Crystal form of Pifuadefuwei

A crystal form and crystallization technology, applied in the field of crystal form of pivo adefovir, which can solve the problems of flammability and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

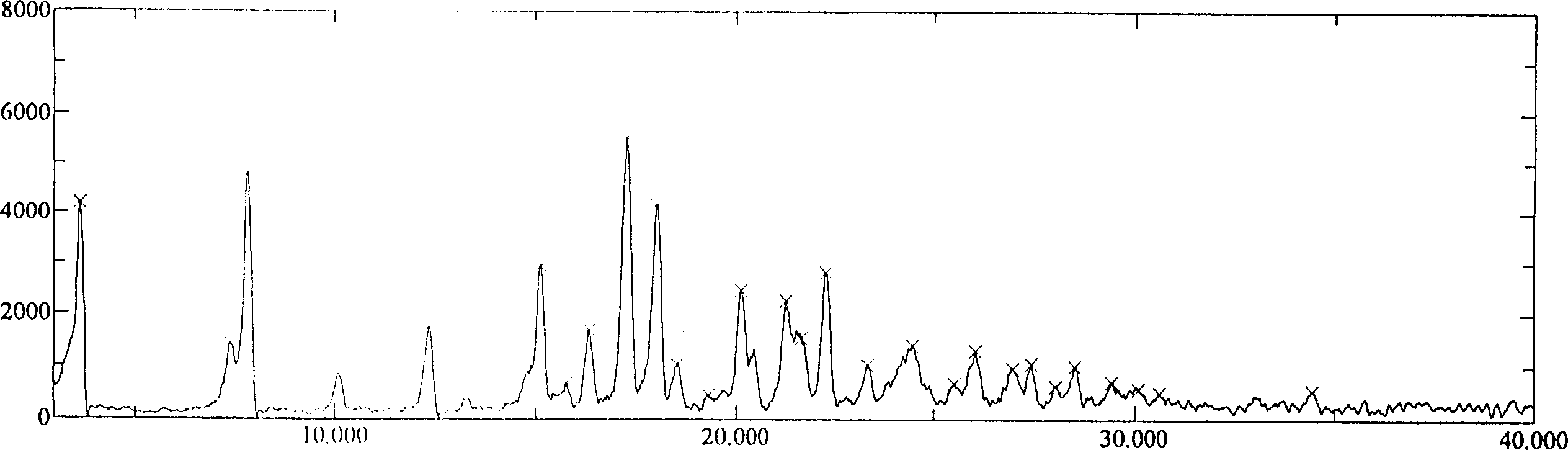

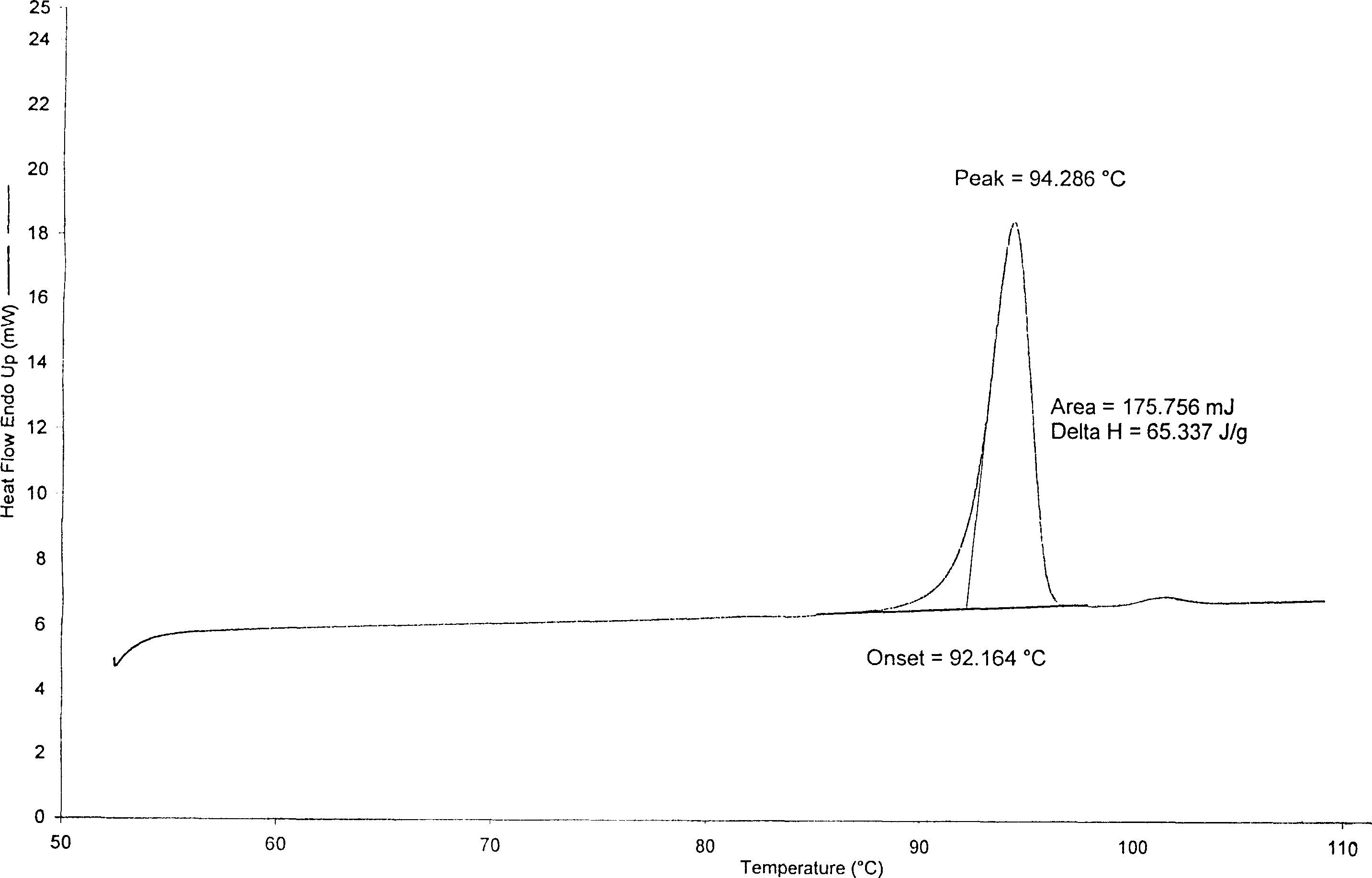

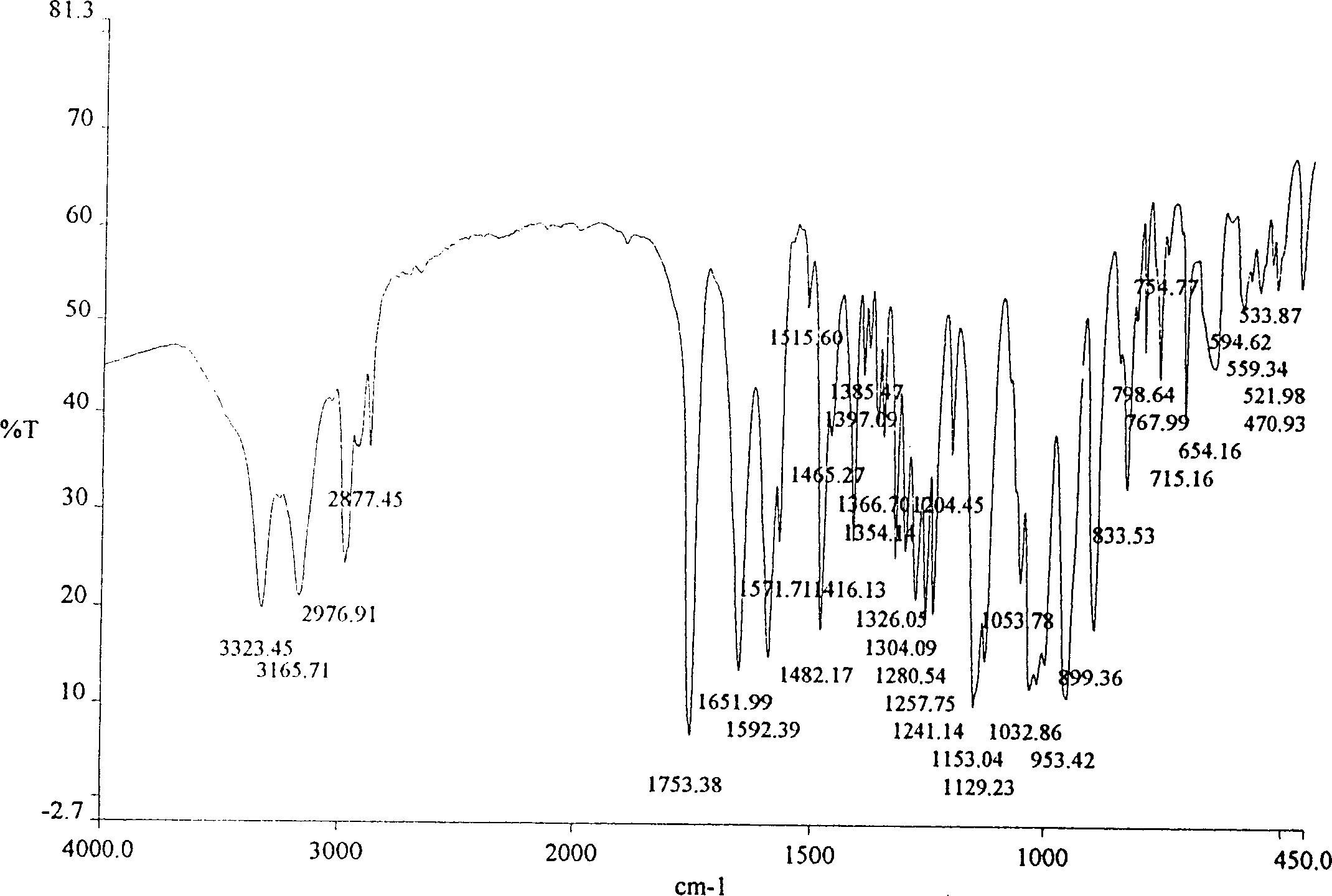

Image

Examples

Embodiment 1

[0044] 9-(2-phosphonomethoxyethyl)-adenine purification method:

[0045] In a 100L reaction pot, add 1.0Kg of 9-(2-phosphonomethoxyethyl)-adenine crude product into 50L of water, heat to reflux, after dissolving, keep the temperature, add 100g of activated carbon for decolorization for 10min, filter, Let cool to crystallize, filter, and dry the crystals at 80°C to obtain the pure product.

Embodiment 2

[0047] Preparation of Adefovir Pivovir Form E

