Technology for manufacturing commutator with cold-pressed end face and its product

A manufacturing method and commutator technology, applied in commutator manufacturing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

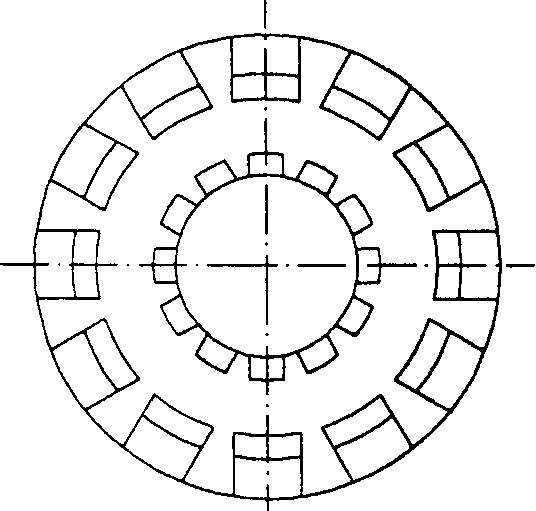

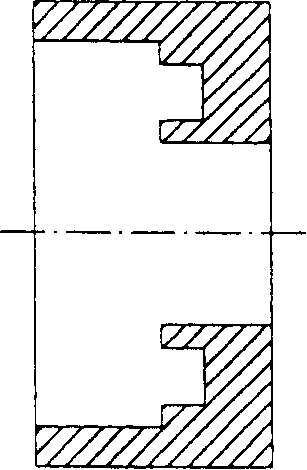

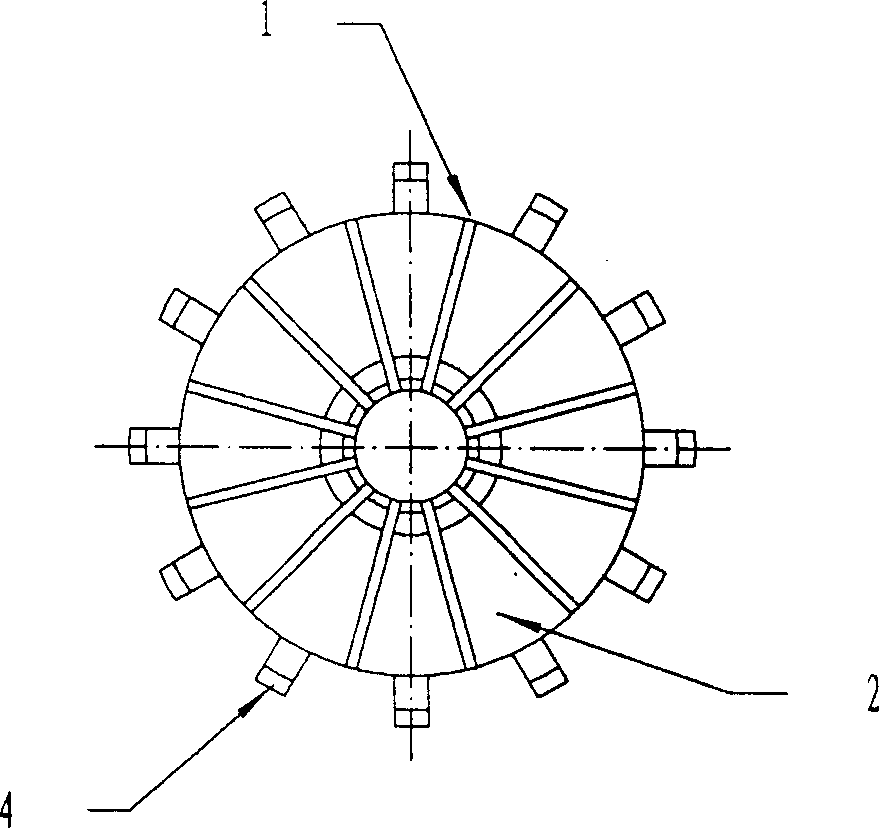

[0010] Accompanying drawing has shown technological process of the present invention, further describe the process of its embodiment in conjunction with subject matter of the present invention below again, the manufacture method of this cold extruded end face commutator, at first circular copper wire is cut according to design requirements, cutting The final copper section is extruded on a cold extrusion machine equipped with a mold, and the extruded copper section becomes the commutator blank (such as image 3 ), after pickling the blank, fill the cavity of the blank with bakelite powder 3, put it on the injection machine for injection molding, and the injection molding is to condense the thermosetting bakelite powder 3 and the blank together, Then the inner and outer circles are turned and trimmed, and the end face of the molded product is equally divided. After the equal division, the commutator segments 2 correspond to each other, and the corresponding bisectors are on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com