Tableware and method for surface treatment thereof, substrate having hard decorative coating film and method for production thereof, and cutlery

A surface treatment and tableware technology, applied in the field of tableware surface treatment, can solve problems such as unhygienic, lost cutlery and tableware, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

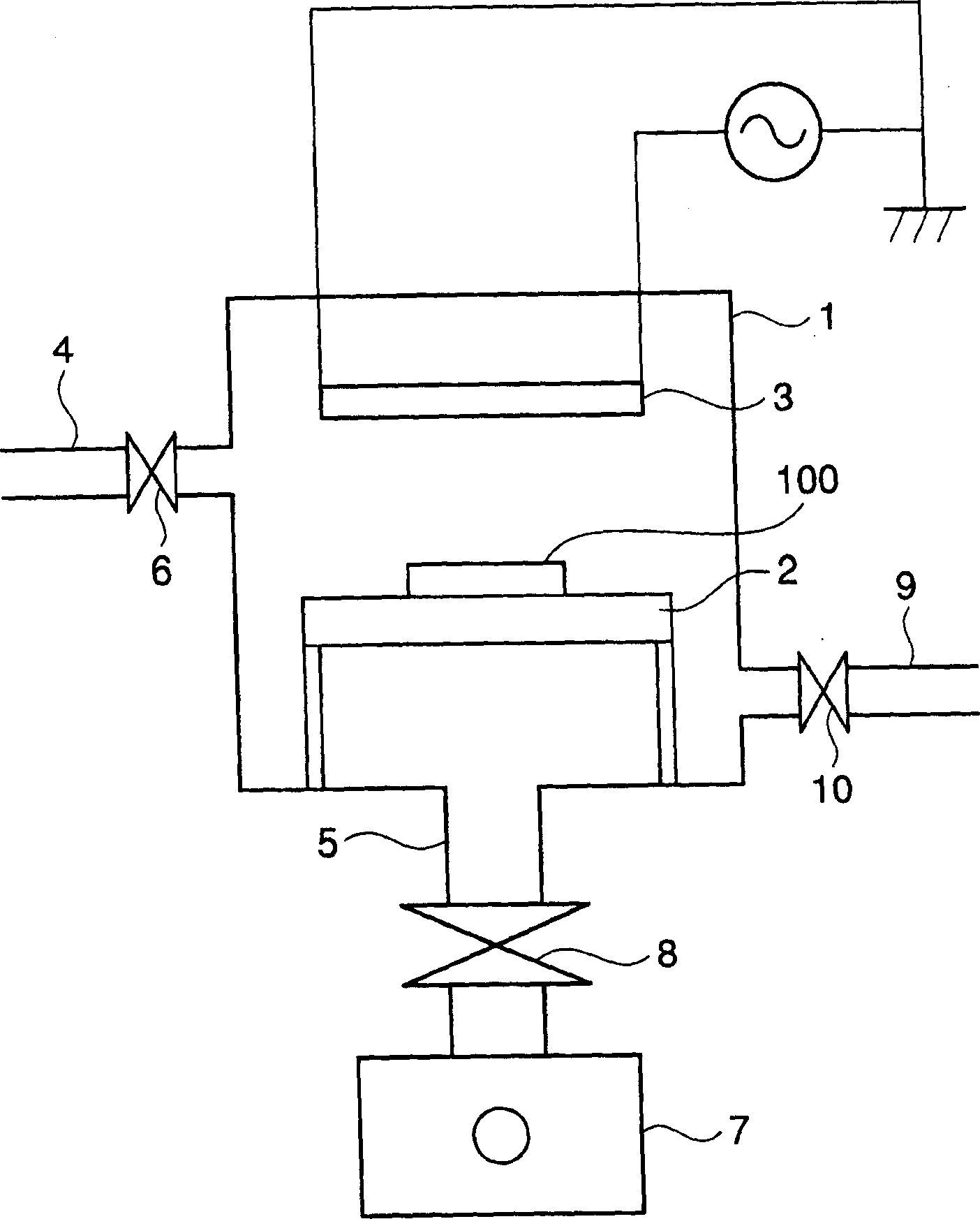

[0153] refer to figure 1 , figure 2 , image 3 with Figure 4 A first embodiment of the present invention is described.

