Planar CRT panel

A planar cathode and ray tube technology, applied in the direction of cathode ray tube/electron beam tube, cathode ray/electron beam tube shell/container, discharge tube, etc., can solve problems such as cracking, thick flat panel, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

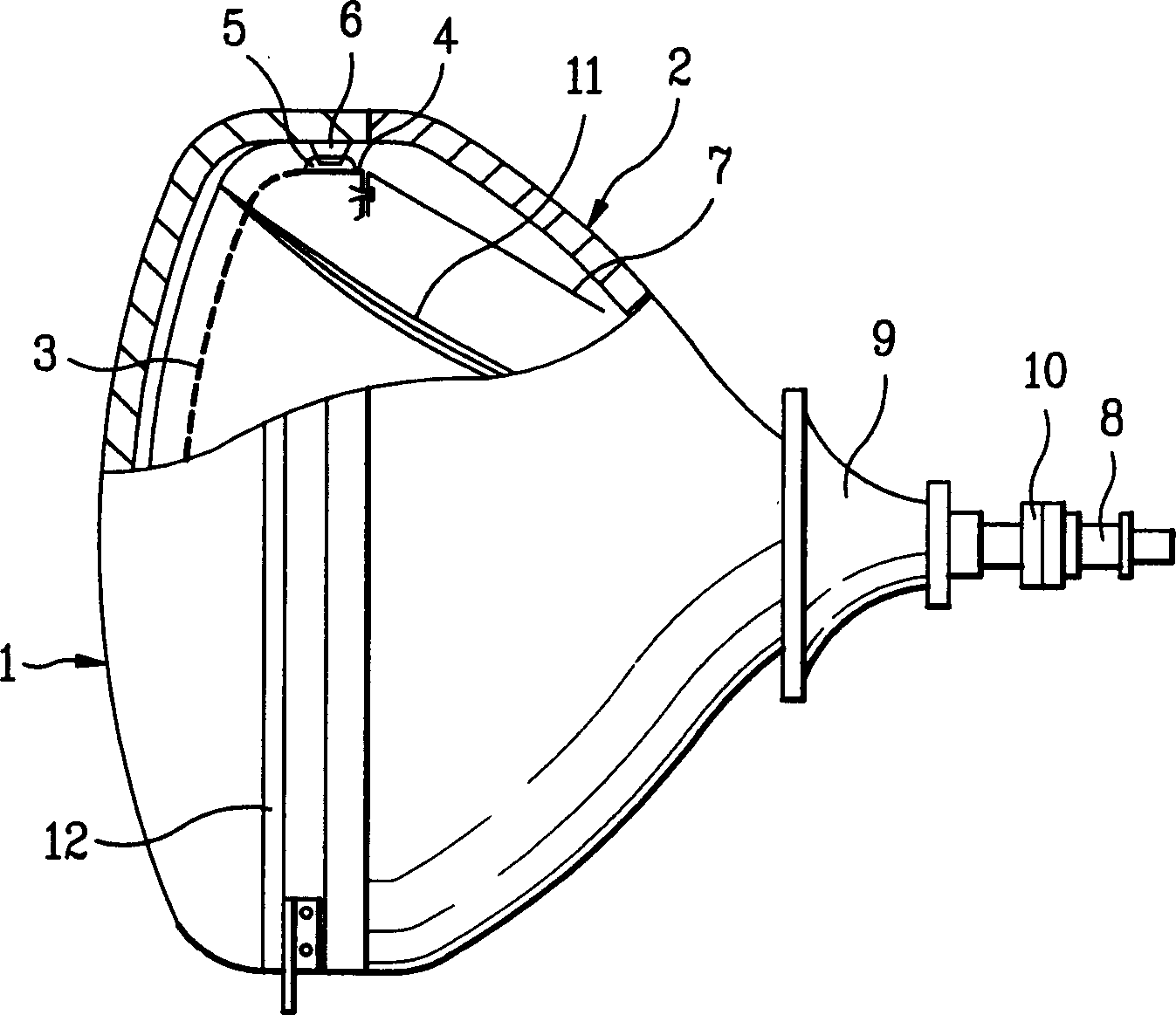

[0034] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

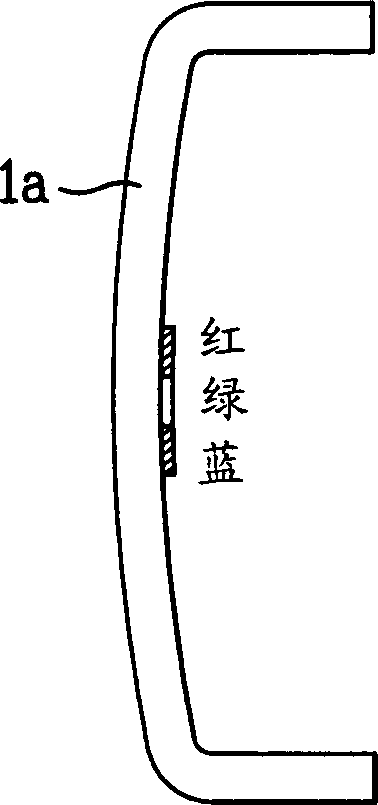

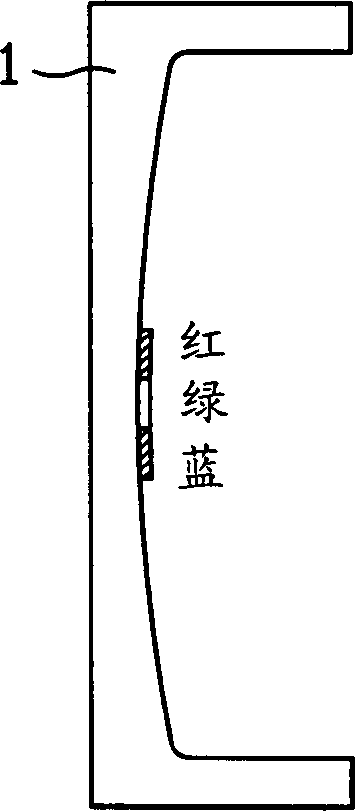

[0035] The wedge of the planar panel in Figure 2B, ie the ratio of the outer thickness to the center thickness of the panel, is greater than that of the non-planar panel shown in Figure 2A. Especially large CRTs over 29" with a wedge greater than 200% have a higher rate of cracking during heat treatment.

[0036] In order to solve this problem, it may be considered to design only the curvature radius of the inner surface of the panel to be larger. However, although this method reduces the wedge, there is a problem that the surface strength of the shadow mask having a curvature similar to that of the inner surface of the panel becomes weaker. Therefore, it is required to find an optimal panel curvature that can reduce the furnace thermal crack rate without reducing the strength of the shadow mask.

[0037] see Figure 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com