Screen printing device and screen printing method

A technology of screen printing and masking plate, which is applied to screen printing machines, printing machines, printing machines, etc., and can solve problems such as unstable printing conditions and quantity fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

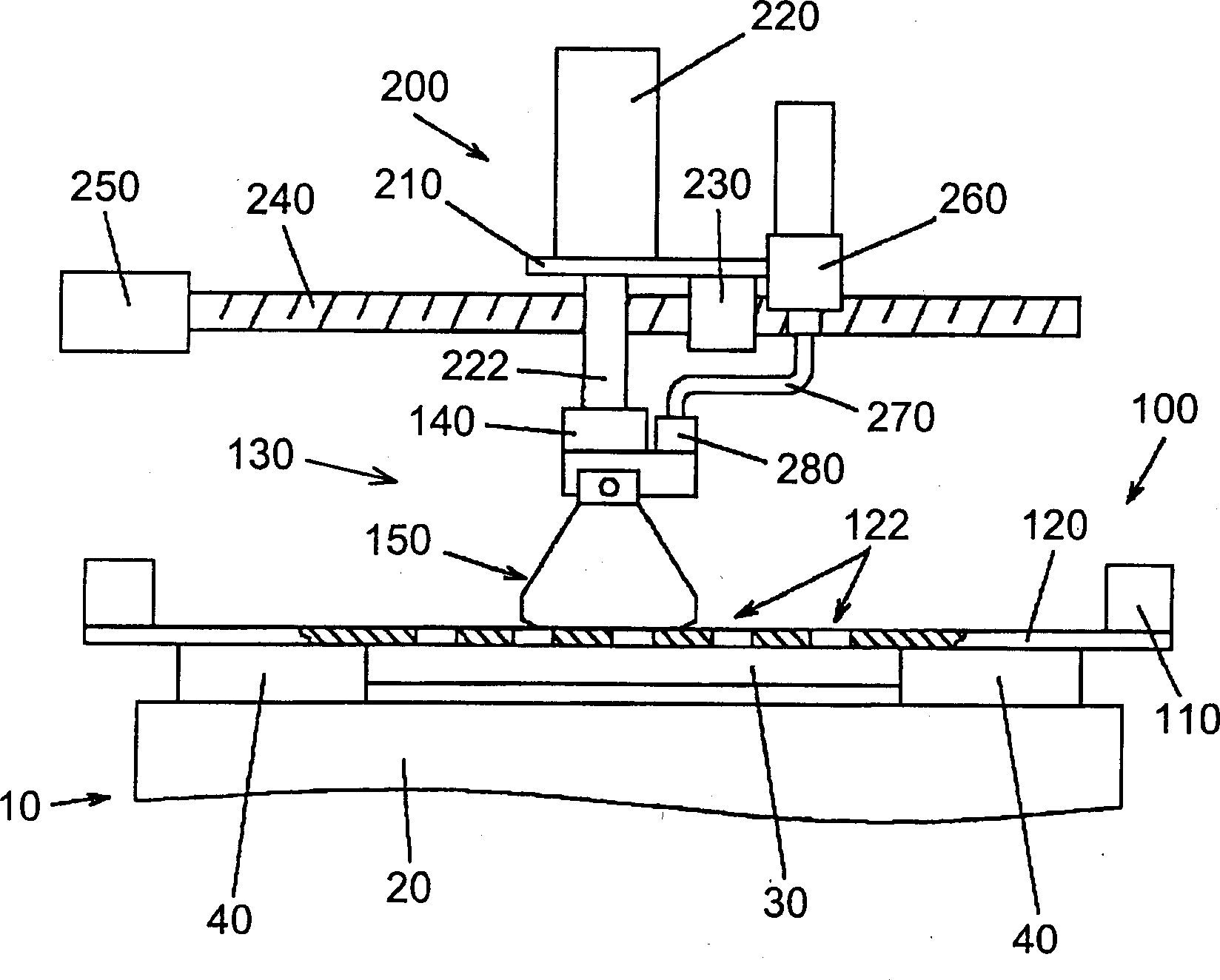

[0020] See figure 1 and 2 , the substrate positioner 10 includes a substrate holder 20 disposed on a movable workbench (not shown in the figure) and a clip 40 connected to the substrate holder 20 . The clamp 40 holds the substrate 30 to be printed, and positions the substrate horizontally and vertically by driving the movable table.

[0021] The screen mask 100 includes a shielding plate 120 attached to the holder 110 and disposed above the substrate positioner 10 . The shielding plate 120 has a plurality of pattern holes 122 corresponding to the positions to be printed on the substrate 30 to form printing patterns on the substrate 30 .

