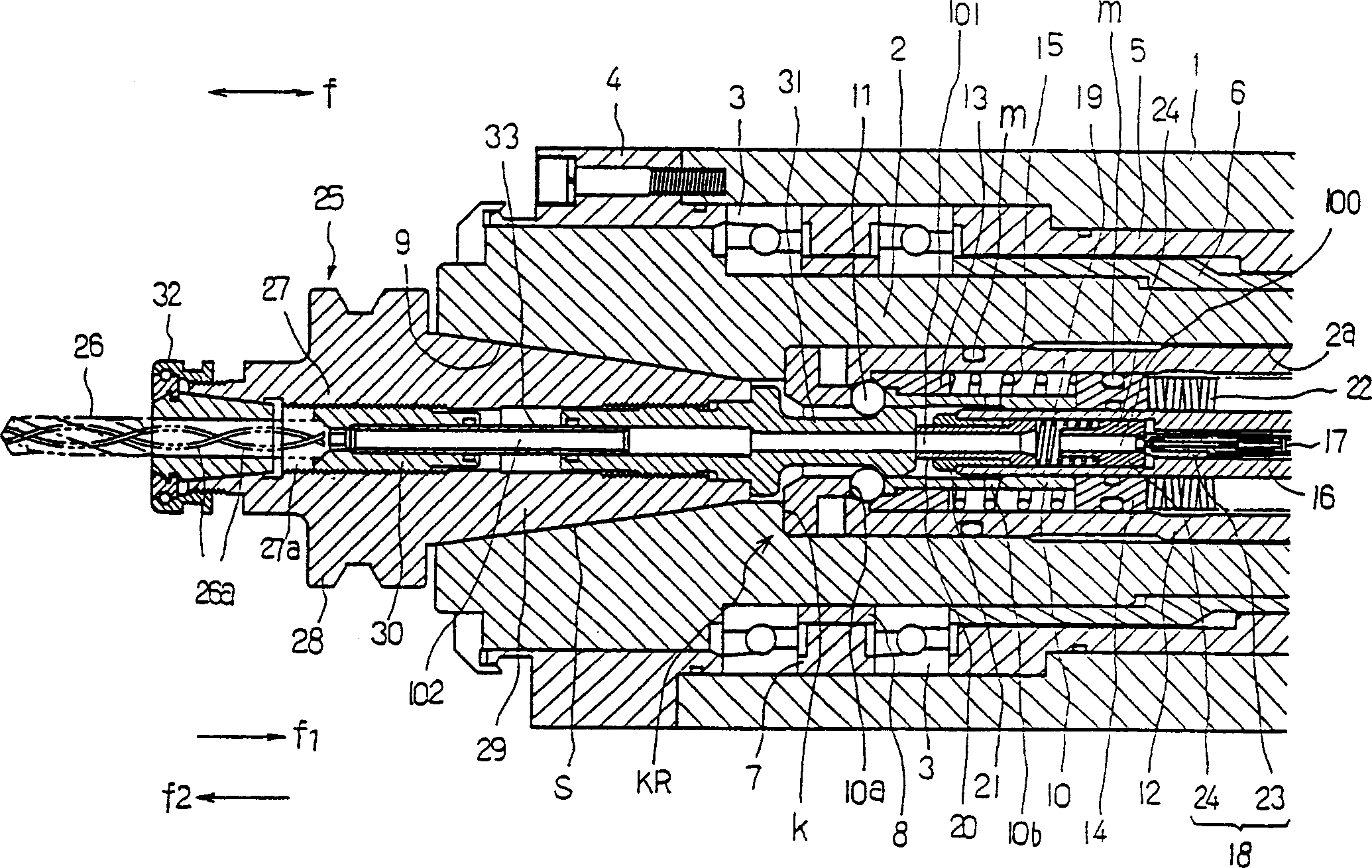

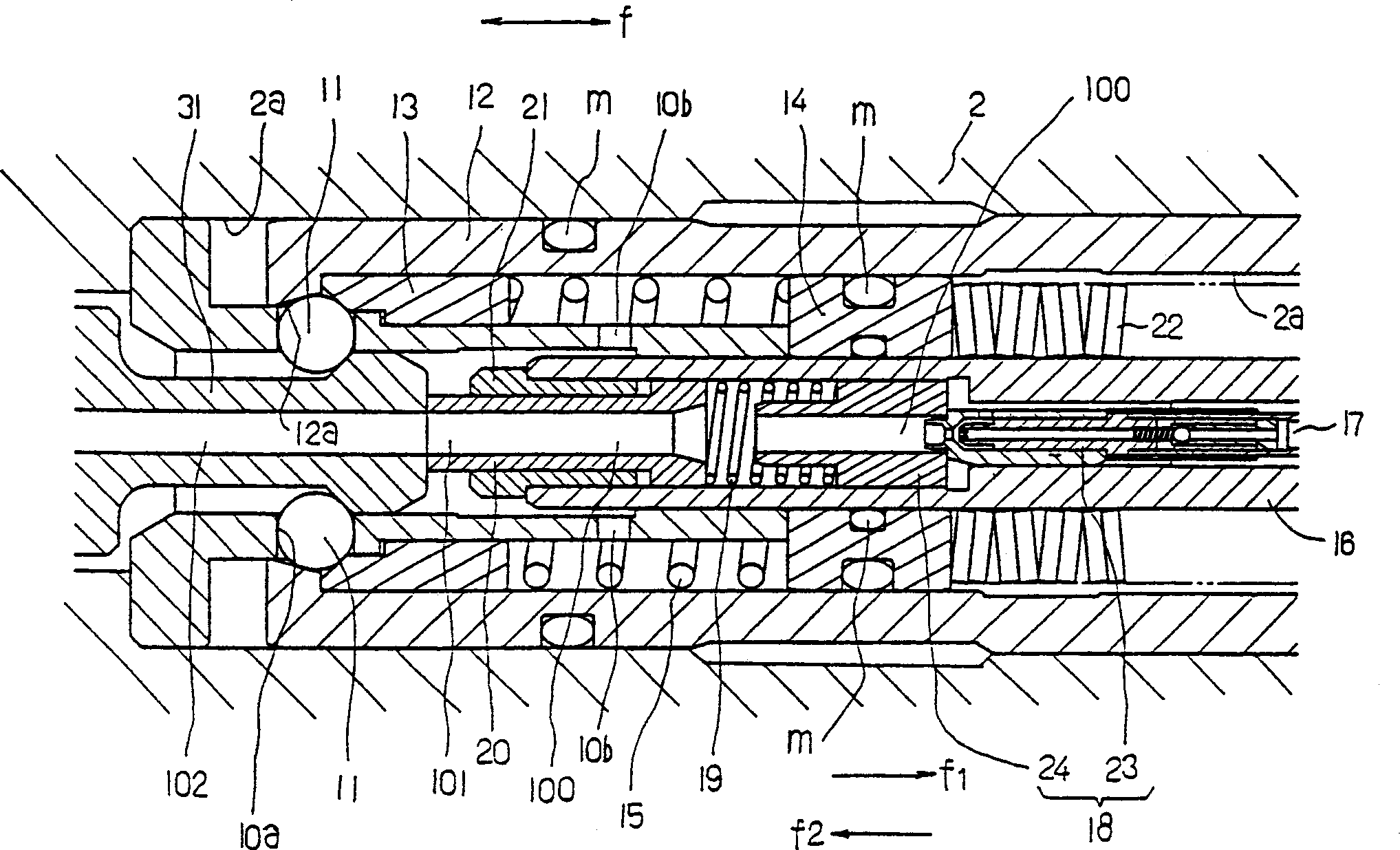

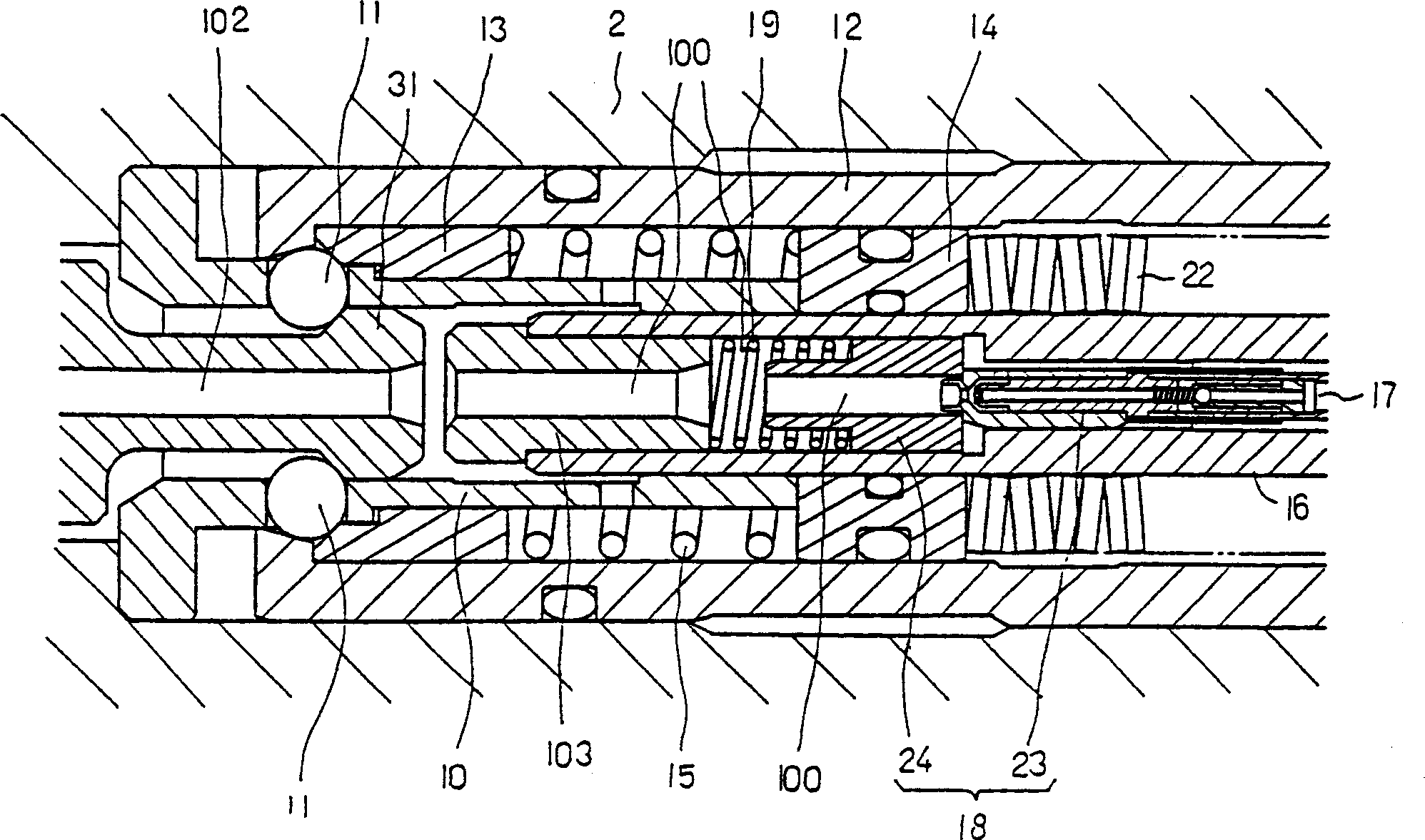

[0021] The present invention will be described below with reference to the accompanying drawings.

[0022] In the accompanying drawings, 1 is a main shaft support of the machine tool, 2 is a main shaft, and the main shaft is rotatably supported by a bearing 3 . 4 is an annular part that limits the displacement of the bearing 3 or the front and rear direction f of the main shaft 2, and is fixed on the front end surface of the main shaft support 1 with bolts. Liners 5, 6, 7, 8 are arranged between the main shaft support 1 and the main shaft 2, and between the bearings 3, 3.

[0023] A locking device KR is formed at the central portion of the above-mentioned main shaft 2 as described below.

[0024] That is, the tip end portion of the inner hole 2 a formed in the center portion of the main shaft 2 serves as the tapered fitting hole 9 . The cartridge 10 is inserted into the back of the inner hole 2a, and its front end is supported by the stepped portion k to be in a fixed state....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com