Deep freezing device for effectively separating gas

A deep freezing and separation device technology, applied in household refrigeration devices, refrigerators, refrigeration components, etc., can solve problems such as high initial investment and operating costs, large evaporator load, and insufficient recovery of low-temperature air cooling capacity. , to achieve the effect of reducing initial investment, reducing operating costs, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

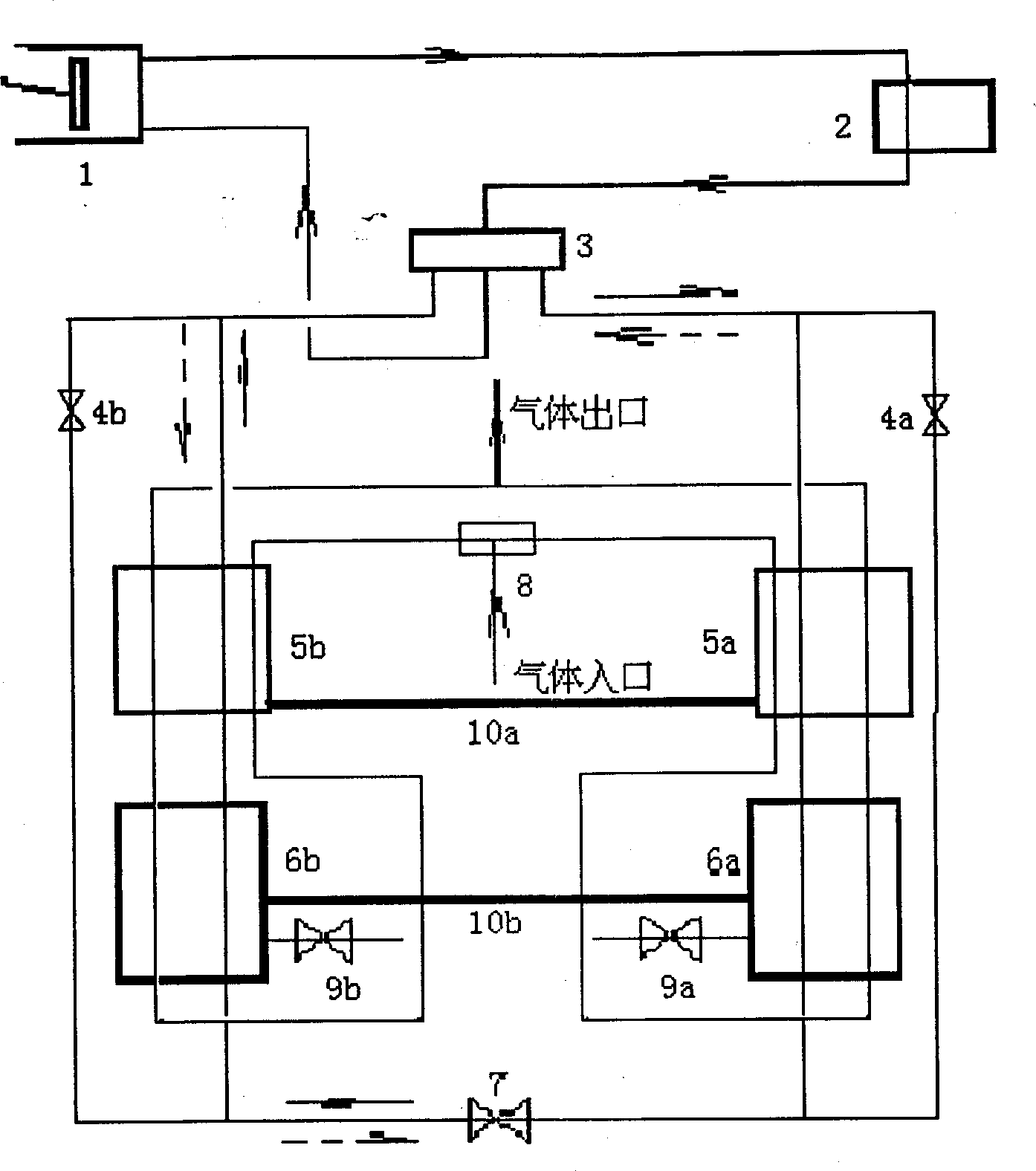

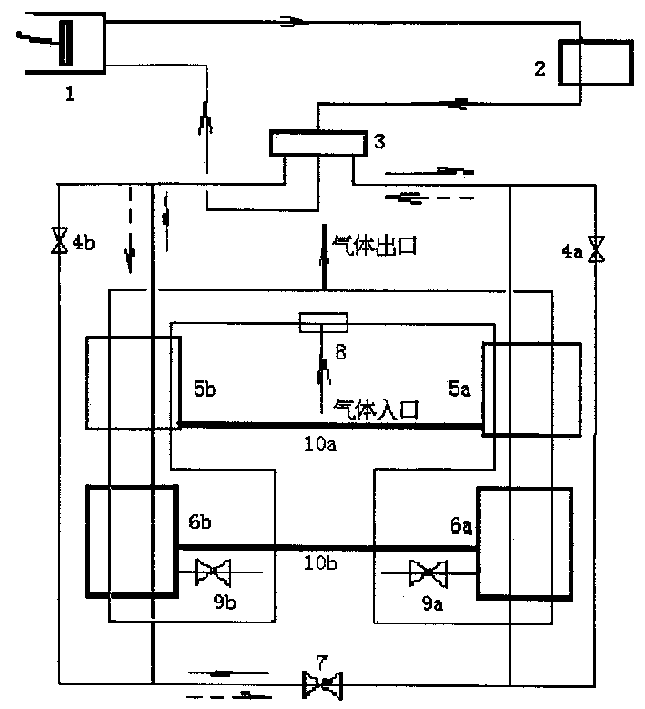

[0007] The device proposed by the present invention consists of compressor 1, condenser 2, four-way reversing valve 3, stop valves 4a and 4b, regenerators 5a and 5b, evaporators 6a and 6b, two-way expansion element 7, gas three-way valve 8 , Drain valves 9a and 9b and two cold bridges 10a and 10b.

[0008] The high-pressure outlet of compressor 1 connects with the high-pressure inlet of four-way reversing valve 3 through condenser 2, the low-pressure outlet of four-way reversing valve 3 connects with the low-pressure inlet of compressor 1, and one port of four-way reversing valve 3 passes through a Regenerator 5a, one evaporator 6a, two-way expansion element 7, another evaporator 6b, another regenerator 5b are connected to the other interface of four-way reversing valve 3, and the two ends of the two-way expansion element are respectively connected to four A shut-off valve 4a and 4b are respectively connected between the two ports leading to the reversing valve, thereby formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com