Ink jet for piezoelectric ink jetting head and its making process

The technology of an inkjet device and manufacturing method, which is applied in printing and other directions, can solve the problems of reducing ink efficiency, ink disturbance, and limitation, and achieve the effects of avoiding inaccurate pressing alignment, shortening process time, and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

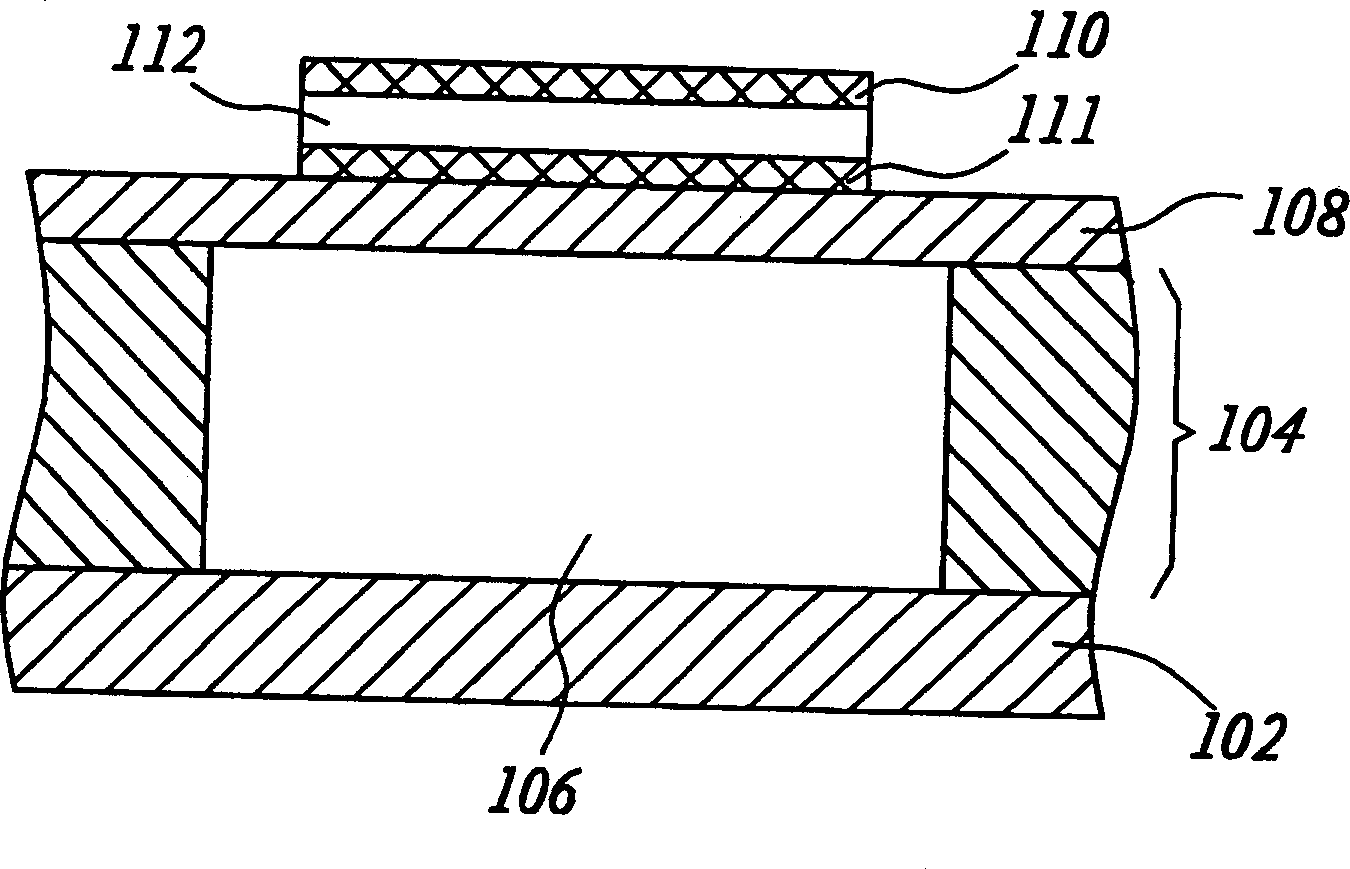

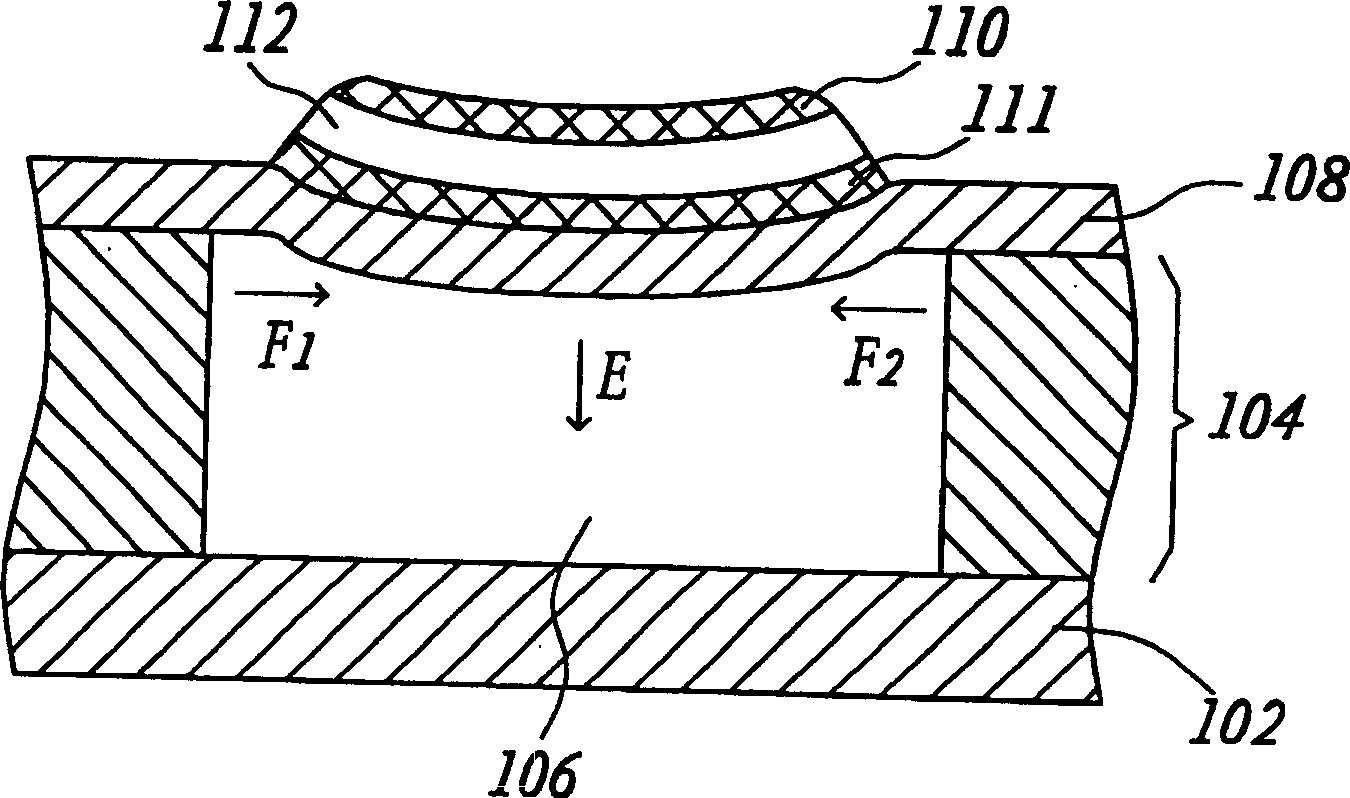

[0024] The technical feature of the present invention is that an ink cavity is defined on a base material, and a metal sheet is used as a vibrating layer of a piezoelectric inkjet head. Wherein, the material of the substrate may be a silicon wafer, a ceramic substrate, or a metal sheet. The