[0048] In a 10L reaction pot, suspend 0.5Kg (1.8mol) of purified 9-(2-phosphonomethoxyethyl)-adenine in 5L N,N-dimethylformamide, stir, add 1.044KgN, N-dicyclohexyl-4-morpholine, 100ml of triethylamine and 1.382Kg (9.2mol) chloromethyl pivalate, heated up to 50°C, kept stirring for 3 hours, filtered off the insoluble matter, and the filtrate was vacuum-0.1 Concentrate under reduced pressure at Mpa, and extract the concentrate with toluene (10L×2). Recover toluene under reduced pressure at vacuum degree -0.1Mpa, add 5L of pure water to the remaining oily liquid, stir for 5 hours, a large amount of white solid precipitates, filter it out, dissolve it in 1.5L of anhydrous methanol, add anhydrous Stir 1.0Kg of magnesium sulfate for 2 hours, filter, add 50g of activated carbon to the mother liquor, decolorize at 50°C for 10min, take an external bath at 50°C, evaporate to dryness under reduced pressure to obtain a white solid, and dry...

Embodiment 3

[0050] Preparation of Adefovir Pivovir Form E

[0051] In a 10L reaction pot, suspend 0.5Kg (1.8mol) of purified 9-(2-phosphonomethoxyethyl)-adenine in 5L N,N-dimethylformamide, stir, add 1.044KgN, N-dicyclohexyl-4-morpholine, 100ml of triethylamine and 1.382Kg (9.2mol) of chloromethyl pivalate, heated up to 50°C, kept stirring for 3 hours, filtered off the insoluble matter, and vacuum-0.1Mpa Concentrate under reduced pressure, and extract the concentrate with toluene (10L×2). Recover toluene under reduced pressure at vacuum degree -0.1Mpa, add 0.5L of ethanol to the remaining oily liquid, stir to dissolve the oily matter, then add 4L of water, stir for 5 hours, a large amount of white solid precipitates, filter it out, and dissolve it in In 1.5L of anhydrous methanol, add 1.0Kg of anhydrous magnesium sulfate, dry the water, filter, add 50g of activated carbon to the mother liquor, decolorize at 50°C for 10min, use an external bath at 60°C, evaporate to dryness under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com