Electronic part loading state detection device

A technology of electronic components and loading state, applied in the direction of measuring devices, optical device exploration, instruments, etc., can solve the problems of high price, rising production cost, long analysis time, etc., and achieve the effect of saving cost, improving accuracy and fast analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

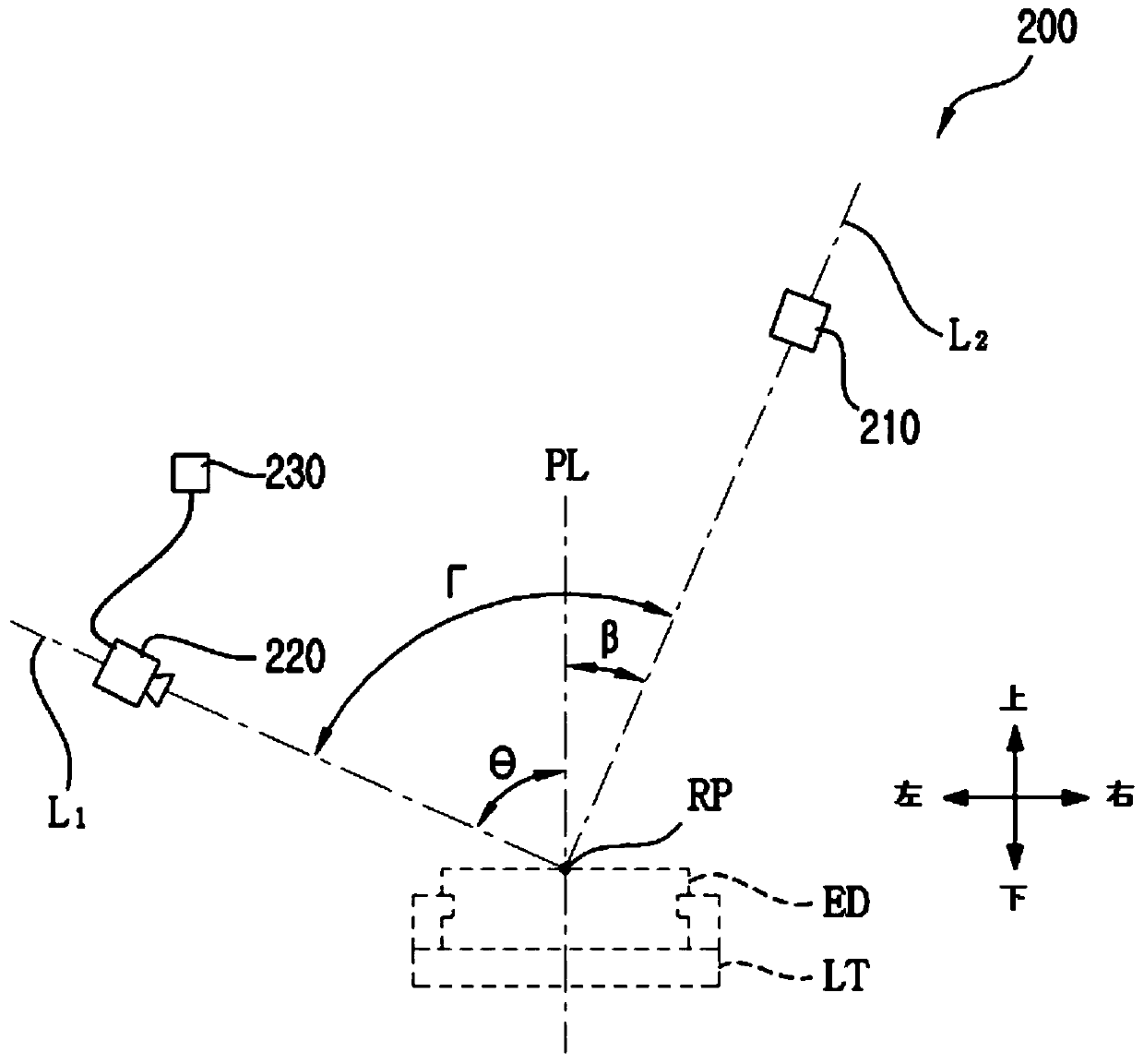

[0073] Such as Figure 12 As shown, the detection device 200 (the solid line part) according to this embodiment includes four light irradiators 210a to 210d, four cameras 220a to 220d, an analyzer 230 and two regulators.

