Super-pure ethanol refining process

An ethanol and ultra-pure technology, which is applied in the preparation of hydroxyl compounds, organic compounds, organic chemistry, etc., can solve the problems of high cost of ultra-pure ethanol rectification, a large number of equipment, and lengthy production processes, etc., to improve the separation ability and The reliability of equipment, the simplicity of process flow, the effect of reducing operating costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

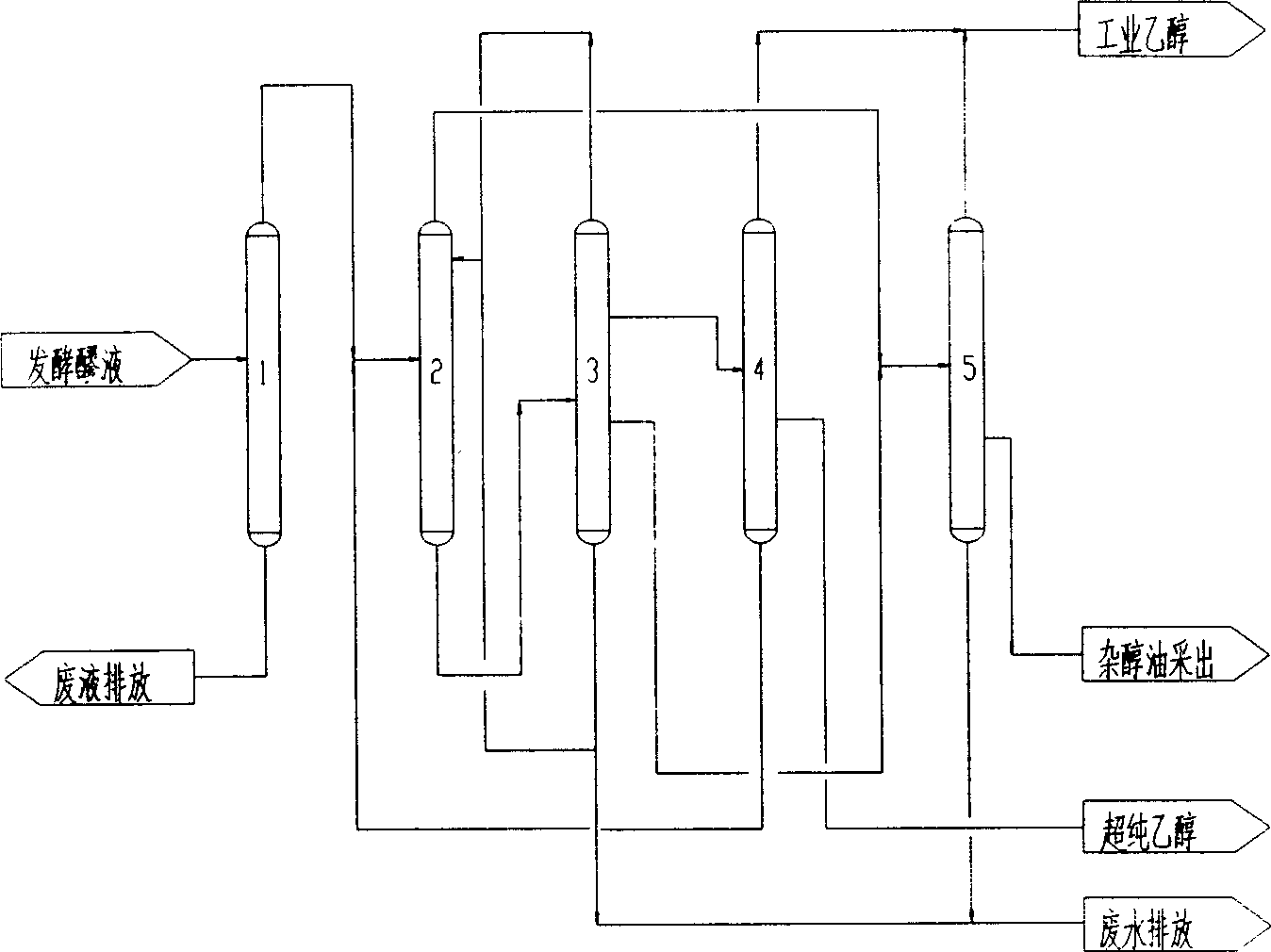

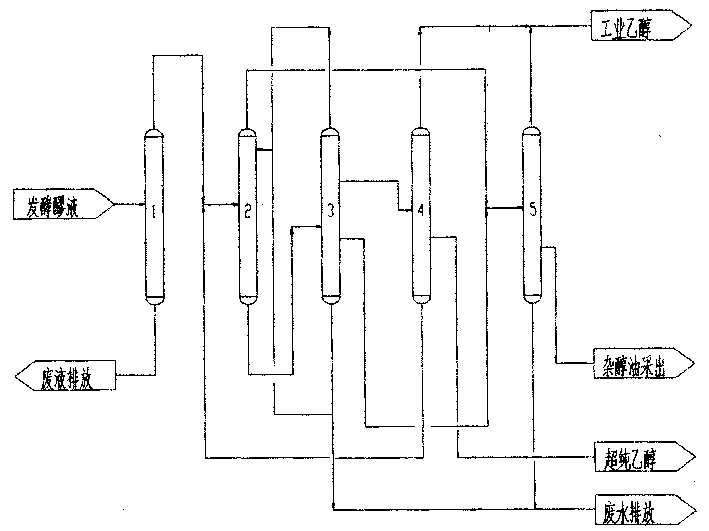

[0014] As shown in the figure, the ultra-pure ethanol refining process is mainly composed of 1-crude distillation tower, 2-dealdehyde tower, 3-refining tower, 4-demethanol tower and 5-recovery tower unit equipment.

[0015] (1) The raw material liquid with an ethanol content of 5-30% enters the crude distillation tower 1. After vapor-liquid mass transfer separation, the waste liquid is discharged from the tower kettle and sent to the outside of the device area for treatment. The ethanol liquid extracted from the top of the tower is sent to the dealdehyde tower 2. The decompression operation pressure of the tower is -0.02~0.08MPa. The main task of the crude distillation tower is to remove most of the water, organic acid and heavy component impurities brought along with the fermentation mash.

[0016] (2) The 30-80% ethanol liquid extracted from the top of the crude distillation tower and the stream from the refining tower kettle are sent to the dealdehyde tower 2, and impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com