Process of preparing 10-deacetyl Bakatin III from taxad branch and leaf residue

A technology of acetyl bacca and yew leaves, applied in chemical recovery, organic chemistry, etc., can solve the problems of difficulty in improving the purity, low yield of crystallization method, waste of resources, etc., and achieve environmental protection, low cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

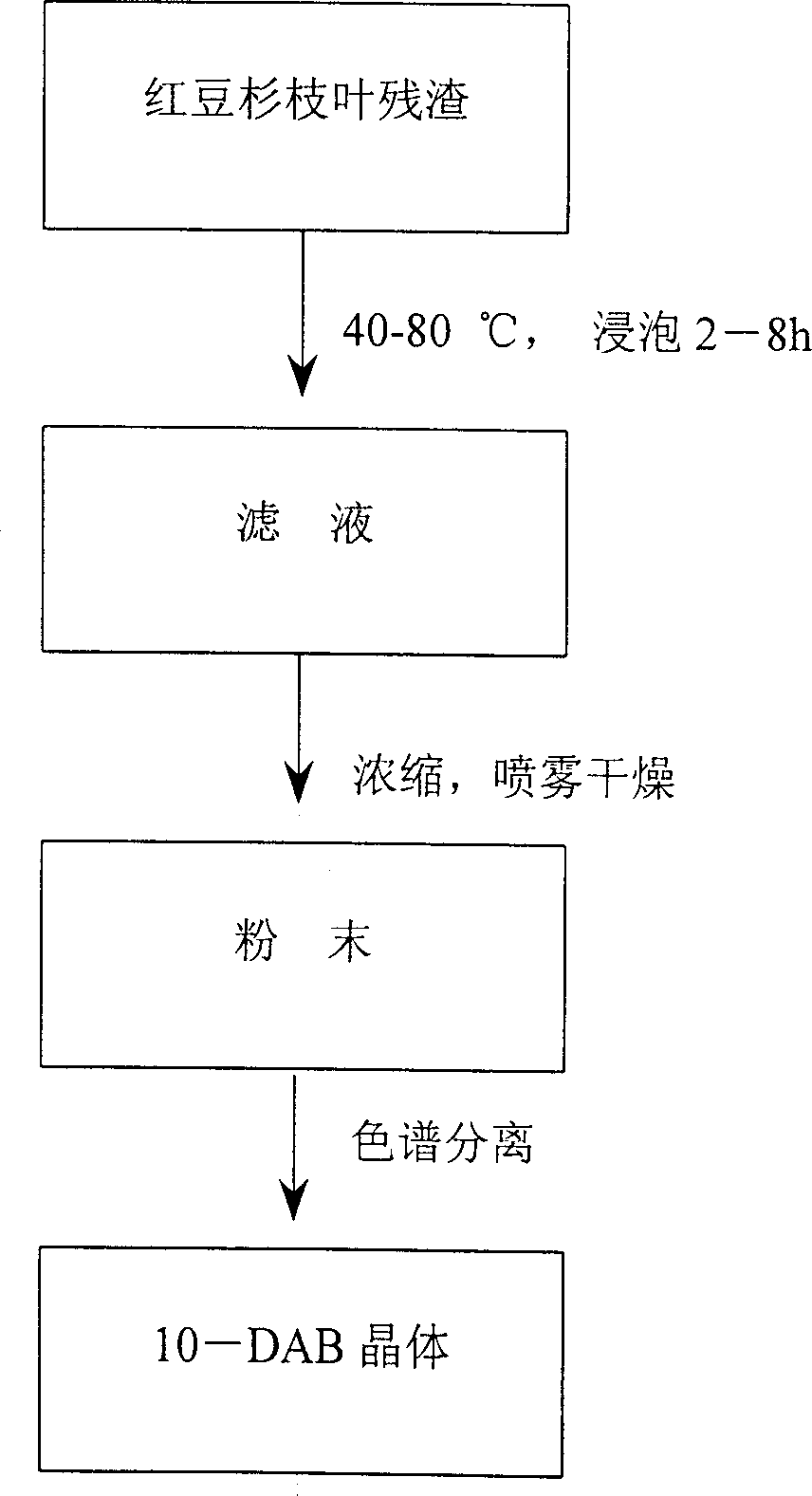

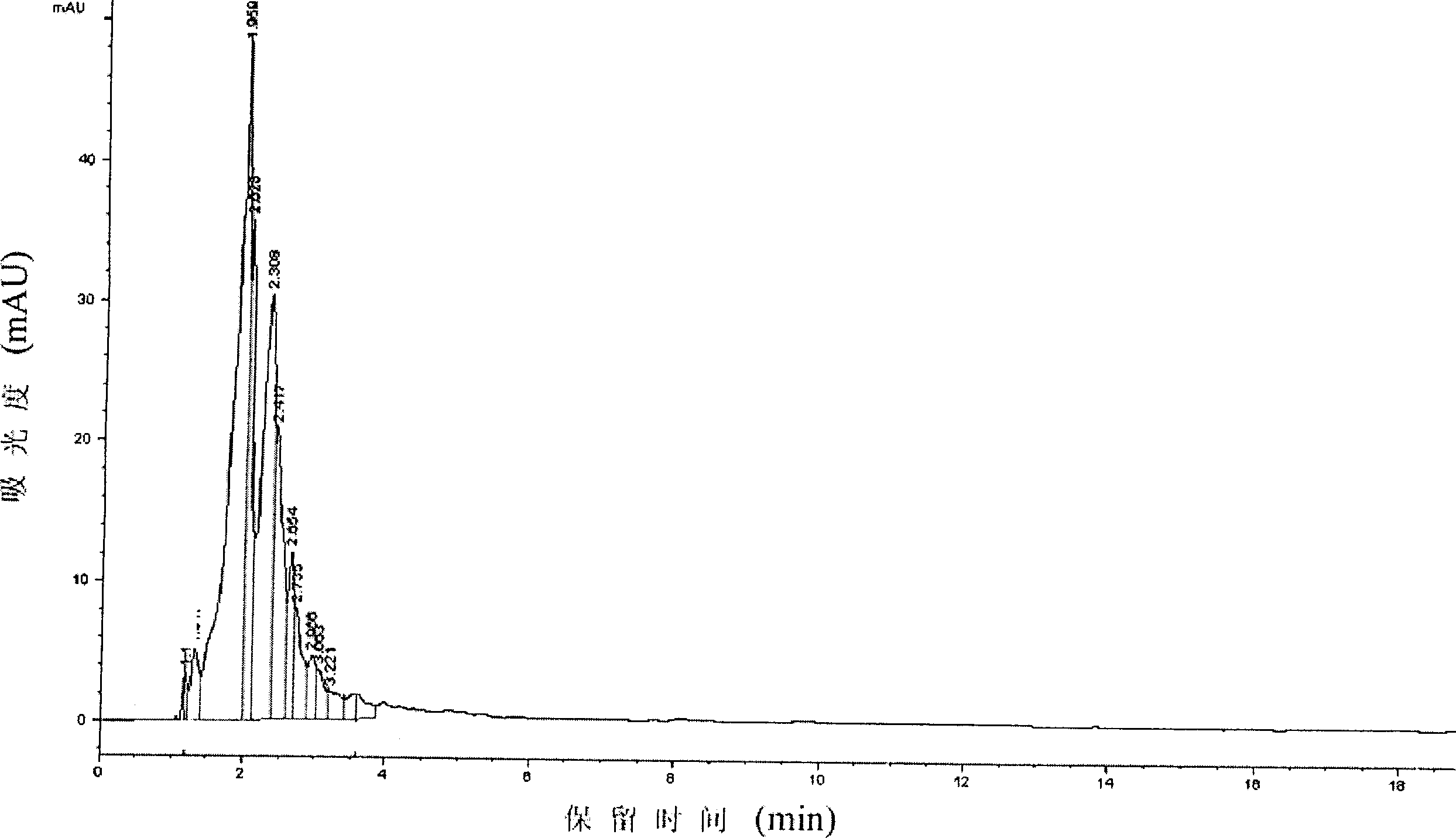

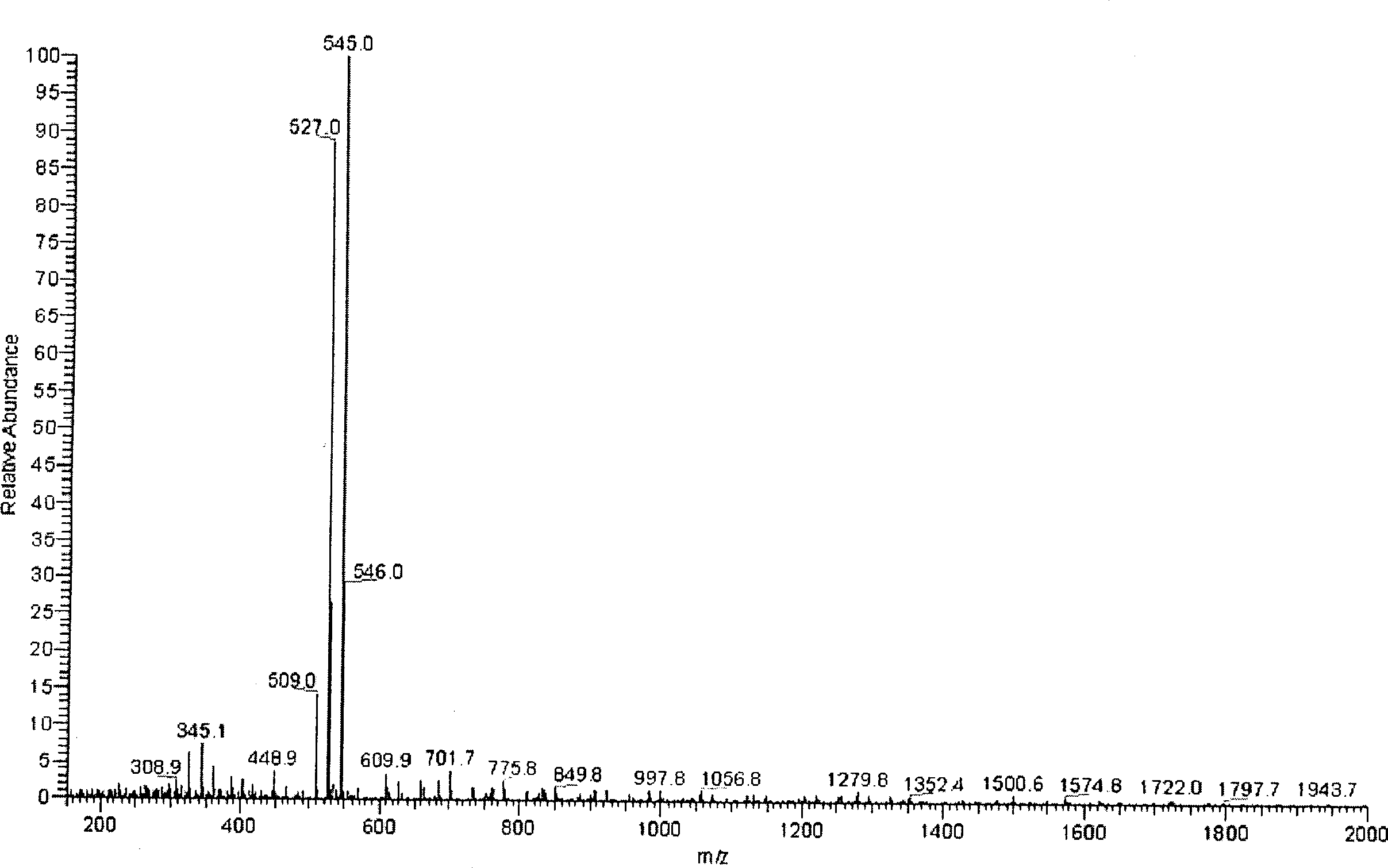

[0023] like figure 1 , a scheme for the preparation of 10-desacetylbaccatin III. Take 1kg of the residue after paclitaxel was extracted from the leaves and branches of the planted yew, put it in a drying oven, heat it to 70°C and dry it under vacuum for 24 hours to obtain 927g of dry solid, grind it into 100 mesh powder, put it into a 5 liter wide mouth bottle, add 4 liters of water, soak in a water bath at 50°C for 4 hours, extract multiple times, combine