Diagnosing method for service life of semiconductor manufacturing apparatus

A technology for manufacturing devices and diagnostic methods, applied in semiconductor/solid-state device manufacturing, pump control, general control systems, etc., and can solve problems such as reduced operating efficiency, defective products, and increased maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

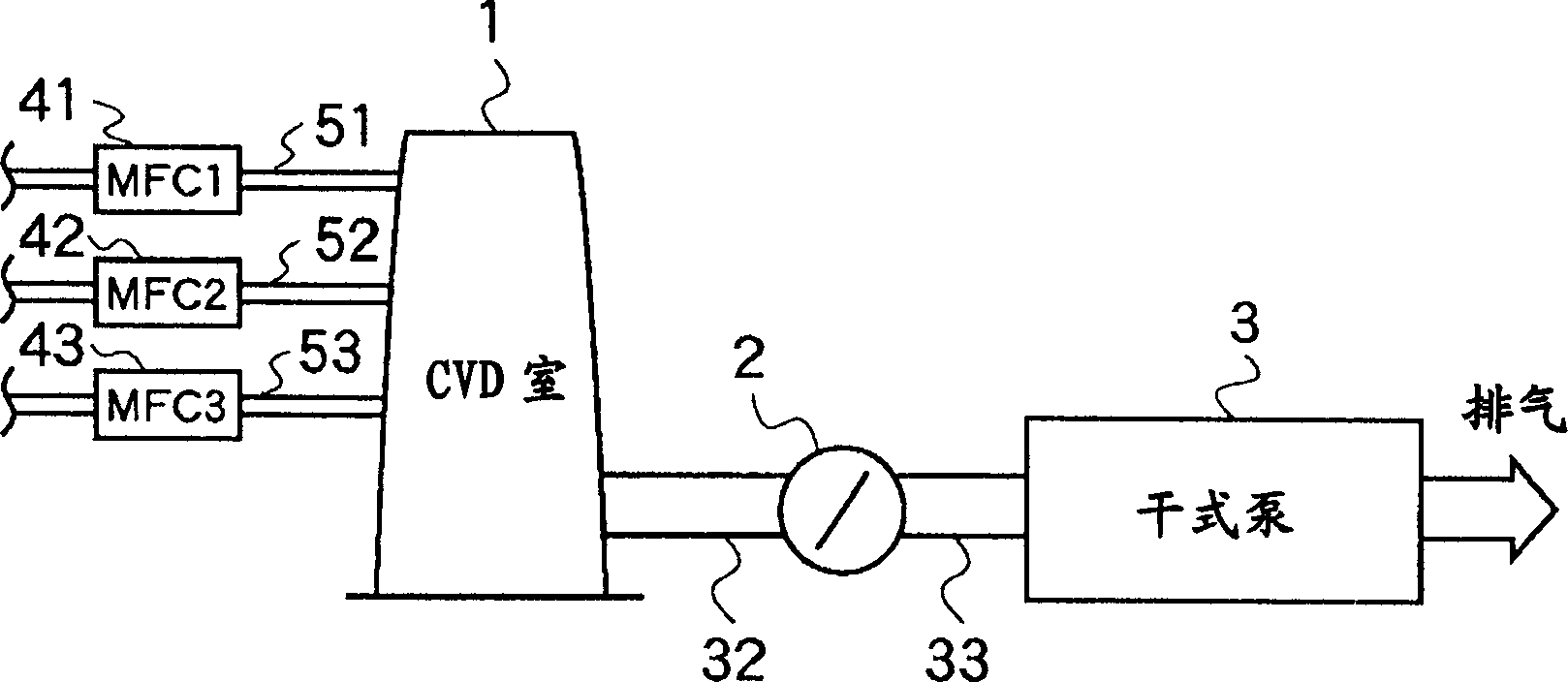

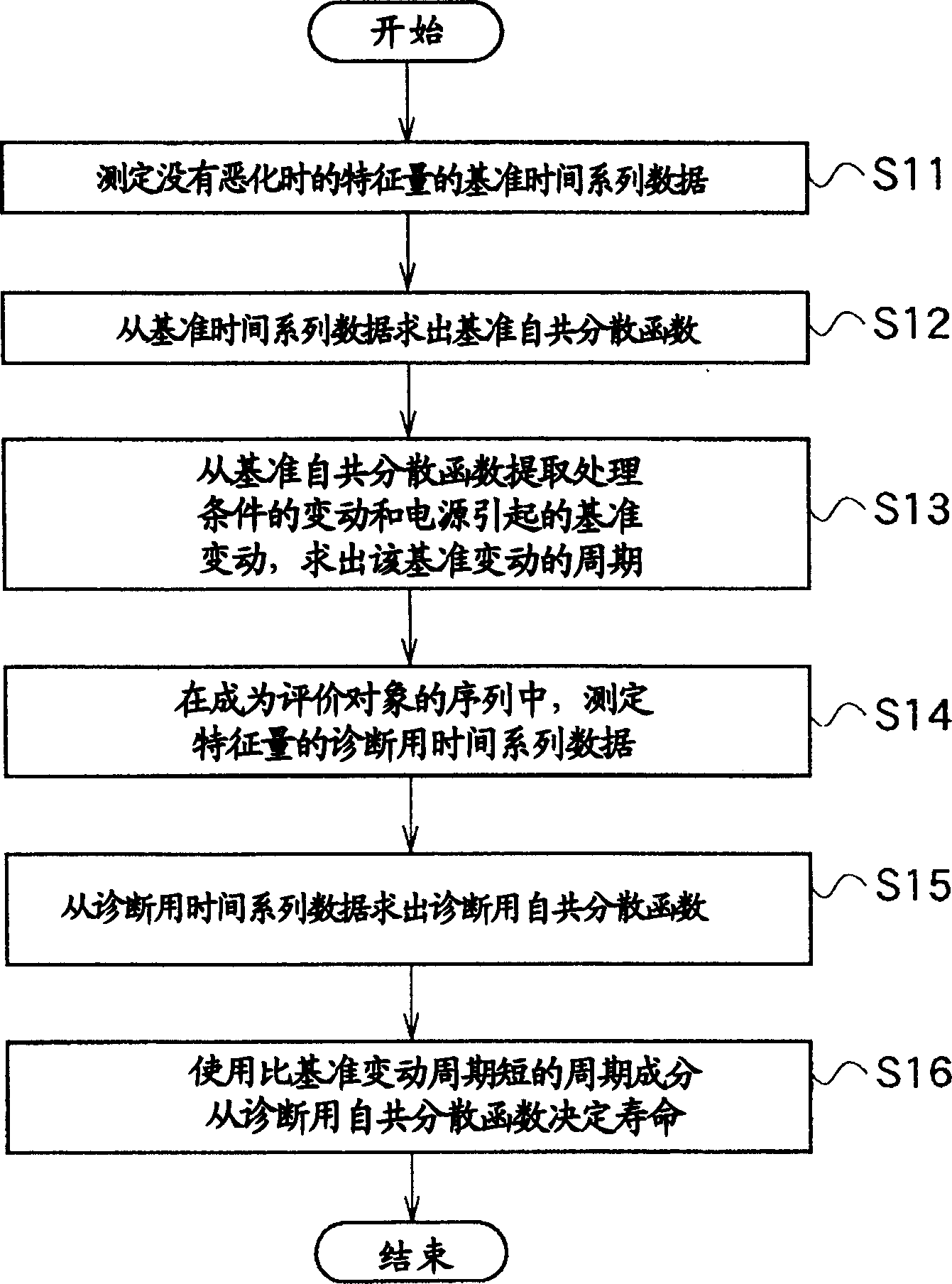

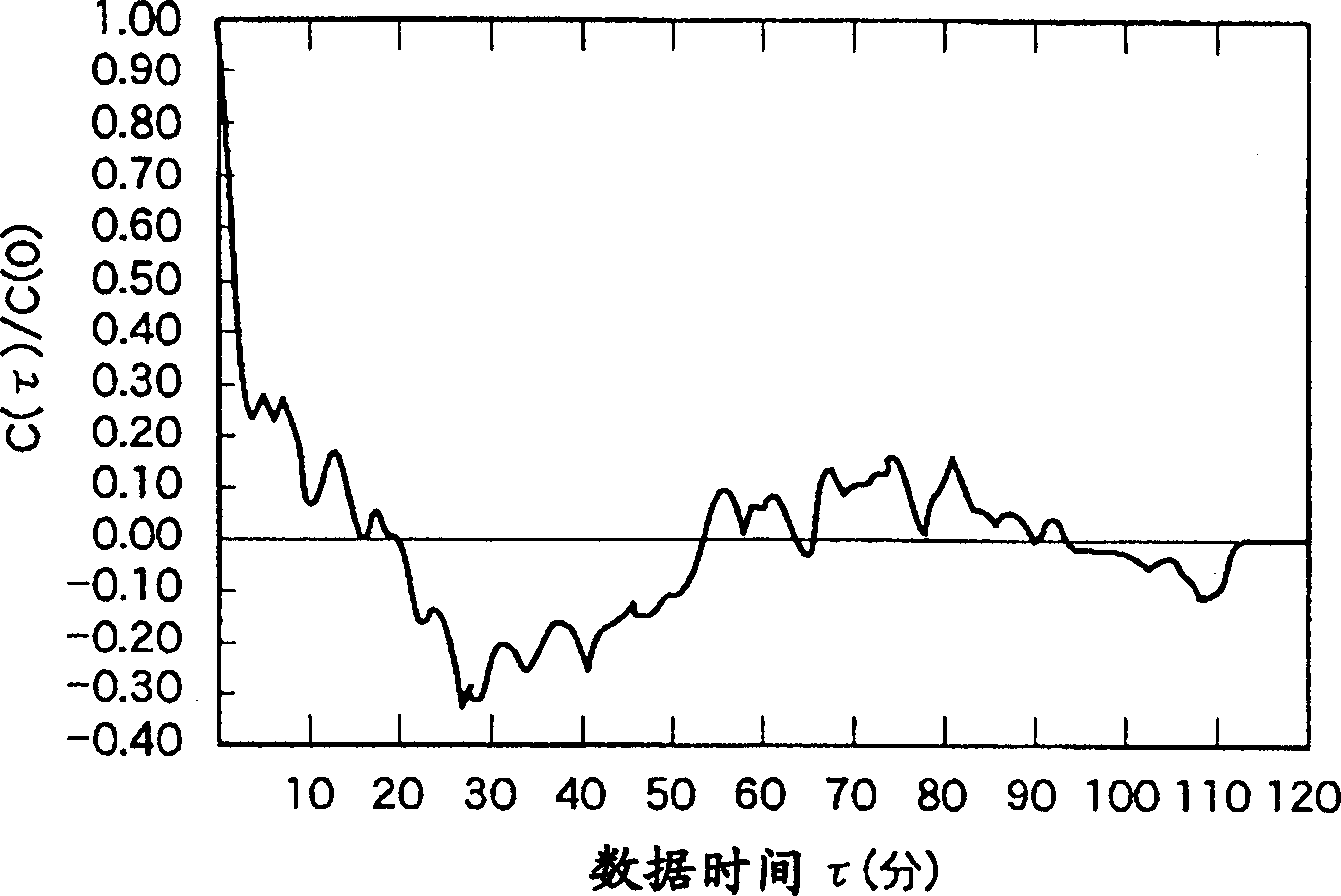

[0030] In the method for diagnosing the lifetime of semiconductor manufacturing equipment according to the first embodiment of the present invention, the time-series data of characteristic quantities such as motor current, motor power, pressure inside the pump, vibration, and gas temperature obtained from the semiconductor manufacturing equipment are analyzed to predict A probabilistic approach to future failures of semiconductor manufacturing equipment. For example, it can be observed that "the motor current of the dry pump increases at a certain moment, and the motor current increases after a specific hysteresis width (data interval) τ", which is helpful for the fault diagnosis of the dry pump.

