Seafood flavouring and its producing method

A production method and seasoning technology, applied in the field of seafood seasoning and its production, can solve problems such as environmental pollution, long production cycle, complex process, etc., and achieve the effects of solving environmental pollution problems, shortening the production cycle, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

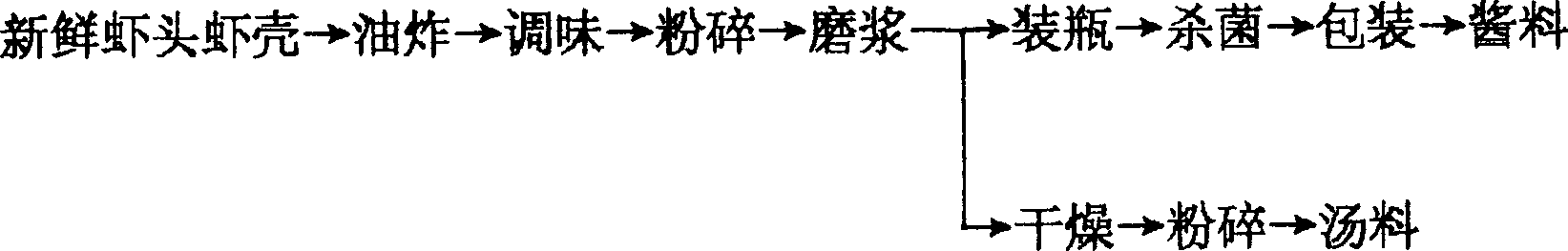

Image

Examples

specific Embodiment approach : Embodiment 1

[0034] The specific implementation method: embodiment one: according to the following production steps:

[0035] ①. Clean the fresh prawn heads and shells, remove other debris, and drain for later use;

[0036] ②. Vacuum fry the drained shrimp heads and shells at an oil temperature of 150-170°C for 2 minutes;

[0037] ③, according to the following formula deployment (%)

[0038] Fresh shrimp head shrimp shell 27.21 IMP 0.02

[0039] Salt 16.41 I+G 0.02

[0040] Chili powder 2.29 Peanut oil 11.66

[0041] Sugar 17.14 Vinegar 1.2

[0042] Garlic 11.43 Onions 2.5

[0043] Ginger 1.14 Bean paste 2.25

[0044] MSG 1.43 Rice wine 0.2

[0045] Sesame oil 0.1 Light soy sauce 5

[0046] ④. The raw materials prepared in the above steps are pulverized once with a pulverizer, and the degree of pulverization is preferably 40 mesh, and then grinded with a grinding wheel for 3 times to obtain a semi-finished product;

[0047] 5., bagging or bottling t...

Embodiment 2

[0049] Steps 1., 2., 3. and 4. are as in Example 1 in the production method to obtain a semi-finished product. After the semi-finished product is dried to a moisture content of 10-15%, it is pulverized to 300 orders to become soup stock, and the finished product is obtained after packaging and sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com