Control valve of high-pressure pneumatic switch

A technology of pneumatic switch and control valve, applied in the direction of lift valve, valve details, valve device, etc., can solve the research and application limitations of high-pressure pneumatic switch valve, high sealing difficulty, low lubricity and other problems, and achieve reliable sealing design performance, Easy operation and small throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

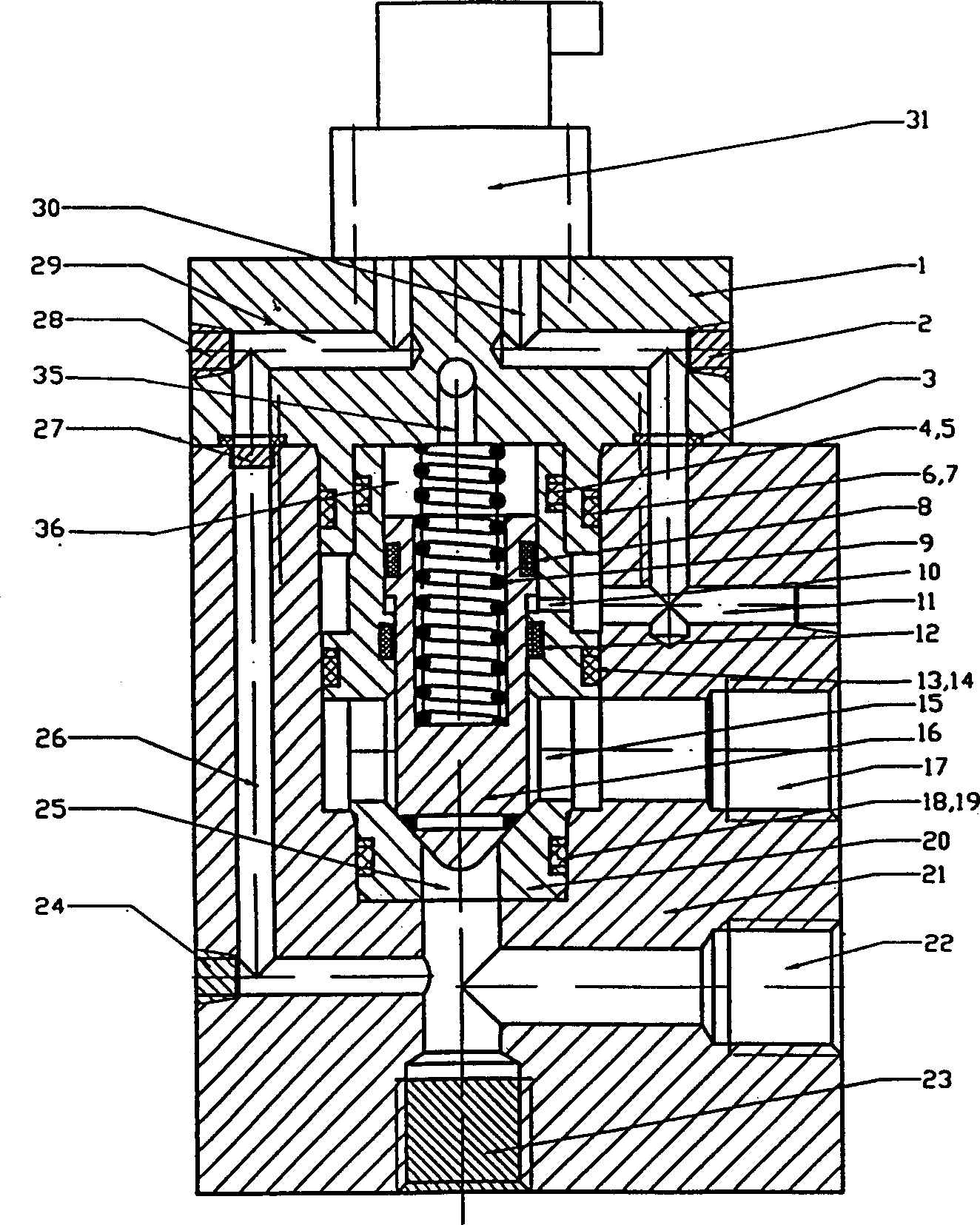

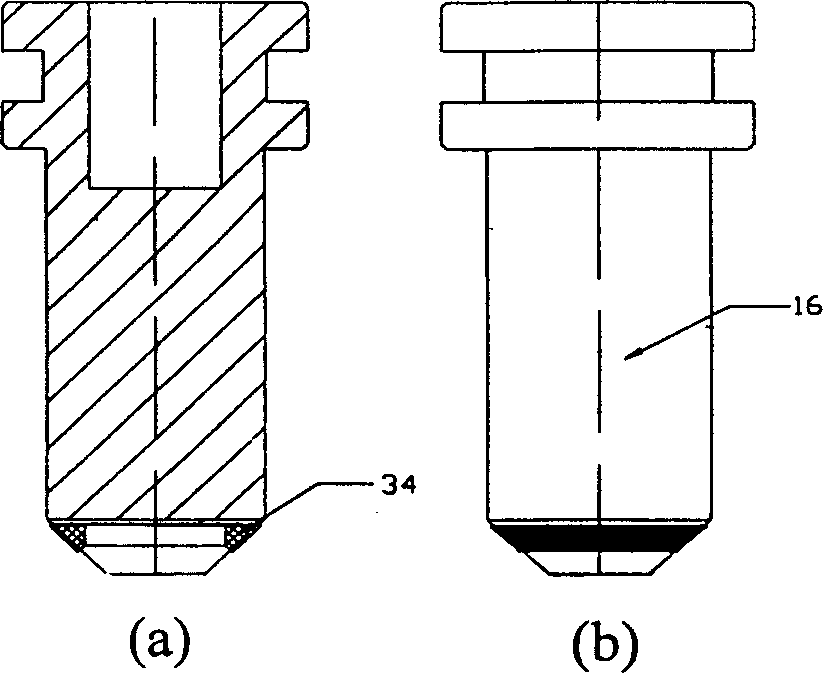

[0018] Such as figure 1 As shown, the high-pressure pneumatic switching valve is composed of an electromagnetic pilot valve part 31 and a main valve part. The pilot valve part is connected with the main valve part through an inner hexagon screw 33 . The pilot valve