Vacuum Roots pump set and its control method

A Roots pump and unit technology, applied in pump components, mechanical equipment, machines/engines, etc., can solve the problems of motor power grid shock, power grid overload and power failure, power grid voltage fluctuation, etc., to achieve completely smooth operation, reduce workload, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

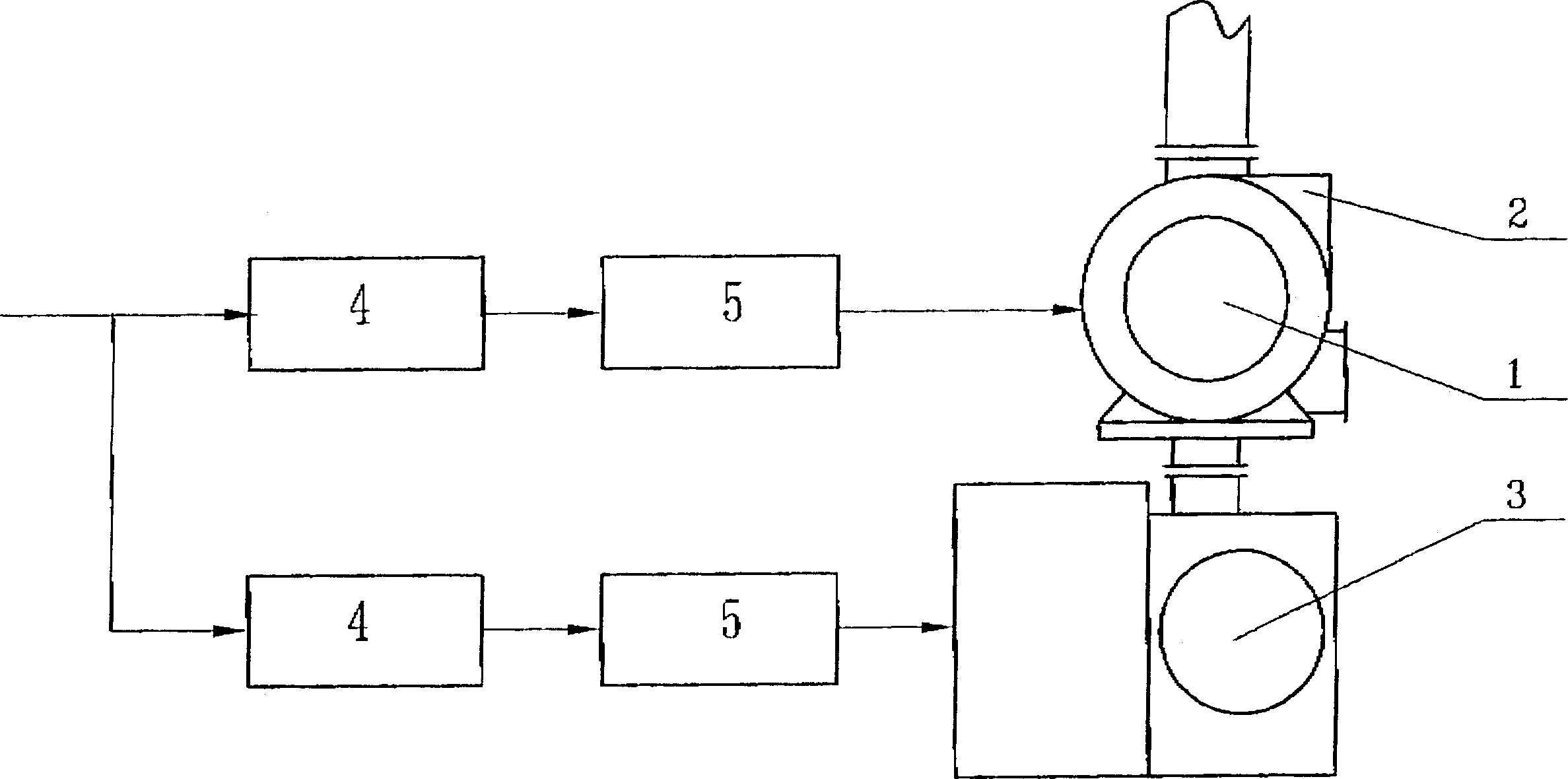

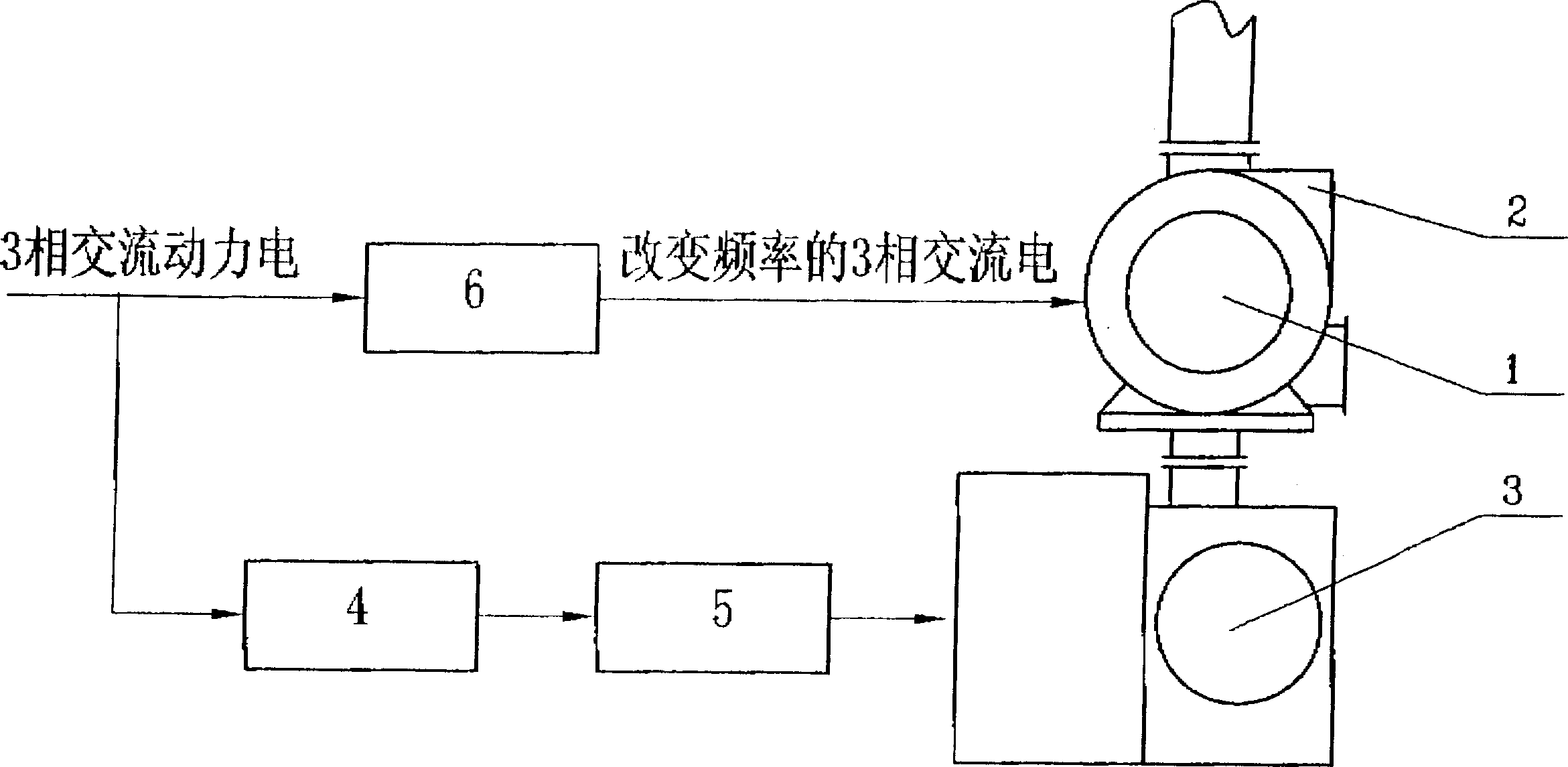

[0020] The vacuum Roots pump unit designed by the present invention, such as figure 2 As shown, it includes Roots pump 1, rotary vane mechanical pump 3, AC contactor 4, and current overcurrent protector 5. Roots pump 1 and rotary vane mechanical pump 3 are connected through pipelines, and AC contactor 4 and current overcurrent The protector 5 is connected with the rotary vane mechanical pump 3 in sequence. The unit also includes a frequency converter 6, which is connected to the motor of the Roots pump 1, and the motor of the Roots pump is controlled by the frequency converter.

