Vacuum compression preverter of vortex compressor

A scroll compressor and vacuum compression technology, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of thermal damage of the compression mechanism, degradation of compressor performance, and adverse consequences, etc., to achieve Effects of preventing heating and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

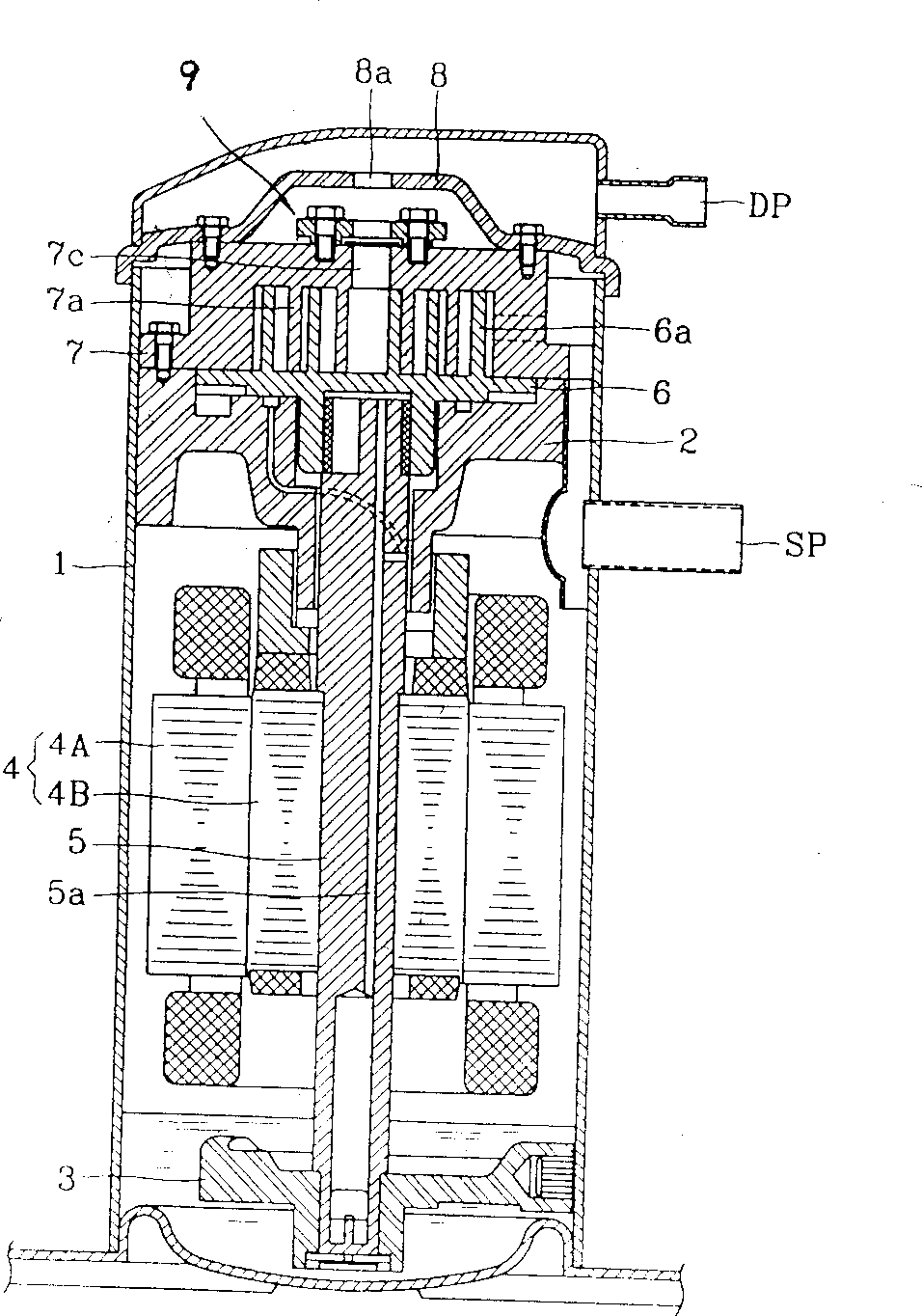

[0026] figure 1 The description in has been described in detail in "Background Technology" and is omitted here.