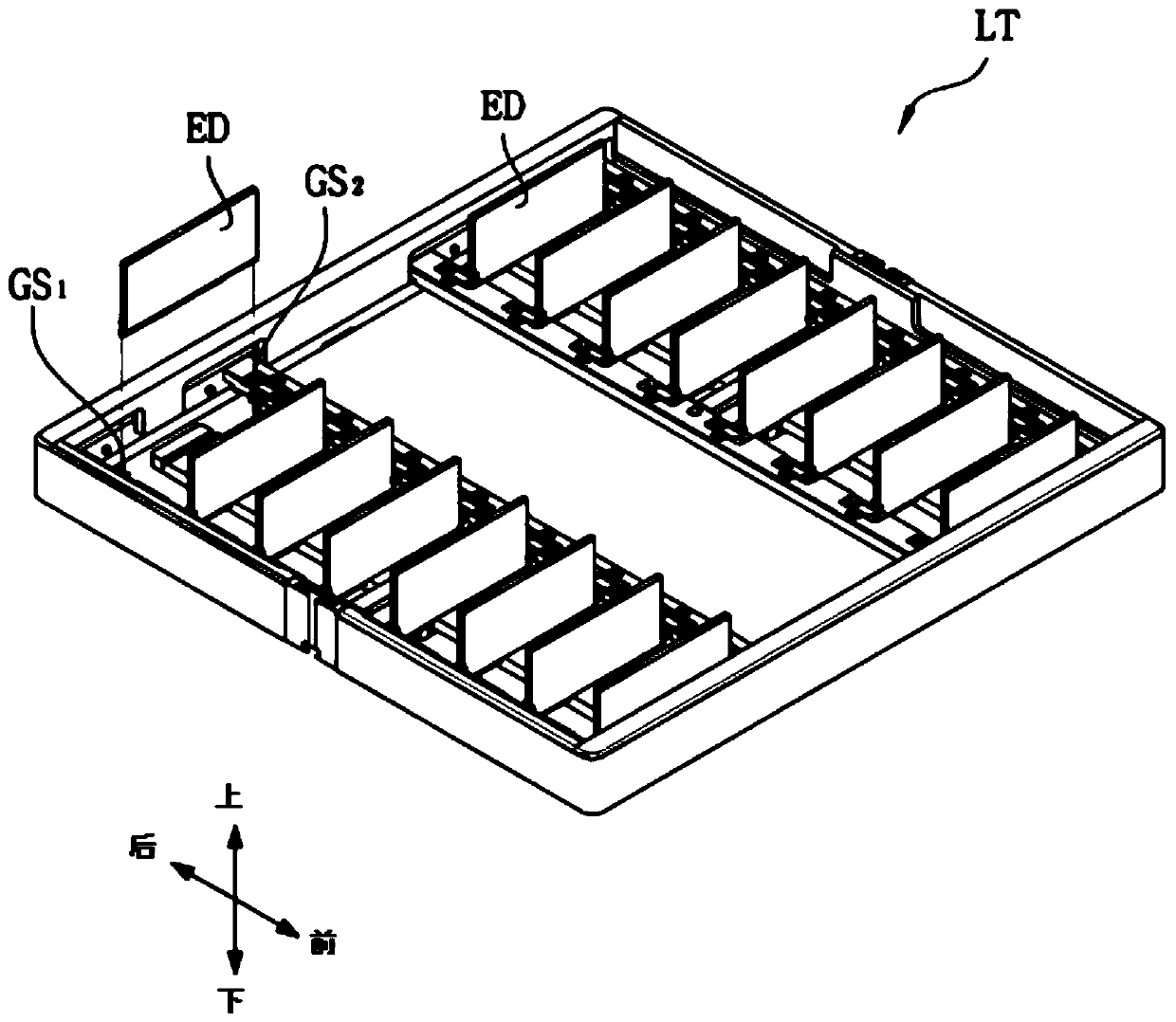

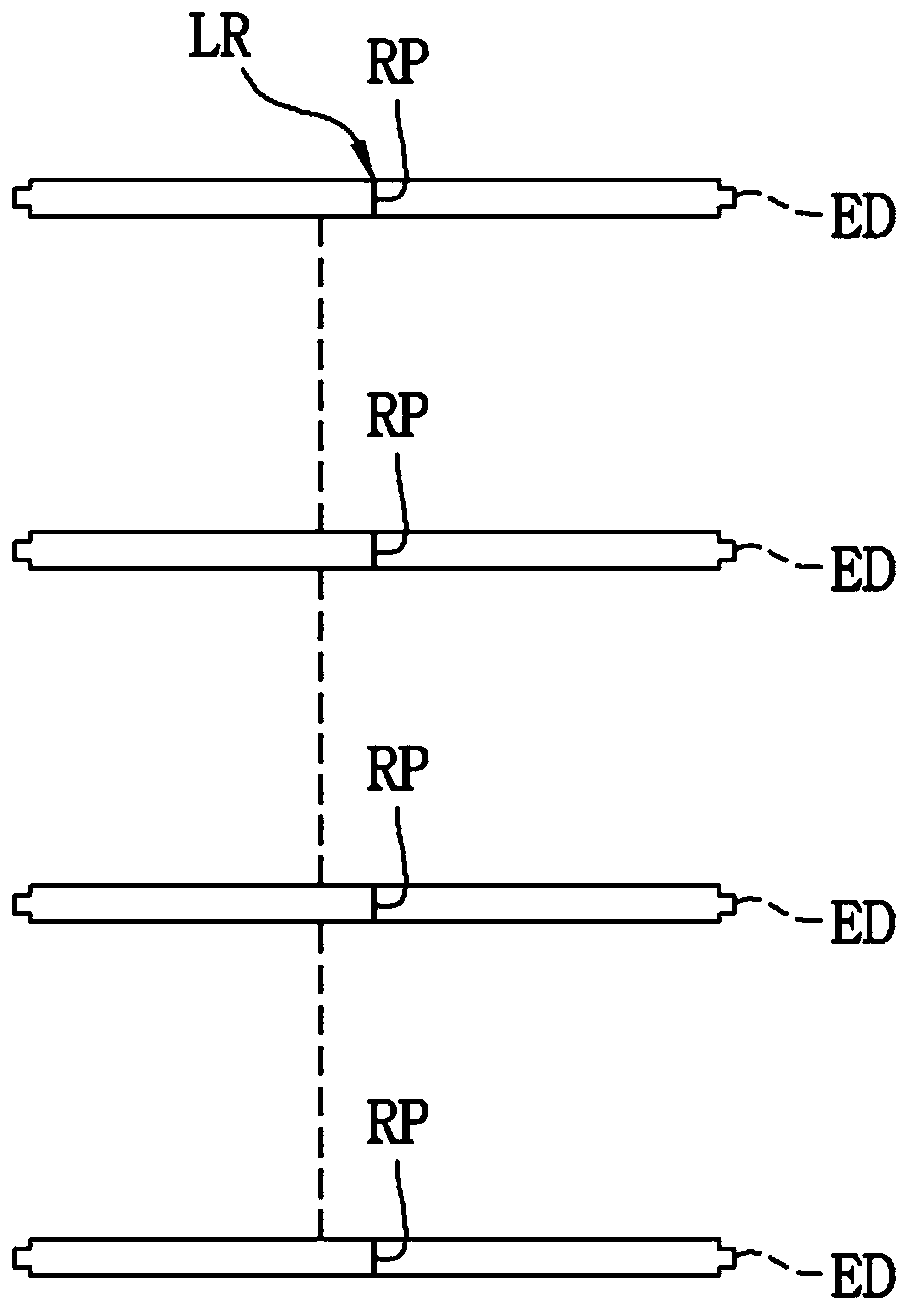

[0074] The four light irradiators 210 a to 210 d are used to irradiate linear laser light to the electronic components ED of the loading tray LT located below. Among them, the loading tray LT as according to figure 1 The embodiment of the present invention is loaded with sixteen electronic components in the form of 8x2 rows and columns and in a vertical state.

[0075] Among the four photoirradiators 210a to 210d, the right two photoirradiators 210a and 210b are used to irradiate laser light to a plurality of electronic components ED in the left column, and the left two photoirradiators 210c and 210d are used to irradiate laser light to the right column. Multiple electronic components ED are irradiated with laser light. In this way, the photoirradiators 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com