Method for preventing elemental sulfur from adhering to surface of electrode in electrocatalytic reduction process of sulfur dioxide

A technology of sulfur dioxide and electrode surface, applied in electrolysis process, electrodes, electrolysis components, etc., can solve the problems of low catalytic efficiency, reduce energy consumption, adhesion, etc., achieve high reaction efficiency, solve environmental pollution problems, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

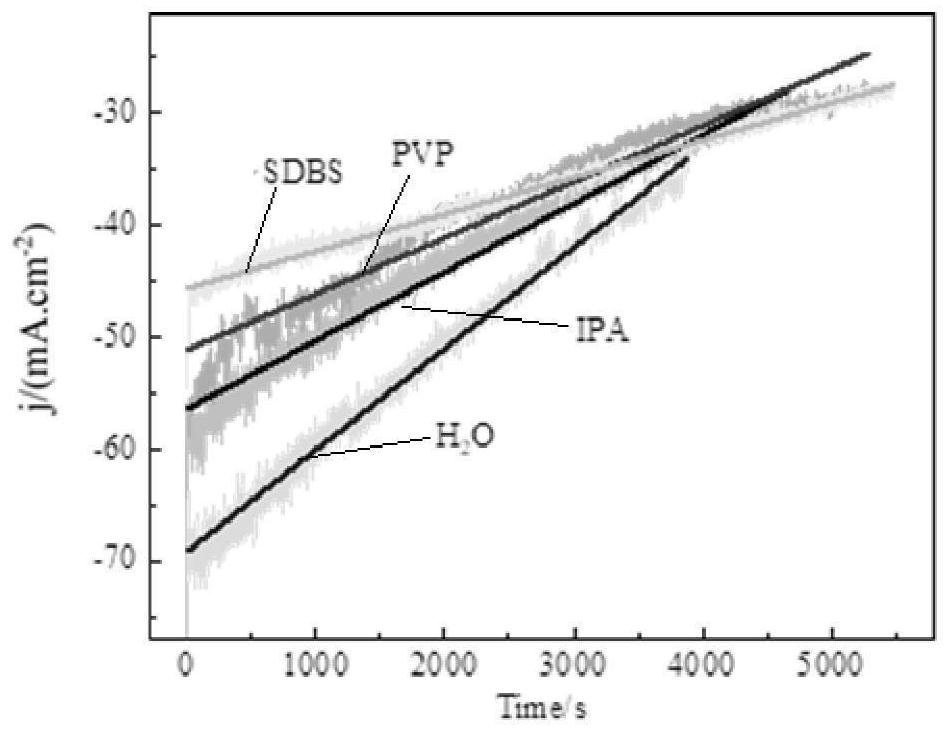

[0031] Analytical pure sodium sulfite, without surfactants.

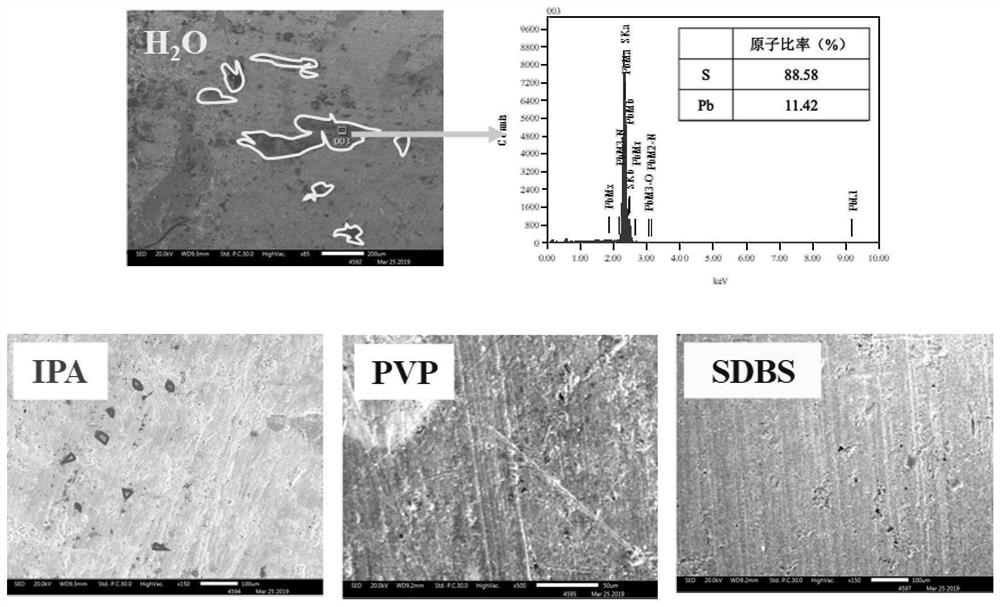

[0032] Mix 50mL of water and sodium sulfite (0.08mol / L) in a certain ratio evenly and take it into the cathode chamber as catholyte, 50mL of anhydrous sodium sulfate aqueous solution as anolyte, lead sheet as working electrode, and Pt as counter electrode. electrode, and SCE as a reference electrode. Perform electrochemical performance tests. Select -0.8V electrolysis potential in the process, control the same electrolysis power (400C), sulfite concentration is 0.08mol / L, use sulfuric acid to adjust the pH of the cathode and anode electrolysis chamber to 0.5, stir at 1000rmp, test the current density-time curve (i-t curve). The slope of the i-t curve is 0.09.