the extracts, filter and concentrate, and spray dry to obtain 236g of powder, such as figure 2The high-performance liquid chromatography of the material obtained after the yew branch and leaf residue is boiled shows that it is 0.22g crude extract of 10-deacetylbaccatin III crystal, which is dissolved in 300ml ethyl acetate, and the sample is loaded by dry method. : 1 ethyl acetate and hexanaphthene rinse 30L, collect eluate segmentally, obtain the 10-deacetylbaccatin III crystal 0.22g that purity is 99.5%, see image 3 , ...

Embodiment 2

[0025] Take 1 kg of the residue after paclitaxel was extracted from the leaves and branches of the planted yew, put it in a drying oven and heat it to 70 ° C for 36 hours in vacuum to dry to obtain 911 g of dry solid, grind it into 100 mesh powder, put it into a 5 liter wide mouth bottle, add 4 liters of water, soak in 80°C water bath for 2 hours, extract multiple times, combine the extracts, filter and concentrate, spray dry to obtain 213g powder, dissolve in 300ml ethyl acetate, dry load, use 1:1 ethyl acetate Esters and cyclohexane rinsed 30 L, and the eluent was collected in sections to obtain 0.25 g of 10-deacetylbaccatin III crystals with a purity of 99.6%.

Embodiment 3

[0027] Take the leaves and branches of the planted Taxus chinensis and extract 10kg of the residue after paclitaxel is extracted, put it in a drying oven and heat it to 70°C for 36 hours in vacuum to dry to obtain 9217g of dry solid, grind it into a 100-mesh powder, put it into the extraction tank, add 45 liters of water, soaked in a water bath at 80°C for 3 hours, extracted several times, combined the extracts, filtered and concentrated, spray-dried to obtain 3215g powder, dissolved in 3L ethyl acetate, and applied dry method several times, using 1:1 ethyl acetate Rinse with cyclohexane, collect the eluent in sections, and obtain 2.98 g of 10-deacetylbaccatin III crystals with a purity of 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com