Method for forming image on disk by ink-jetting style

An optical disc and image technology, which is applied to optical record carriers, optical record carrier manufacturing, and printing of special varieties of printed matter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

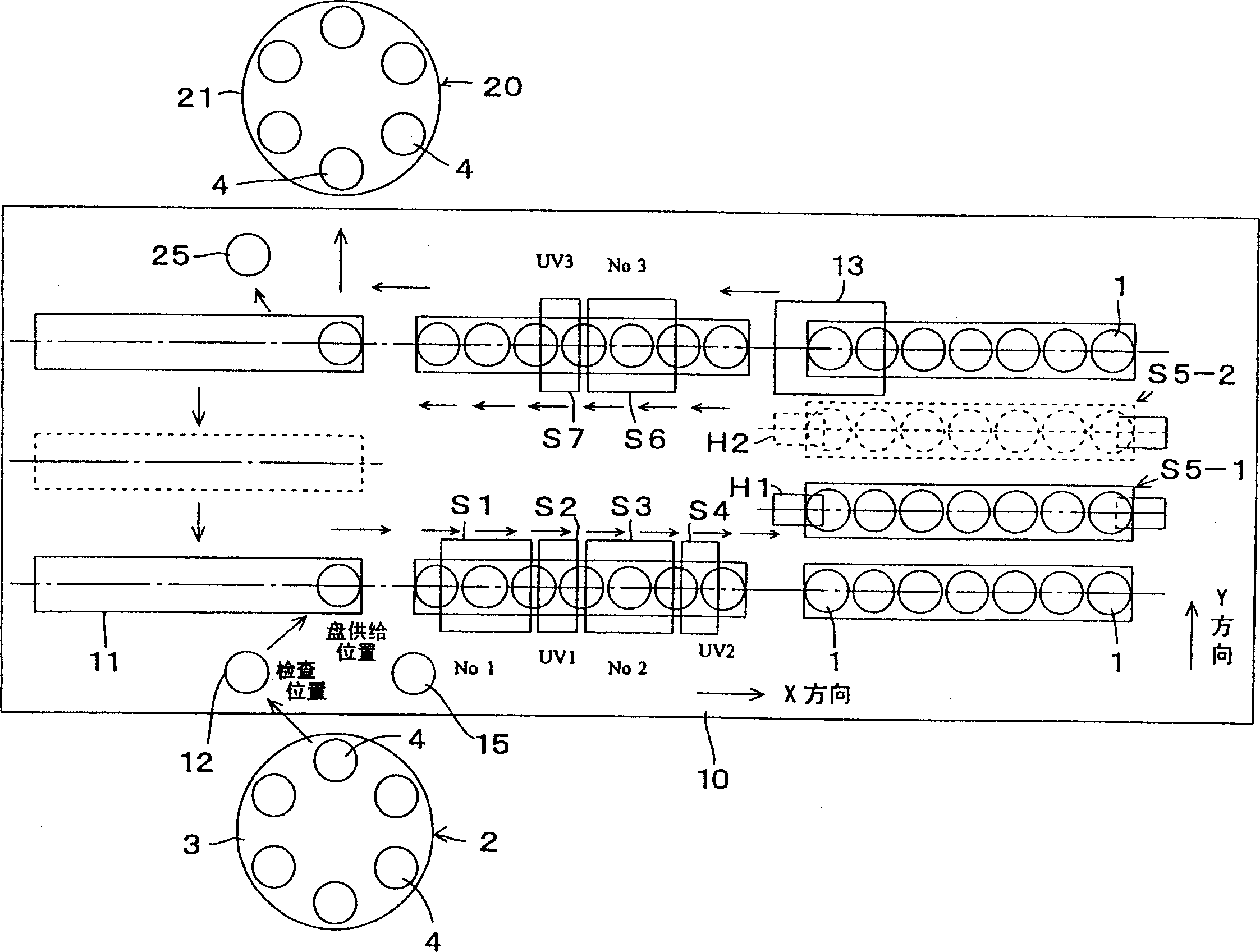

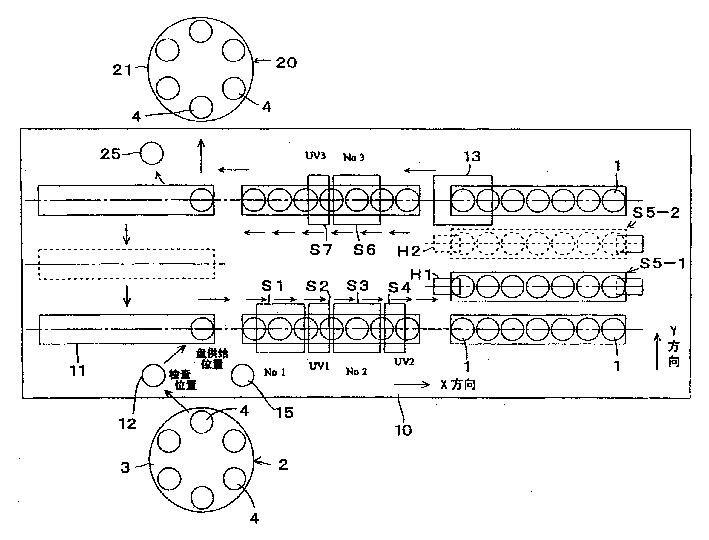

[0030] An embodiment of a method for forming an image on an optical disc by inkjet will be described below with reference to the accompanying drawings.

[0031] figure 1 An embodiment of the method of forming an image on an optical disk by an inkjet method according to the present invention is shown. In this figure, reference numeral 1 represents an optical disc, and reference numeral 2 represents a supply unit for storing a plurality of optical discs. The supply unit 2 includes a stacking platform (turntable) 3 that rotates intermittently at equiangular intervals. 3, place a plurality of rods 4 stacked with multiple optical discs 1.

[0032] On the base 10 of the main body of the apparatus, a plurality of disc transfer trays 11 on which a plurality of optical discs 1 are placed in a linear arrangement are provided so as to be linearly movable (movable along paths in the X direction and the Y direction). Each tray 11 holds the placed optical disc 1 by vacuum suction. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com