metal sheet forms a metal vibration layer on the substrate by means of electroforming, physical vapor deposition (Physical Vapor Deposition, PVD), or chemical vapor deposition (Chemical Vapor Deposition, CVD).

[0025] In this preferred embodiment, a silicon wafer is used as a substrate to describe the manufacturing process of the piezoelectric inkjet head of the present invention, but the present invention is not limited thereby.

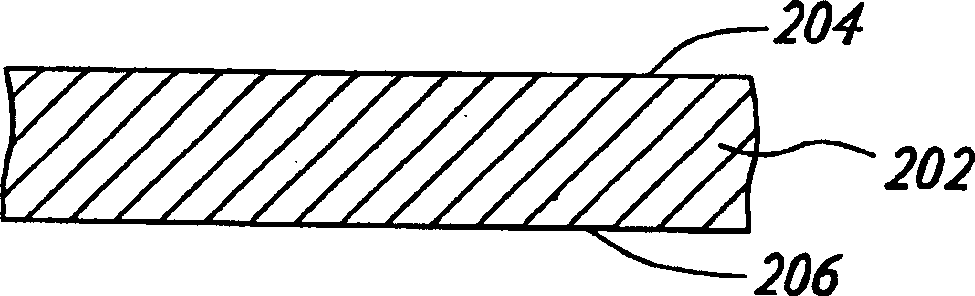

[0026] Please refer to Figure 2A-Figure 2F , which represents a part of the manufacturing process of the inkjet device of the piezoelectric inkjet head according to a preferred embodiment of the present invention. First, a silicon wafer 202 is provided as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com