Mixed integrated circuit device and its manufacturing method

一种混合集成电路、制造方法的技术,应用在印刷电路制造、电路、印刷电路等方向,能够解决接合时间长、易折曲、Al细线弹性差等问题,达到提高散热性、解决现有问题的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

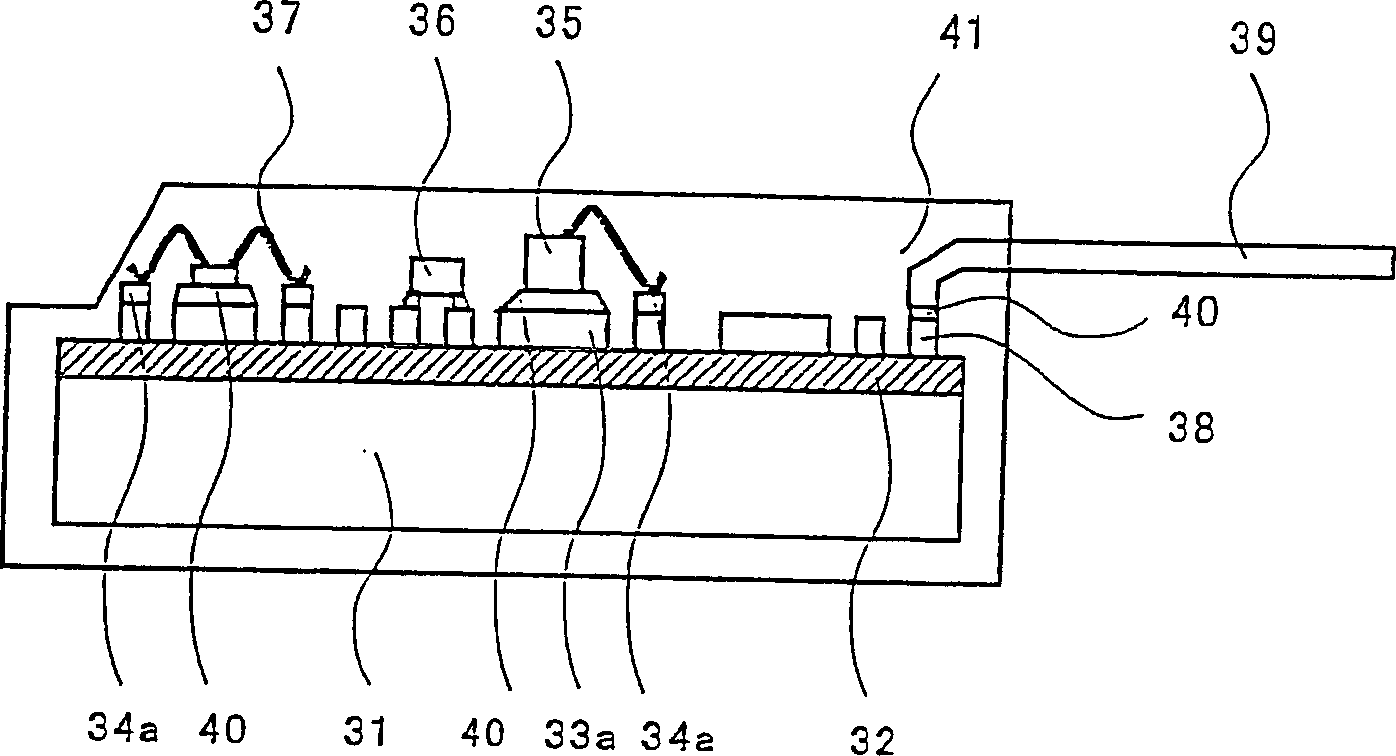

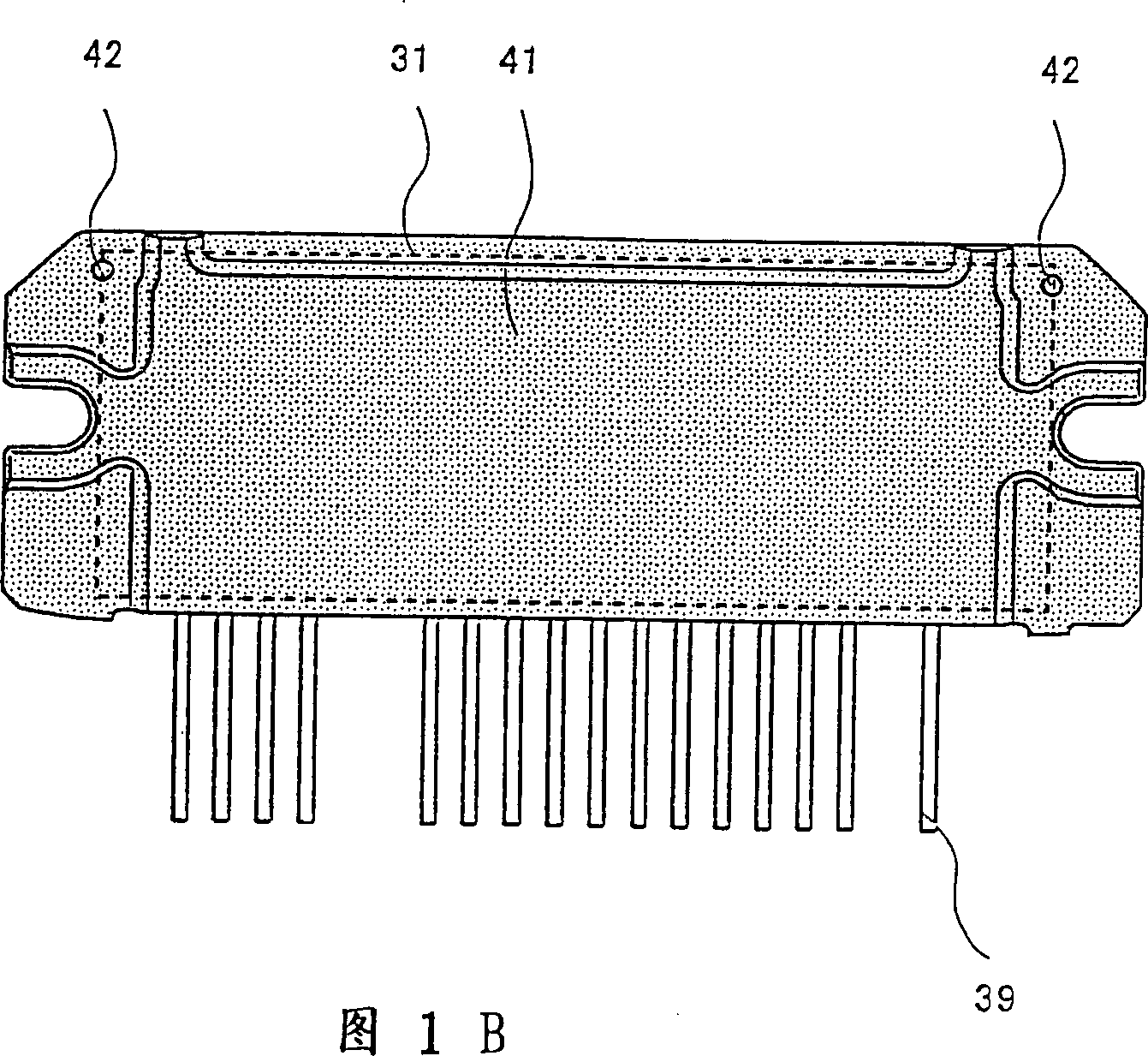

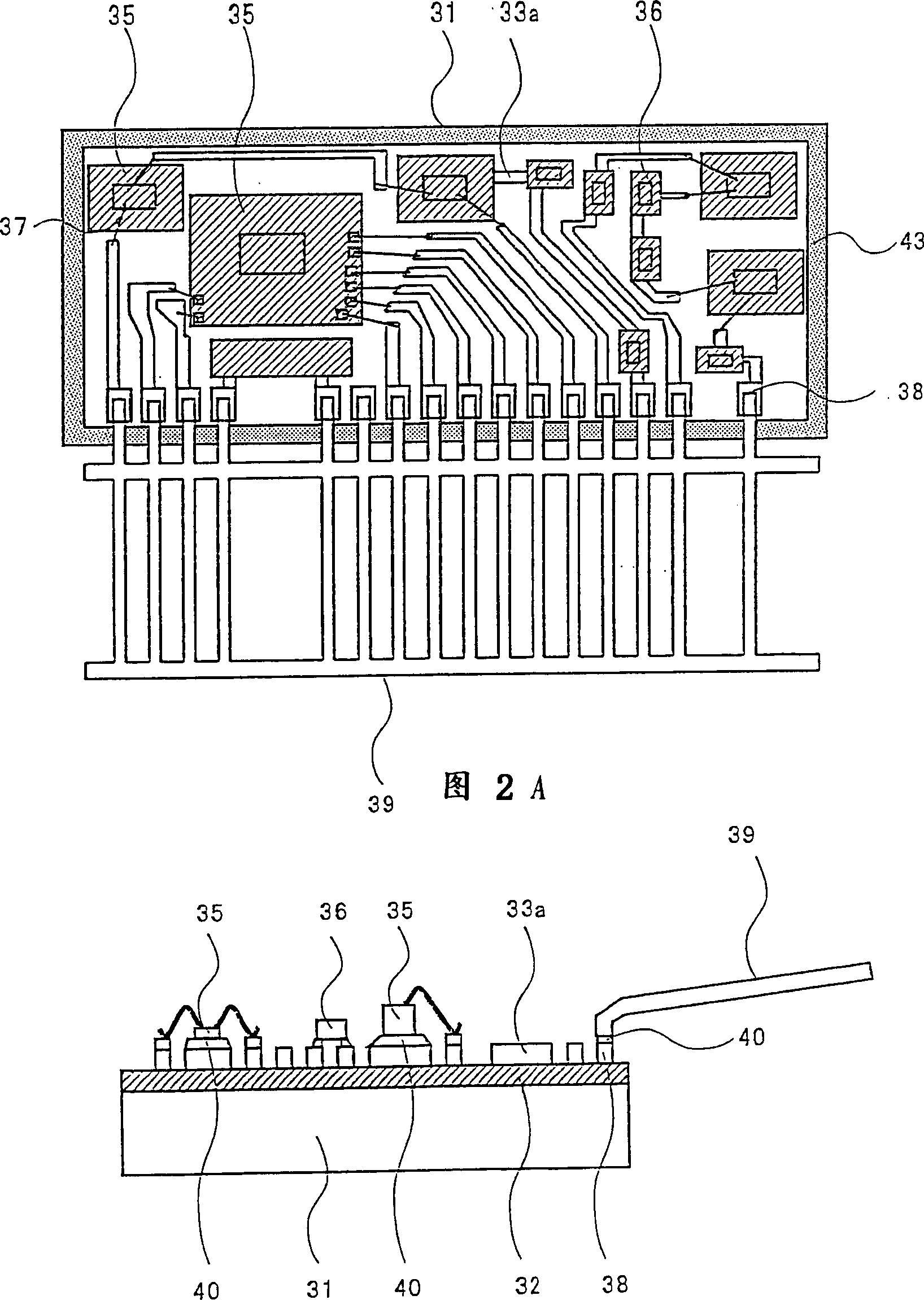

[0055] Below, refer to Figure 1A , Figure 1B and Figure 2A, Figure 2B A hybrid integrated circuit device according to Embodiment 1 of the present invention will be described.

[0056] First, refer to Figure 1A , FIG. 1B illustrates the structure of the hybrid integrated circuit device. Such as Figure 1A As shown, the hybrid integrated circuit device 31 adopts a substrate with good heat dissipation in consideration of heat generated by semiconductor elements etc. fixedly mounted on the substrate 31 . In this embodiment, the case where the aluminum substrate 31 is used will be described. In addition, although an aluminum (hereinafter referred to as Al) substrate is used for the substrate 31 in this embodiment, it does not need to be particularly limited. For example, this embodiment can also be realized by using a printed circuit board, a ceramic substrate, a metal substrate, etc. as the substrate 31 . Moreover, a copper substrate, an iron substrate, an iron-nickel sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com