Comb shaped antisalt polymer thickening agent

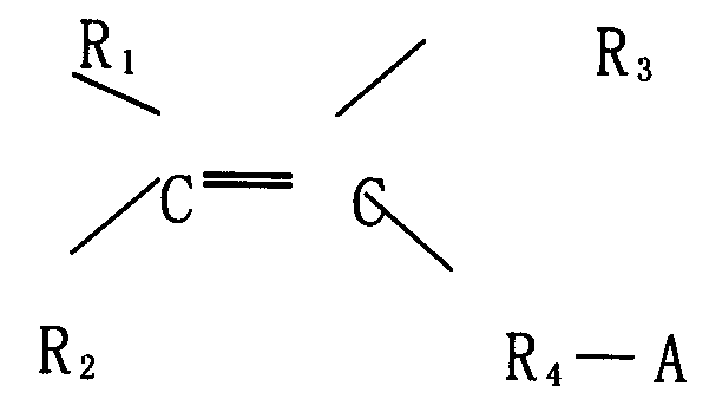

A polymer and thickener technology, applied in drilling equipment, etc., can solve problems such as lack of viscosity, waste of oilfield produced water, low viscosity of polymer solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 125 parts of 10-hydroxydecanoic acid in 150 parts of ethanol, add 50 parts of allyl chloride, heat to reflux and dropwise add a concentrated solution of caustic soda, distill off ethanol and water to obtain the monomer (B) of the present invention.

[0022]Preparation of comb-shaped salt-resistant polymer thickener:

Embodiment 2

[0024] In the water solution containing 15% acrylamide and 5% B monomer, deoxygenate with nitrogen for 30 minutes, add 0.2 azobisisonitrile initiator, and keep the temperature at 60 ° C for 14 hours to obtain a viscoelastic hydrogel product .It can be dried at 100°C for 8 hours through a kneader to obtain a solid product.

Embodiment 3

[0026] In an aqueous solution containing 9% acrylic acid amine, 6% acrylic acid, and 8% B monomer, adjust the pH to 8 with sodium hydroxide, deoxygenate with nitrogen for 30 minutes, add 0.1 ammonium persulfate and 0.1 diabolite, and keep the temperature at 40°C for 8 hours , to obtain viscoelastic hydrogel products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com