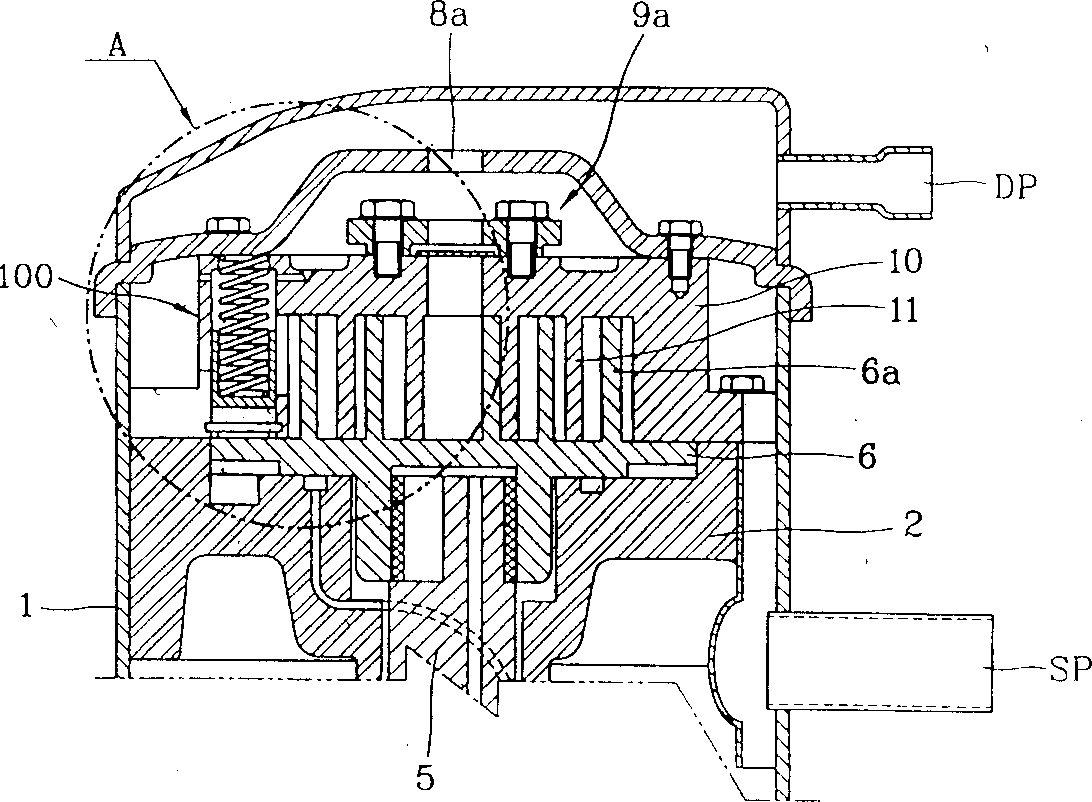

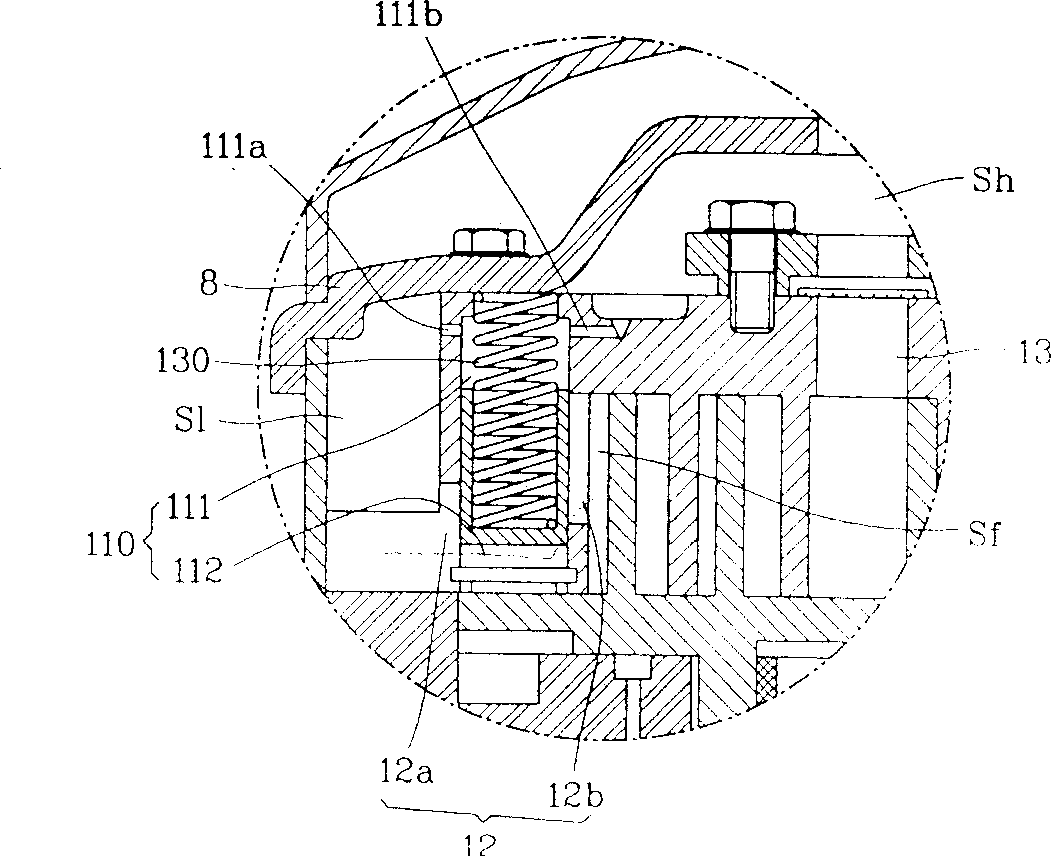

[0027] exist figure 2 , image 3 Among them, the upper bracket (2) is fixed on the casing (1), and the fixed scroll (10) with a high vacuum prevention device (100) is fixed on the convex edge of the upper bracket (2), together with the fixed scroll (10) The movable scroll (6) forming a plurality of compression chambers is connected with the drive shaft (5) of the electric motor as a whole, and the movable scroll (6) is arranged on the upper moving frame (2) and is tightly attached to each other. That is, the movable scroll (6) is embedded in the internal space formed by the fixed scroll (10) and the upper support (2), and rotates with the rotation of the drive shaft.

[0028] On the upper side of the above-mentioned fixed scroll, a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com