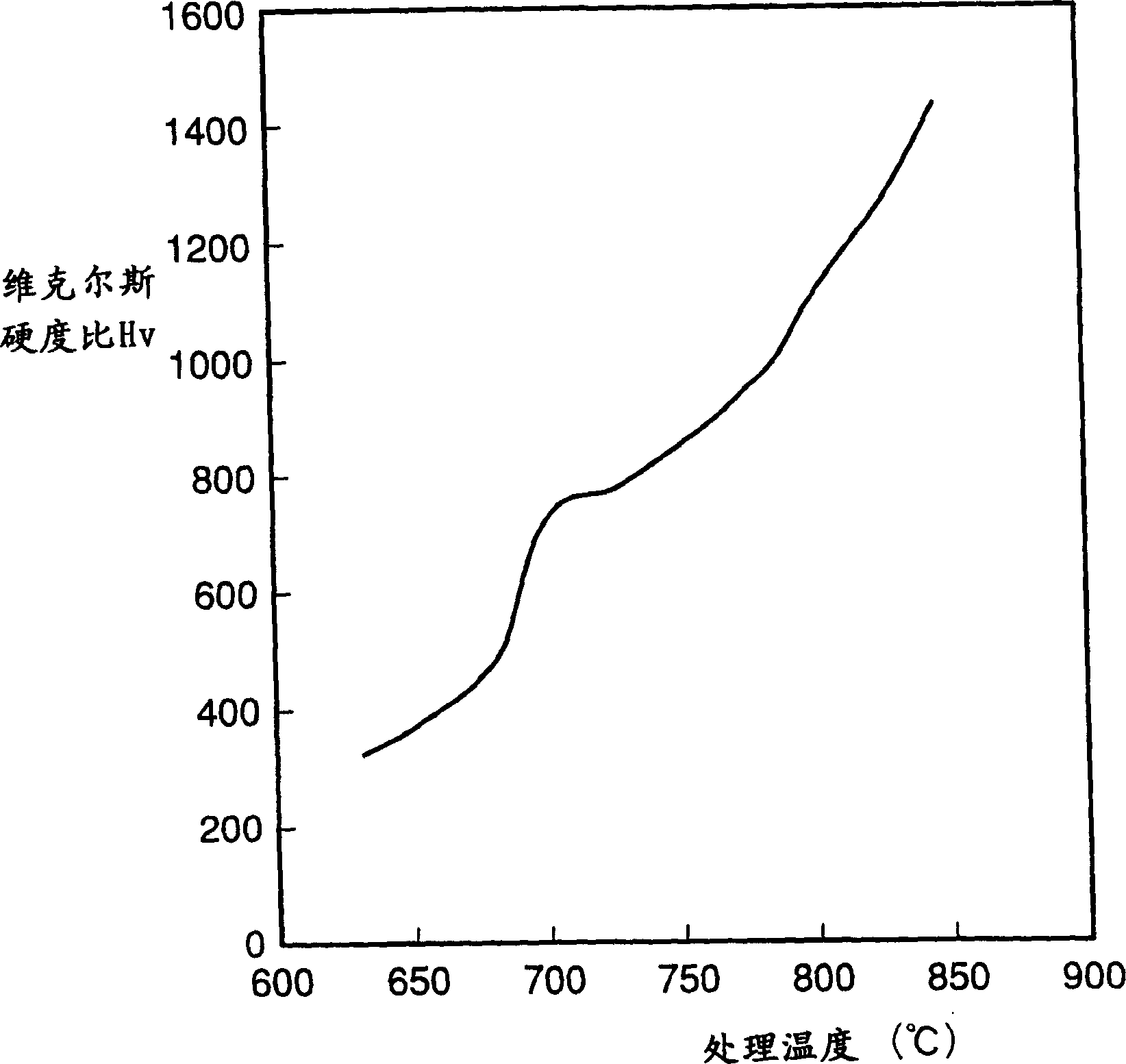

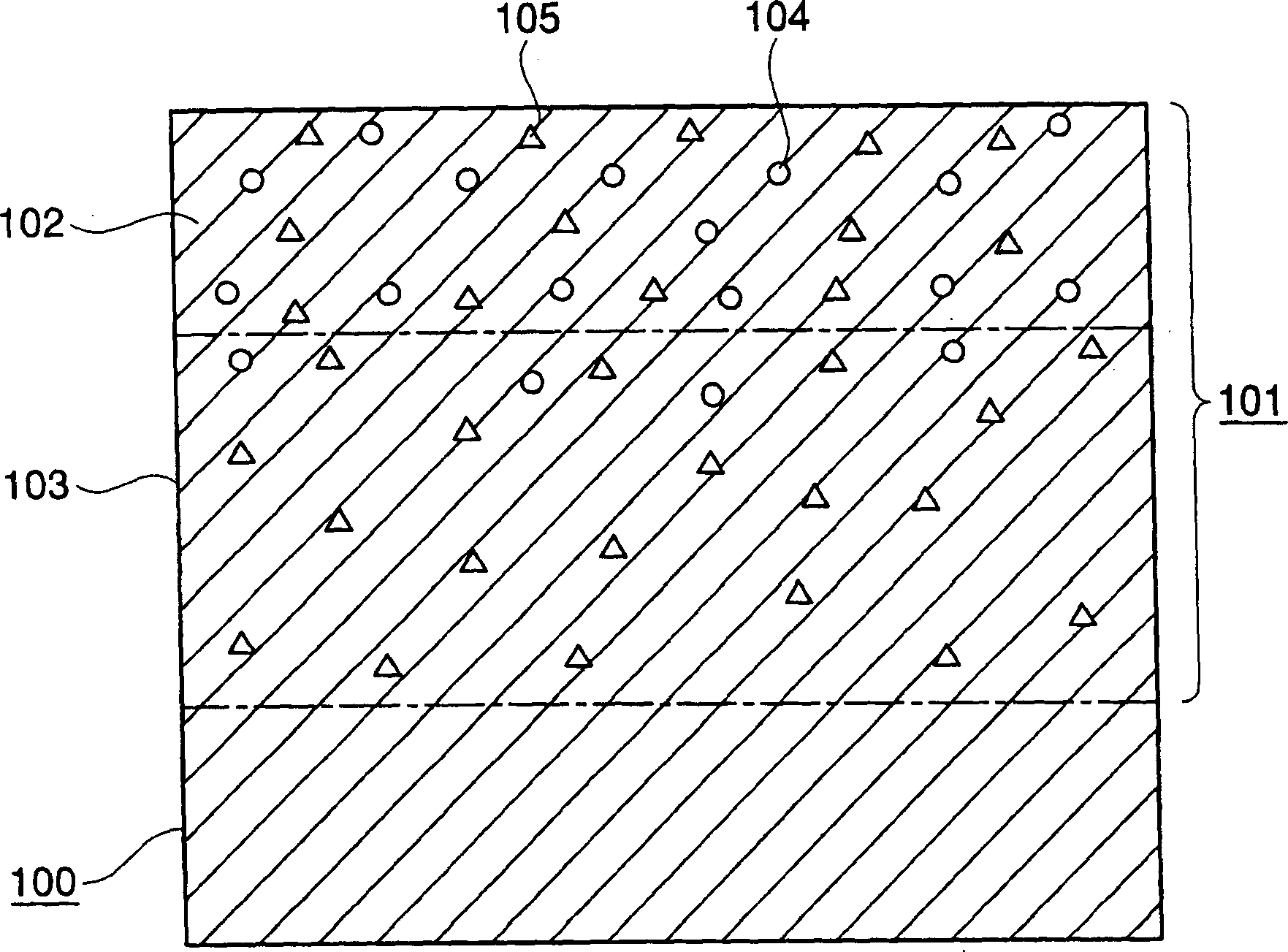

[0154] Such as figure 2 As shown, a surface hardened layer 101 is formed on the surface of titanium or titanium alloy tableware (hereinafter referred to as "titanium tableware) 100. Surface hardened layer 101 extends to a depth of about 20 microns from the surface. Surface hardened layer 101 is divided into first hardened layer 102 and a second hardened layer 103, nitrogen 104 and oxygen 105 diffuse in the first hardened layer 102 to form a solid solution, and oxygen 105 in the second hardened layer 103 diffuses to form a solid solution. It is observed that the first hardened layer 102 extends from the surface To a depth of about 1 micron, there is a second hardened layer 103 in a region deeper than this depth. Nitrogen 104 and oxygen 105 diffuse in the first hardened layer 102 to form a hardened layer that is particularly high in hardness and has th...

no. 2 approach

[0241] A second embodiment of the present invention is described below.

[0242] The purpose and basic function of each step of the second embodiment are the same as those of the aforementioned first embodiment. The second embodiment differs from the first embodiment in that the heating step and the hardening step are performed under atmospheric pressure. The second embodiment is also different from the first embodiment in that when the heating step is carried out under atmospheric pressure, an inert gas is introduced into the vacuum chamber to prevent the titanium tableware from reacting with impurity components other than nitrogen and oxygen components, because the titanium tableware Made of active metal.

[0243] In the heating step of the second embodiment, it is preferable to evacuate the vacuum chamber, then pass an inert gas into the vacuum chamber to adjust the pressure to atmospheric pressure, and the heating is performed under atmospheric pressure. However, it is a...

no. 3 approach

[0278] Refer below Image 6 A third embodiment of the present invention is described.

[0279] Image 6 Shown is the structural representation of the titanium tableware that the present invention makes. In this embodiment, by the ion plating method (that is, the dry plating method for making the titanium tableware 200), on the surface hardened layer 101 of the titanium tableware 100 produced by the first or second embodiment, a layer containing nitrogen is formed. The TiN coating film 201 of titanium oxide is used as a golden yellow hard coating film.

[0280] A method of forming the TiN coating film 201 of titanium nitride as the golden yellow hard coating film in this embodiment mode will be described below.

[0281] First, the titanium tableware 100 produced in the first or second embodiment is washed with an organic solvent such as isopropanol, and the titanium tableware is placed in an ion plating device (not shown). The ion plating device is a commonly used device, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com