Piezoelectric electroacoustic transducer and mfg. method thereof

An electro-acoustic transducer and piezoelectric technology, applied in the direction of piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve the problems of frequency characteristic changes, low sound conversion efficiency, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

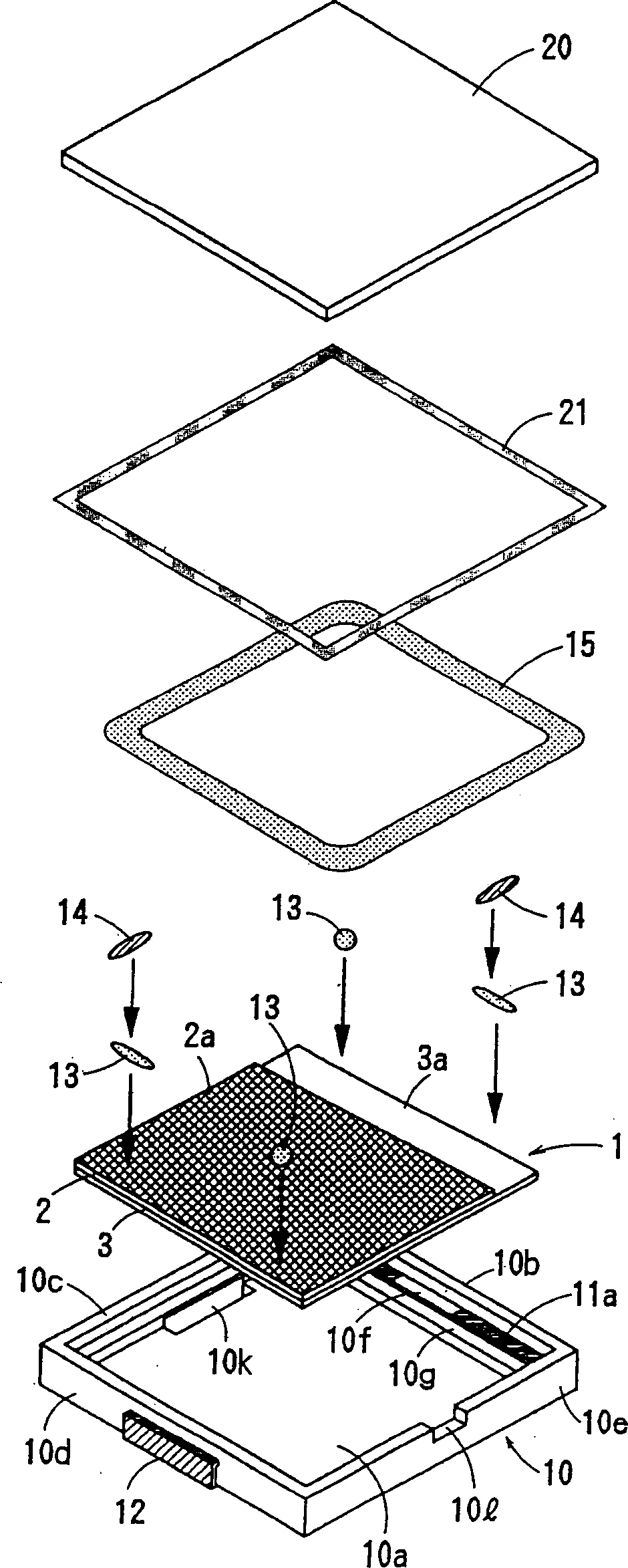

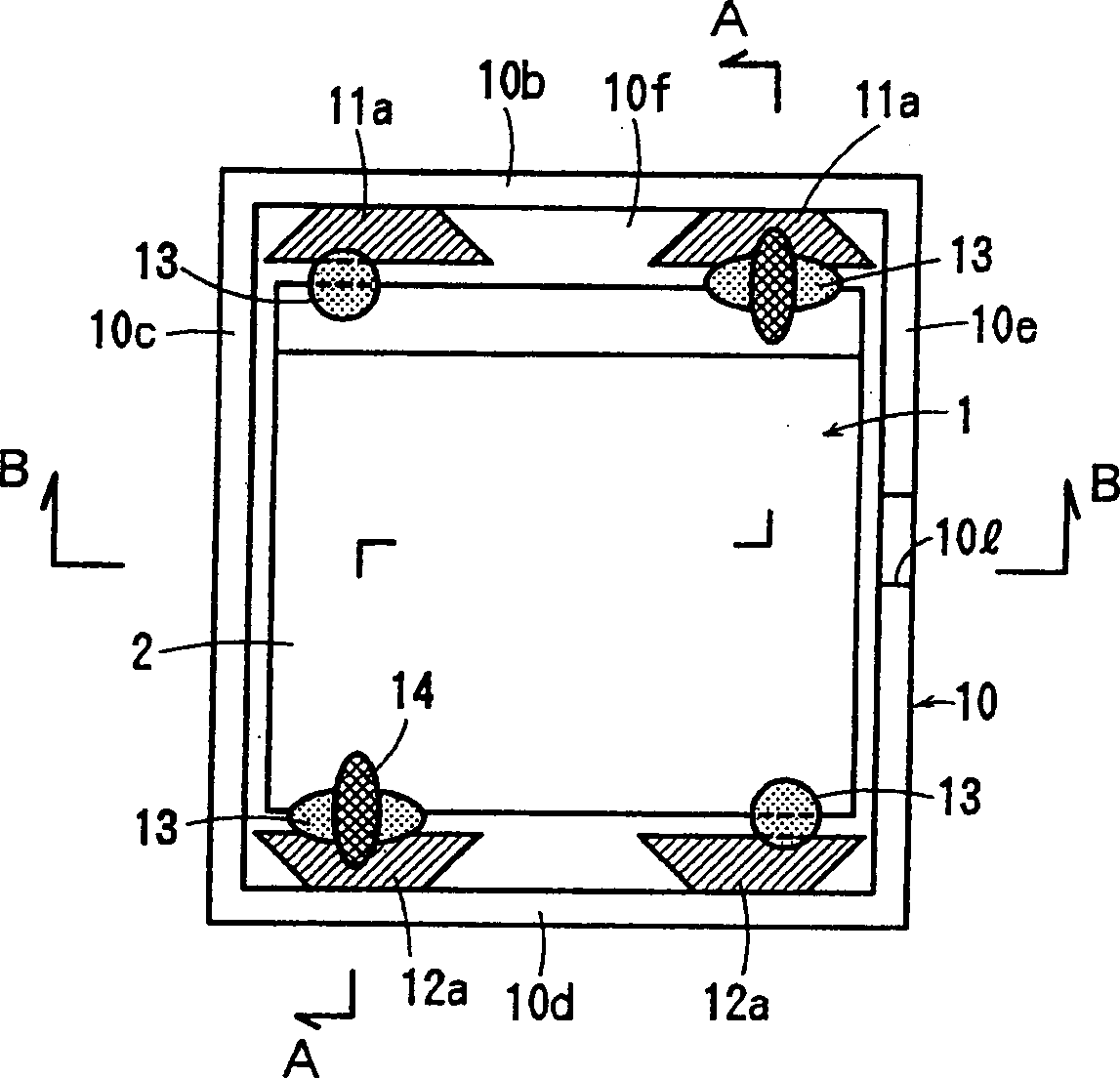

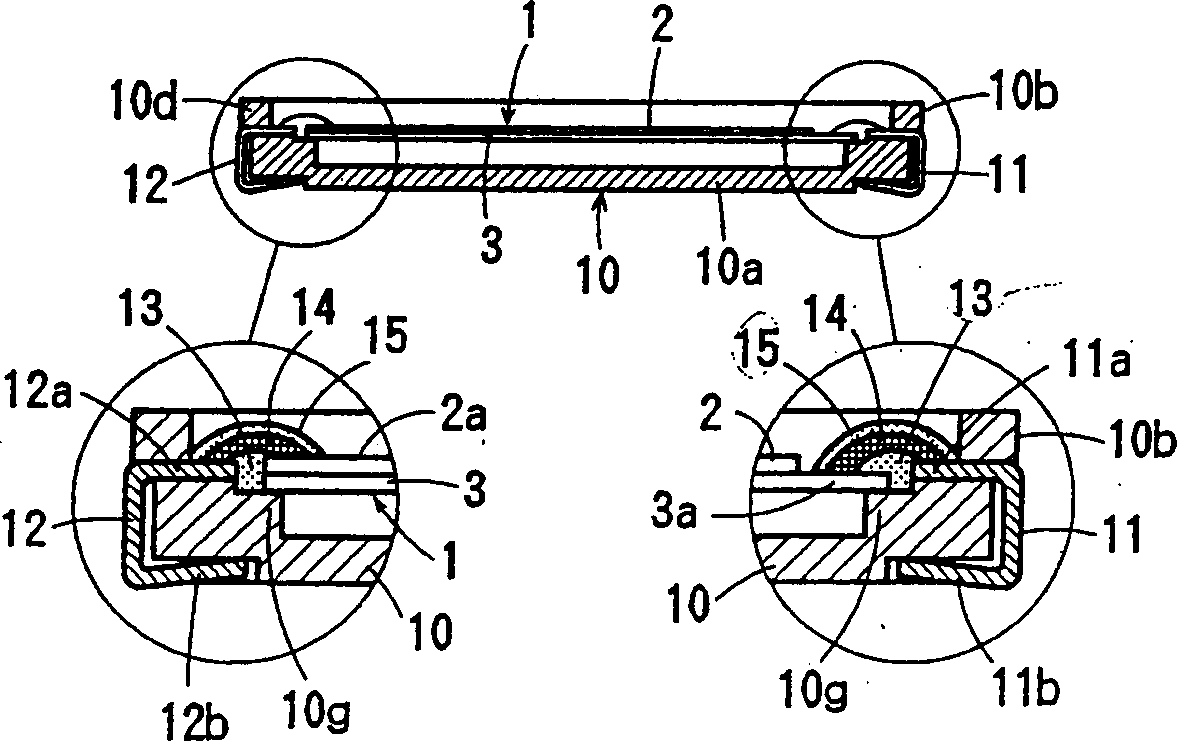

[0035] Figure 1-5 A surface mount piezoelectric electroacoustic transducer according to a first embodiment of the present invention is shown.

[0036] This electroacoustic transducer is suitable for use at a single frequency, such as a sounder and a ringer, and basically includes a unimorph type diaphragm 1 , a container 10 and a cover plate 20 .

[0037] Such as Figure 5 As shown, the diaphragm 1 includes: a square piezoelectric plate 2, which is polarized in the thickness direction, and has thin-film or thick-film electrodes 2a and 2b respectively formed on its top surface and back surface; and a rectangular metal plate 3, Its width is the same as that of the piezoelectric plate 2, but its length is slightly longer, and it faces the back surface electrode 2b of the piezoelectric plate 2, and is adhered thereto with a conductive adhesive. In addition, the metal plate 3 may be bonded directly on the back surface of the piezoelectric plate 2 with a conductive adhesive, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com