Forming process of seed crystal bar chuck

A molding method and seed rod technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of rough hole wall, poor finish, poor coaxiality between the inner hole of the chuck and the seed rod, etc. , to achieve the effect of reducing production cost, good coaxiality and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As mentioned above specific molding steps:

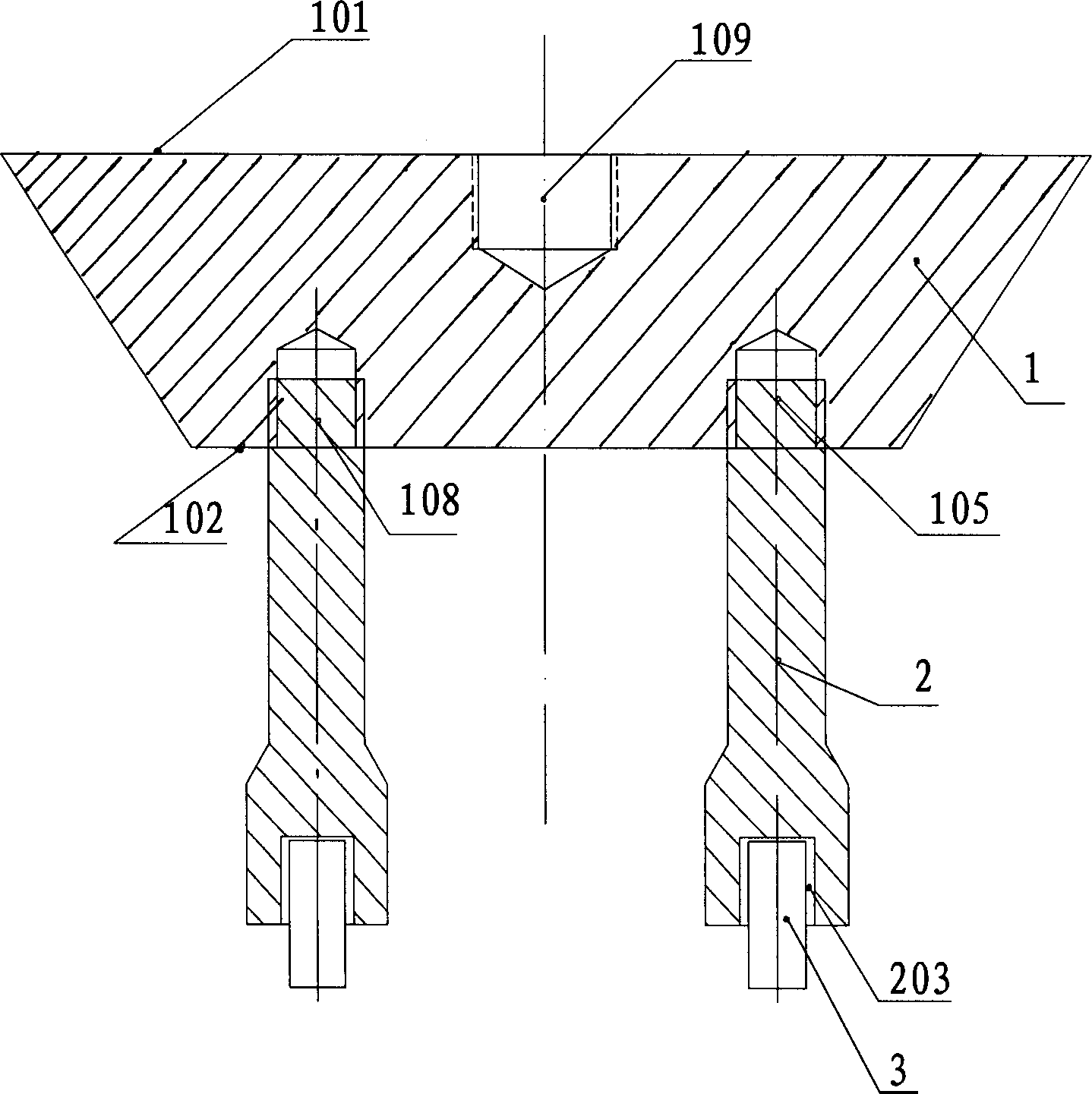

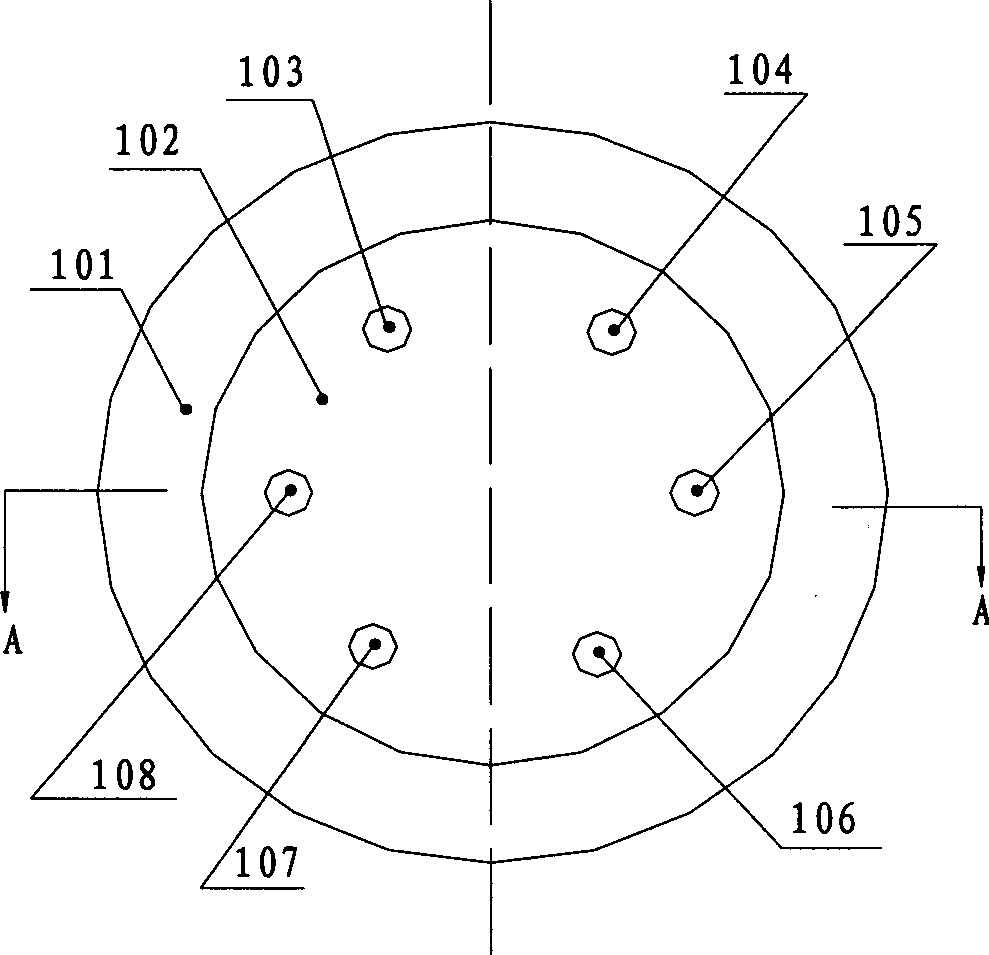

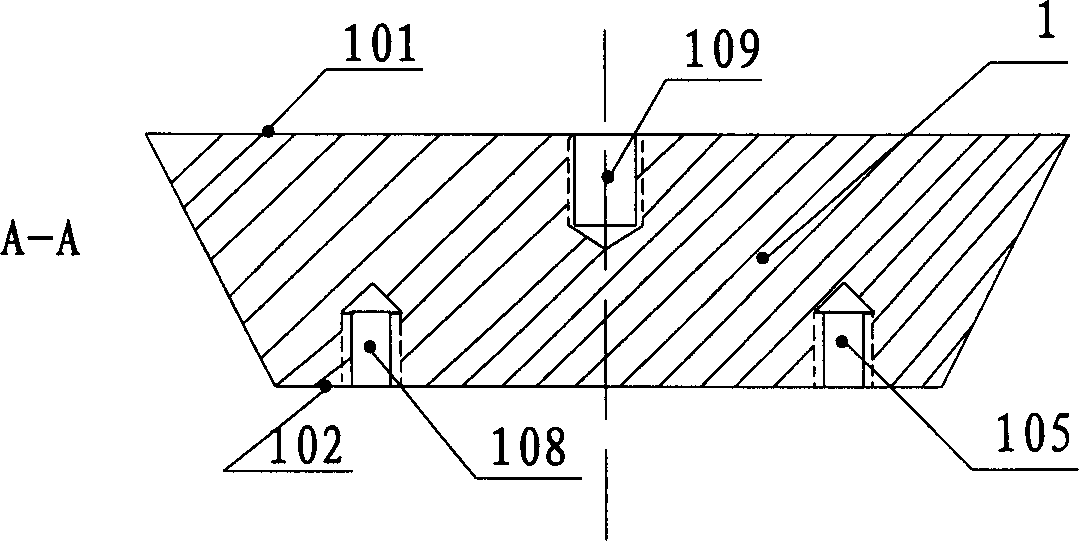

[0020] First make the chuck mold, such as figure 1 The structure shown, the base 1, is processed into a truncated cone shape with high-purity graphite, and there is a fixed center screw hole 109 with a depth of 8mm and M8 at the center of the large circular plane 101, and n=6 fixed molds are evenly distributed on the small circular plane. Core screw holes 103, 104, 105, 106, 107, 108, see figure 2 . There are n=6 chuck die cores 2, the diameter of each chuck die core 2 is 6mm, and the length is 80mm. One end of the chuck die core 2 has a threaded head 201 matching the fixed die core screw hole on the base 1, Such as Figure 4 shown. The other end has a diameter of 5 mm and a depth of 7 mm in the center hole 203, such as Figure 4 shown. First, the base 1 and the clamp core 2 are processed with a lathe using high-purity graphite. Then n=6 collet mold cores are fixed on the base 1 in the fixed mold core screw holes 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com