[0031] First, in order to analyze time-series data of feature quantities acquired from semiconductor manufacturing equipment, it is necessary to assume constancy. Invariance simply means that the time series data at each time is realized by the same probability process, or the stati...

no. 2 example

[0057] The life diagnosis method of semiconductor manufacturing equipment according to the second embodiment of the present invention describes an example of using frequency analysis for failure diagnosis of a dry pump. That is, instead of the motor current self-co-dispersion function C(τ) used in the dry pump failure diagnosis of the first embodiment, the frequency distribution of the casing vibration of the dry pump is analyzed.

[0058] The lifetime diagnosis method of a semiconductor manufacturing device according to the second embodiment of the present invention is based on Figure 7 The procedure shown proceeds:

[0059] (1) First, in step S21, time-series data of a characteristic quantity (vibration) of a dry pump as a semiconductor manufacturing apparatus is measured. Vibration measurement is carried out by measuring the acceleration of the housing with an acceleration sensor every 10 seconds. Each measurement was performed at intervals of 0.5 msec for a total of 1 s...

no. 3 example

[0066] The lifetime diagnosis method of a semiconductor manufacturing apparatus according to the third embodiment of the present invention describes an example of using the Mahalanobis distance MD for failure diagnosis of a dry pump. That is, instead of evaluating the transition of the self-co-dispersion function C(τ) of the motor current used in the fault diagnosis of the dry pump according to the first embodiment, characteristic quantities such as the motor current, the pressure inside the pump, and the vibration of the outer wall of the pump are used to generate The Mahalanobis distance MD.

[0067] A lifetime diagnosis method of a semiconductor manufacturing device according to a third embodiment of the present invention is based on Figure 9 The procedure shown proceeds:

[0068] (1) First, in step S31, the reference time of the corresponding feature quantity is measured under the same processing conditions as the target diagnosis at a predetermined time before the time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com