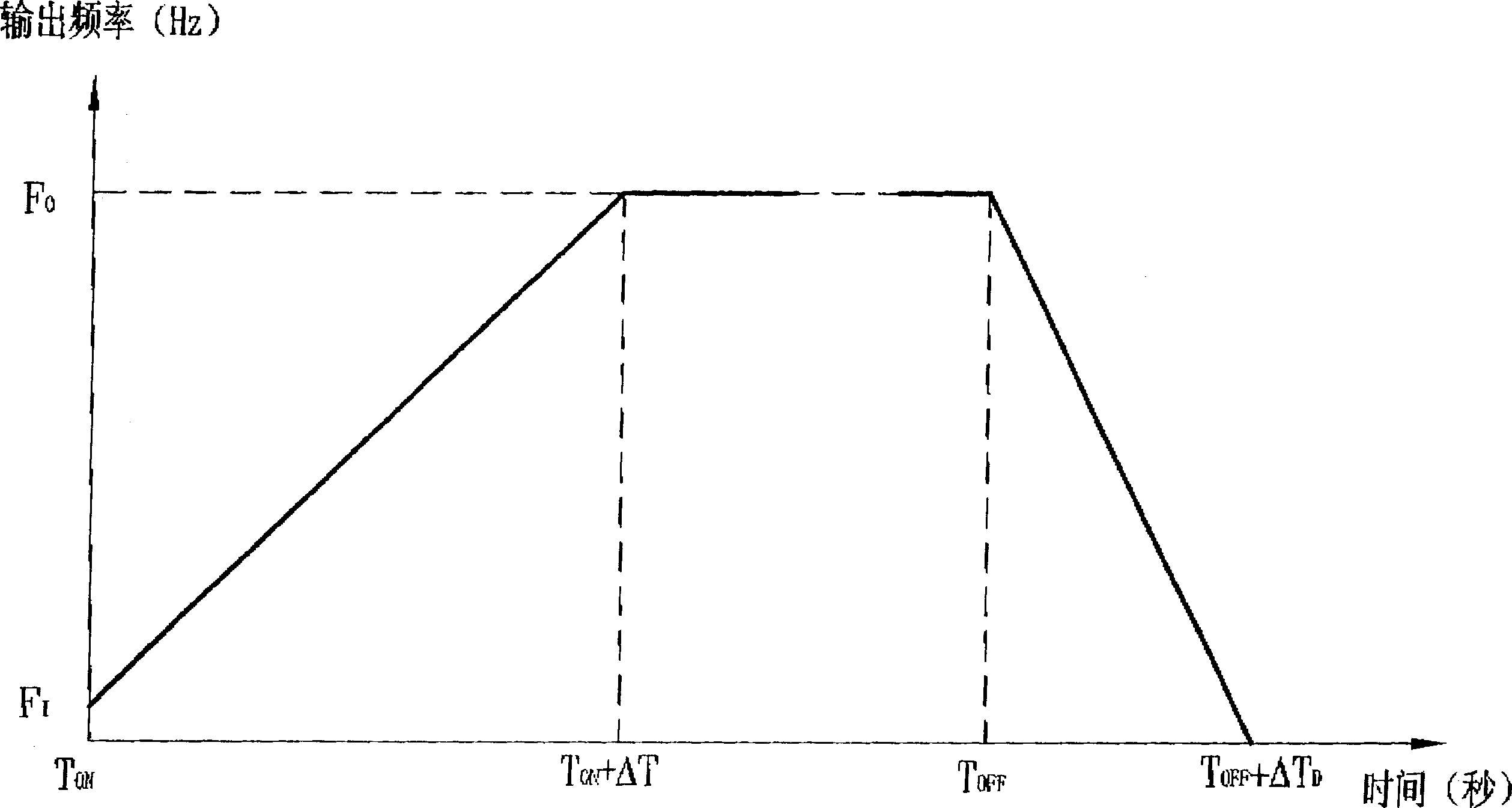

[0021] The control method of the vacuum Roots pump unit proposed by the present invention is to control the output frequency of the frequency converter, and then control the rotating speed of the Roots pump motor. The minimum time required for the vacuum degree of the vacuum system to go from the atmosphere to the vacuum degree of 10Pa × (1±50%).

[0022] It takes 20 seconds to 180 seconds for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com