part adopts the electromagnetic ball valve with good sealing performance and high pressure resistance. The main valve part is composed of valve cover 1, cone valve core 16, valve sleeve 20, valve body 21 and other parts.

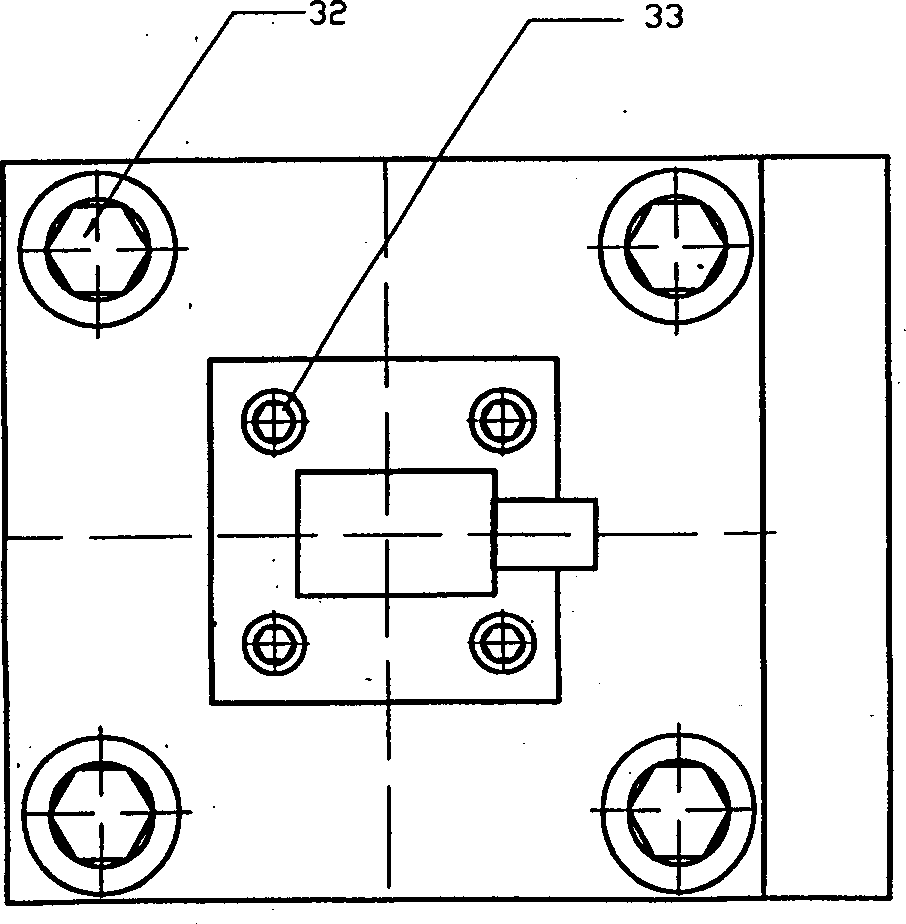

[0019] The bonnet part includes: such as figure 1 , figure 2 As shown, the plug 2 and the plug 28 installed on the bonnet 1, the seal ring 3 installed on the bonnet 1, the seal ring 6 and the retaining ring 7 installed on the bonnet 1, the control gas inlet channel 29 And control gas exhaust pressure relief passage 30. The valve cover 1 is installed in the valve body 21 and tightly connected by the hexagon socket head cap screw 32; the valve cover 1 and the valve body 21 are sealed by the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com