Embodiment 2

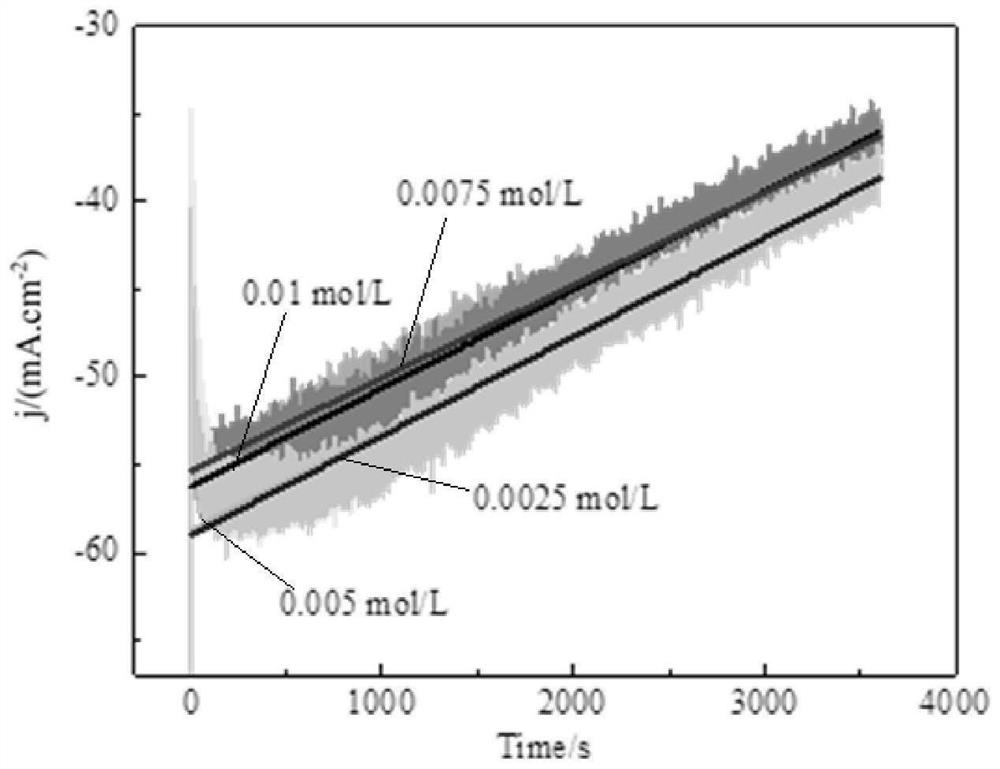

[0034] Mix 50mL of water, sodium sulfite (0.08mol / L) and 5% isopropanol solution (0.01mol / L) in a certain ratio evenly and take it into the cathode chamber as catholyte, and 50mL of anhydrous sodium sulfate solution as anode Electrolyte, lead sheet as working electrode, Pt as counter electrode, SCE as reference electrode for electrochemical performance test. Select -0.8V electrolysis potential in the process, control the same electrolysis power (400C), sulfite concentration is 0.08mol / L, use sulfuric acid to adjust the pH of the cathode and anode electrolysis chamber to 0.5, stir at 1000rmp, test the current density-time curve (i-t curve). The i-t curve slope can be reduced from 0.09 to 0.06.

Embodiment 3

[0036] Mix 50mL of water, sodium sulfite (0.08mol / L), and 0.3g / L polyvinylpyrrolidone (PVP) in a certain proportion and take them into the cathode chamber as catholyte, and 50mL of anhydrous sodium sulfate as anolyte , the lead sheet was used as the working electrode, Pt was used as the counter electrode, and SCE was used as the reference electrode for electrochemical performance testing. Select -0.8V electrolysis potential in the process, control the same electrolysis power (400C), sulfite concentration is 0.08mol / L, use sulfuric acid to adjust the pH of the cathode and anode electrolysis chamber to 0.5, stir at 1000rmp, test the current density-time curve (i-t curve). The i-t curve slope can be reduced from 0.09 to 0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com