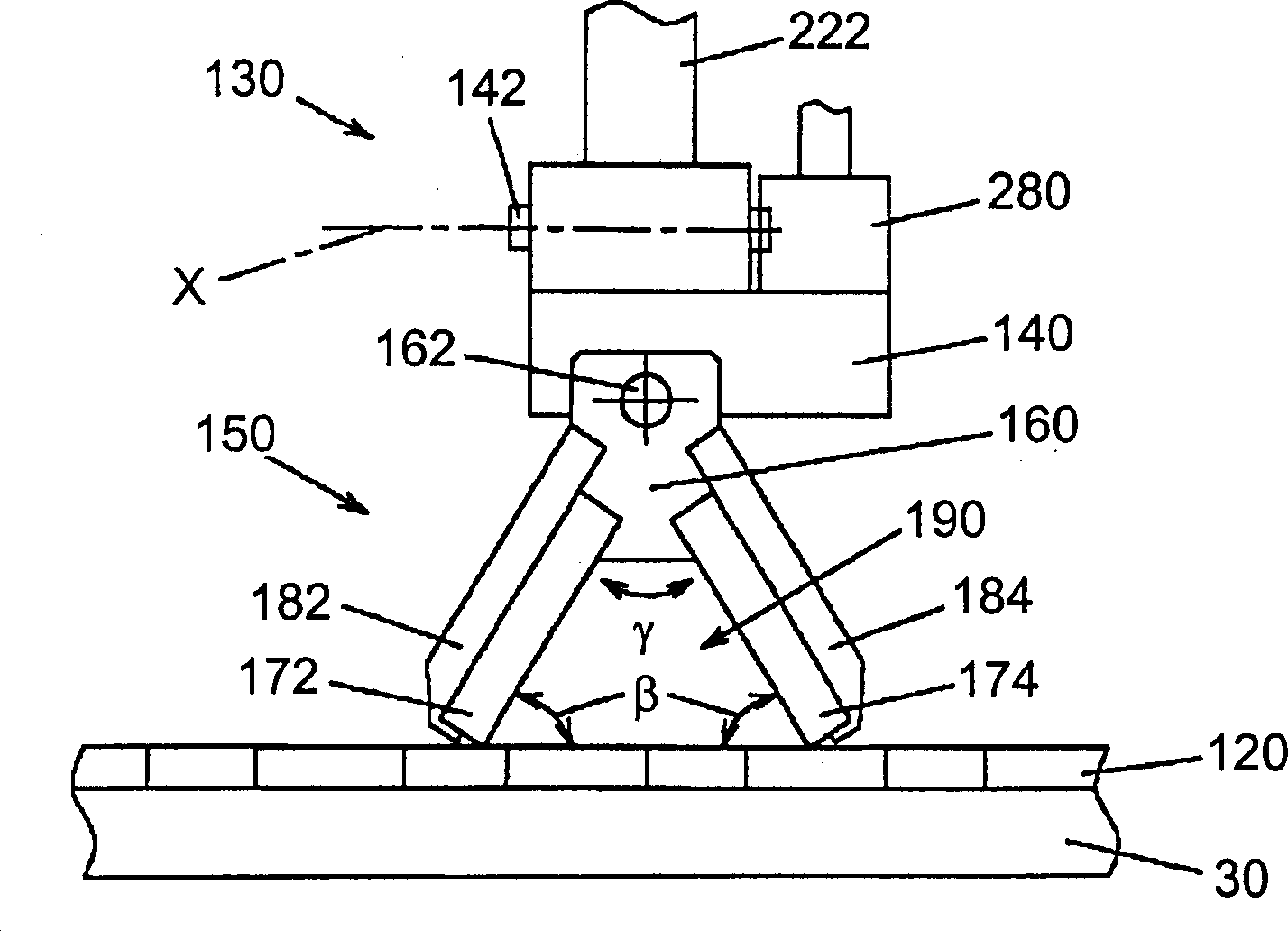

[0022] The squeegee head 130 is located above the screen cover 100 so that the squeegee head 130 can move up and down by means of the head lifter 200 . The head lifter 200 is equipped with a cylinder 220 provided on the plate 210 .

[0023] The squeegee head 130 is connected to the lower end of the rod 222 of the cylinder 220 . The squee...

no. 2 example

[0045] Conventional screen printing devices generally control the temperature of solder by blowing hot air to the solder placed on a shielding plate. According to such a conventional screen printing apparatus, since the solvent in the solder is easily volatilized, there is a disadvantage that the solder hardens in a short time.

