Flexible printing circuit board adhesive

A technology of adhesives and compositions, applied in the direction of adhesive types, adhesives, epoxy resins, etc., can solve problems such as poor applicability of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Preparation of Solution I

[0036] A-1 50g

[0037] A-2 50g

[0038] C 100g

[0039] D 20g

[0040] Methyl ethyl acetone (MEK) 210g,

[0041] After mixing, grind with a grinder for four hours.

[0042] Step 2: Preparation of Solution II (Hardening Accelerator)

[0043] B-1 2g

[0044] Methyl ethyl acetone (MEK) 12g

[0045] Step 3: Mix the formulation I and the formulation II at a weight ratio of 1:1, and then grind with a grinder for one hour. Obtain a binder solution of 50% by weight.

Embodiment 2

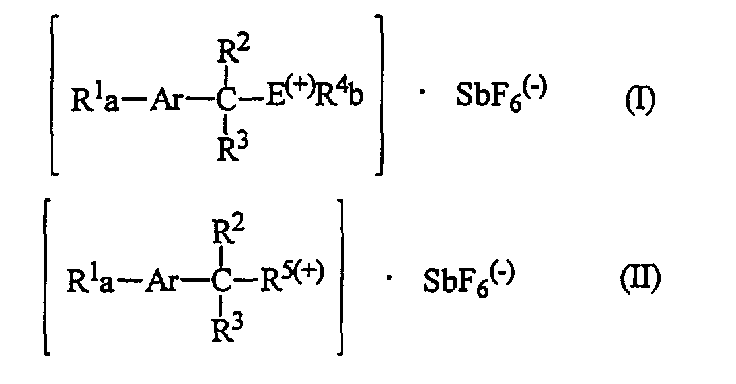

[0047] The step of preparing adhesive is identical with example 1, but changes the hardening accelerator in the dosing II into 2g of hexafluoroantimonic acid (tetra-methoxybenzyl) (one-naphthylmethyl) sulfonium salt (B- 2).

Embodiment 3

[0049] The steps for preparing the adhesive were the same as in Example 1, but the hardening accelerator in the formulation II was changed to 2 g of methyl(tetra-hydroxybenzyl)benzylsulfonium hexafluoroantimonate (B-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com