Hyperbolic shaped steel bearing for engineering structure

A technology of engineering structures and steel bearings, which is applied to building structures, bridge parts, bridges, etc., to achieve the effects of improving safety and dynamic reliability, preventing the intrusion of sand, dust and rain, and having a strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The hyperbolic steel support for engineering structures of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

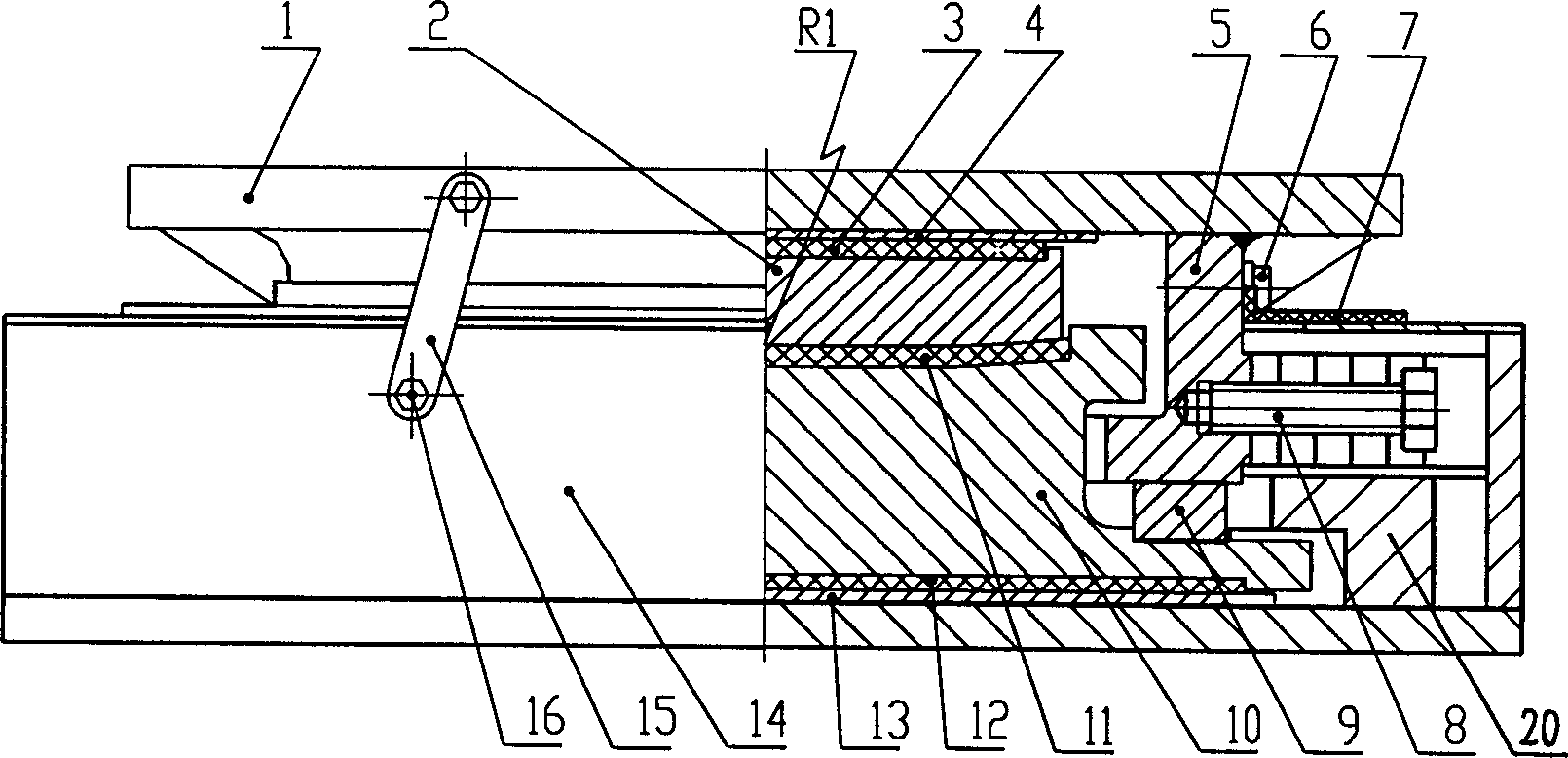

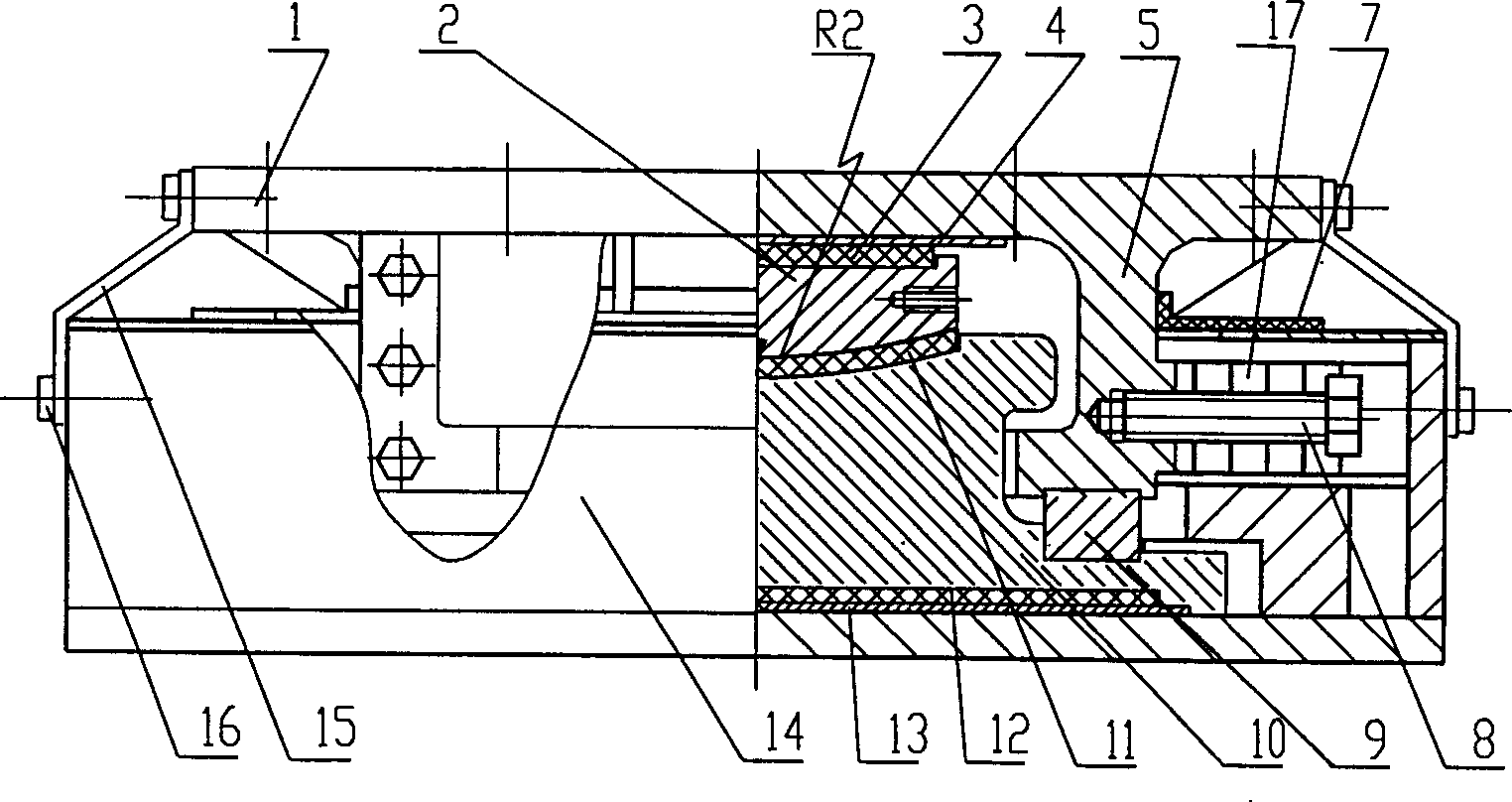

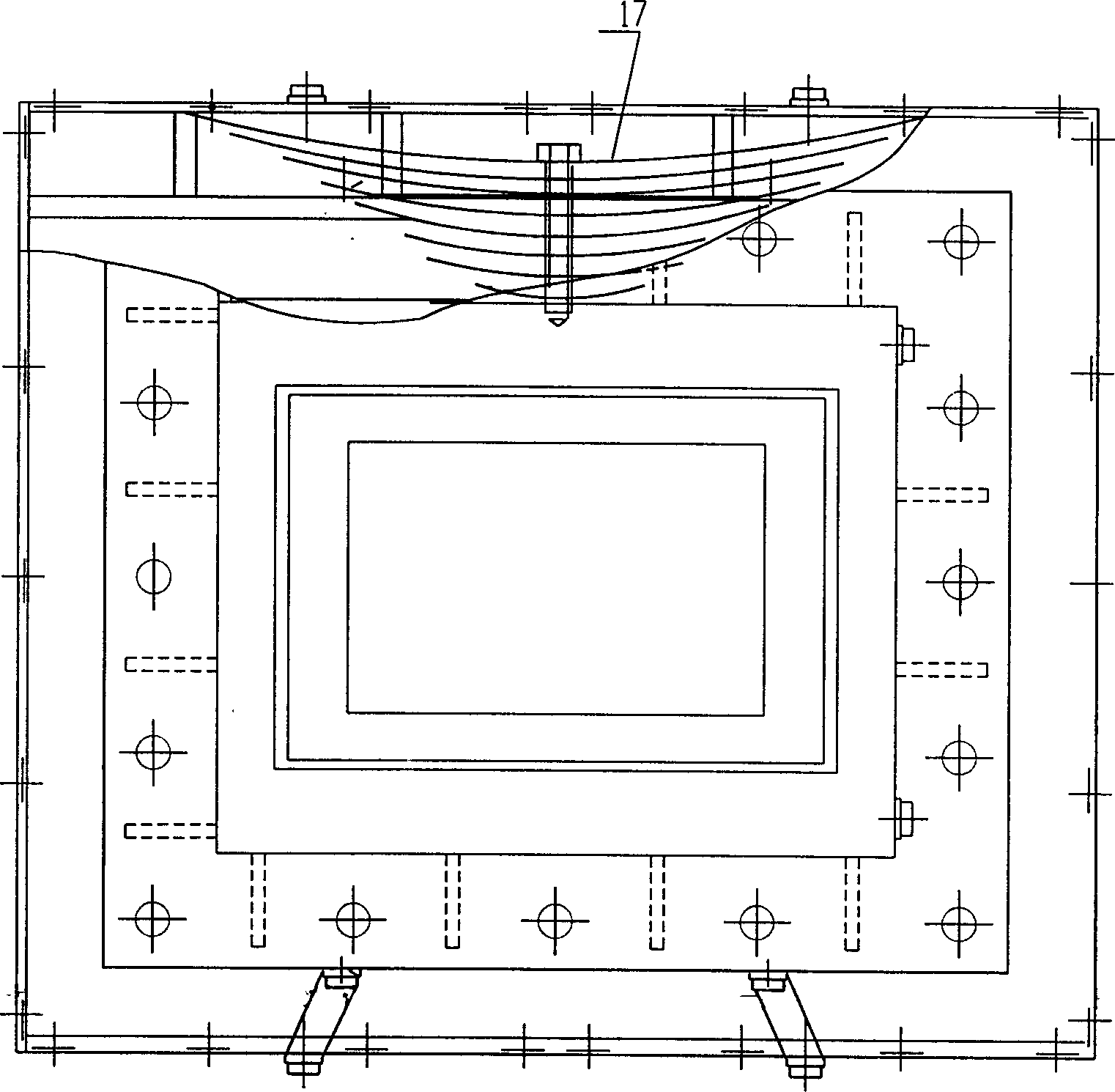

[0024] Such as figure 1 and figure 2 As shown, the hyperbolic steel support used for engineering structures includes an upper cover 1, a central core 2, a base 10 and a fixed box 14. The lower part of the central core 2 is a hyperbolic spherical crown with a radius of curvature of R1. The radius of curvature in the vertical direction is R2, R2<R1, and the center of the upper surface of the base 10 has a hyperbolic concave cavity corresponding to the curvature of the central core, and the hyperbolic lower surface of the central core 2 is located in the concave cavity of the base 10. There is a polytetrafluoroethylene backing plate 11 between the center core and the base to reduce the friction force when the center core rotates in the cavity. The bottom of loam cake 1 has a concave ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com