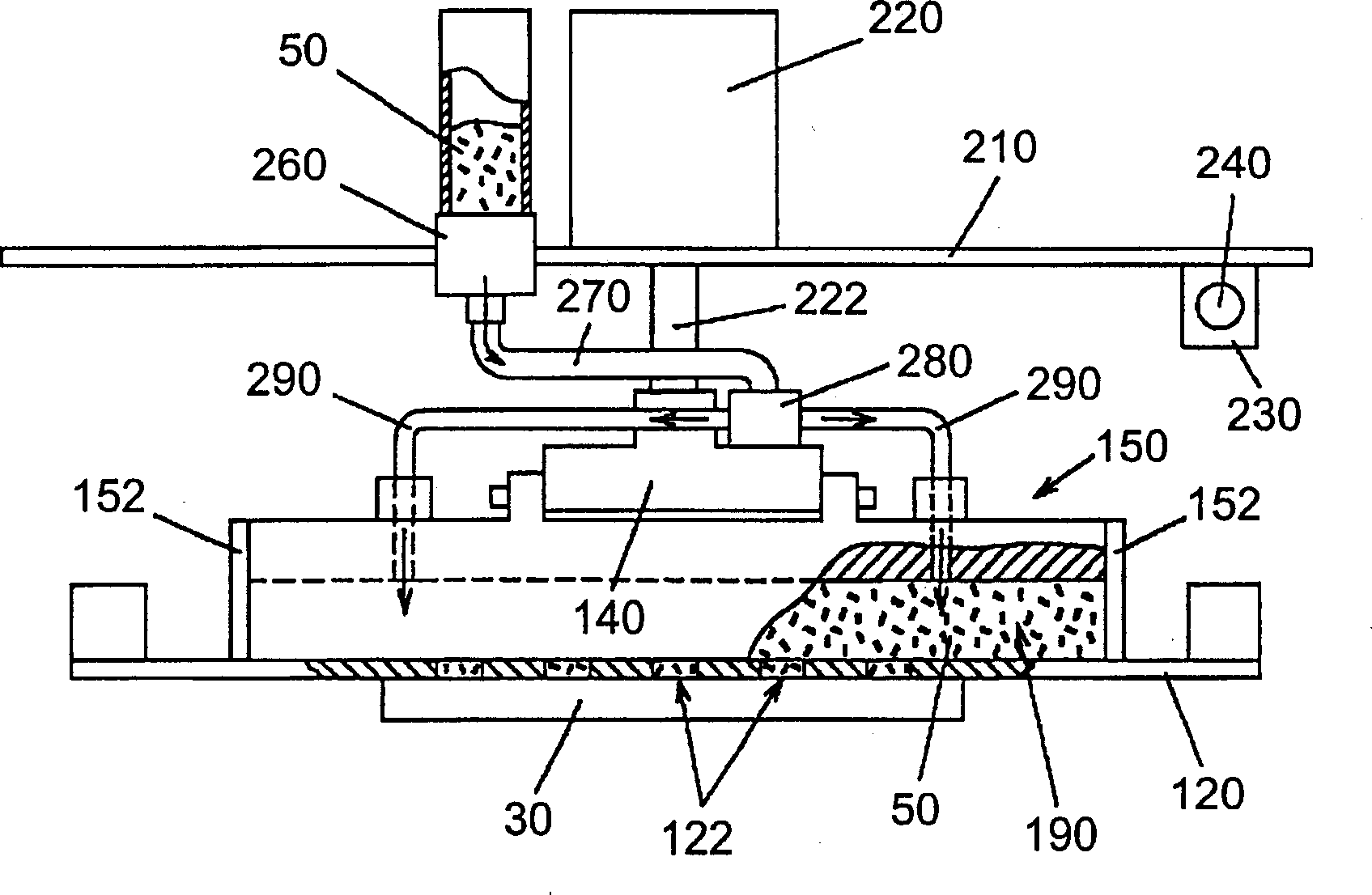

[0046] Such as Figure 6 As shown, the second embodiment is an arrangement of the first embodiment to control the temperature of the solder 50 using a temperature controller in the paste chamber 190 . In the second embodiment, substantially the same components as those of the first embodiment are given the same reference numerals.

[0047] According to the second embodiment, the temperature of a part of the squeegee device 150 is controlled using a temperature controller such as heaters 300 , 302 and 304 provided on the holding plate 182 in order to control the temperature of the solder 50 . In the same way will Figure 6 The same heater not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com