Probe card for LCD detection

A probe card and stylus technology, which is applied to coupling devices, measuring device casings, instruments, etc., can solve problems such as complicated operations, thickening of the guide plate 5, and inability to accurately identify the state of the stylus insertion groove 5a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail using the drawings.

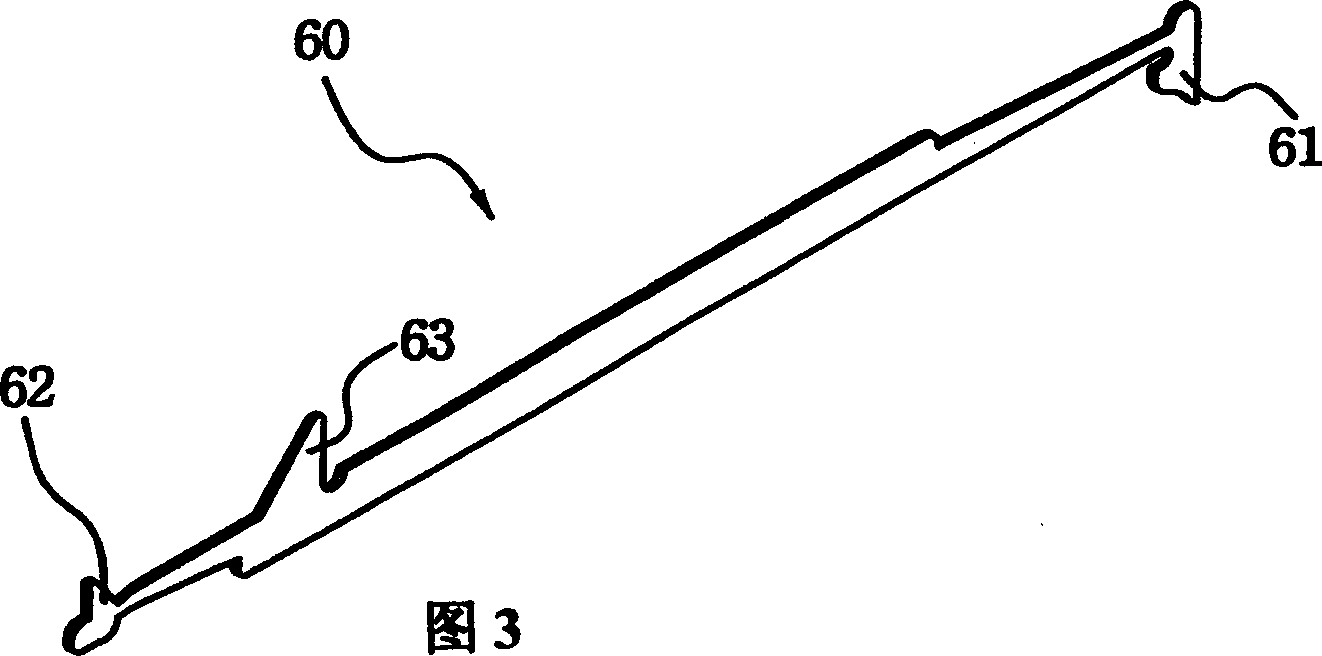

[0035] The present invention is characterized in that the guide plate has a silicon plate of the same material as the known chip, and at the same time it is thinned, and the stylus insertion groove is obtained by patterning in the above silicon plate, and the depth of the stylus insertion groove can be formed. It is possible to check the degree of processing of the stylus insertion groove to the extent that the microscope can identify it, and to prevent deflection and deformation of the connecting ends on both end sides of the stylus plate inserted into the stylus insertion groove.

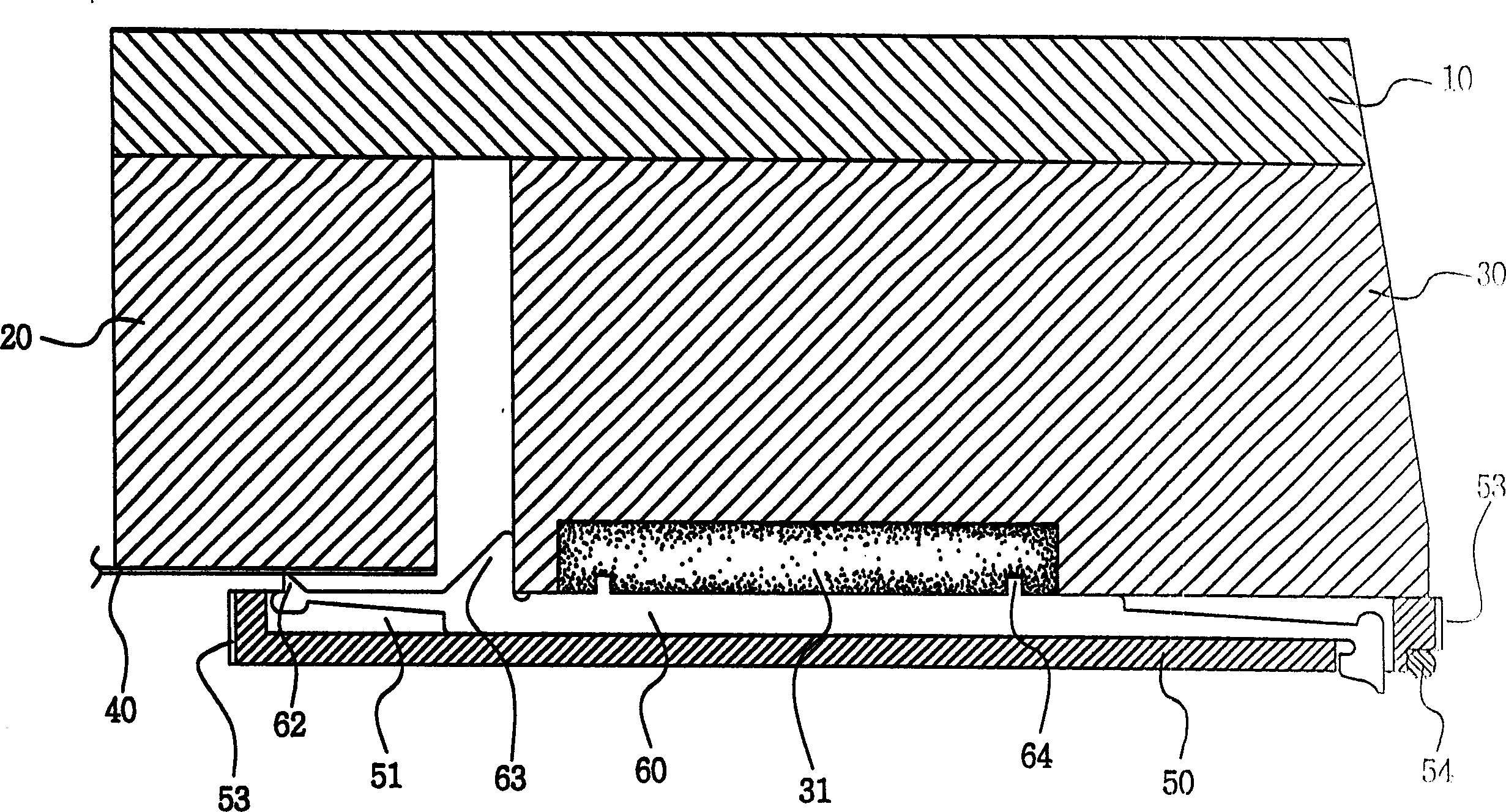

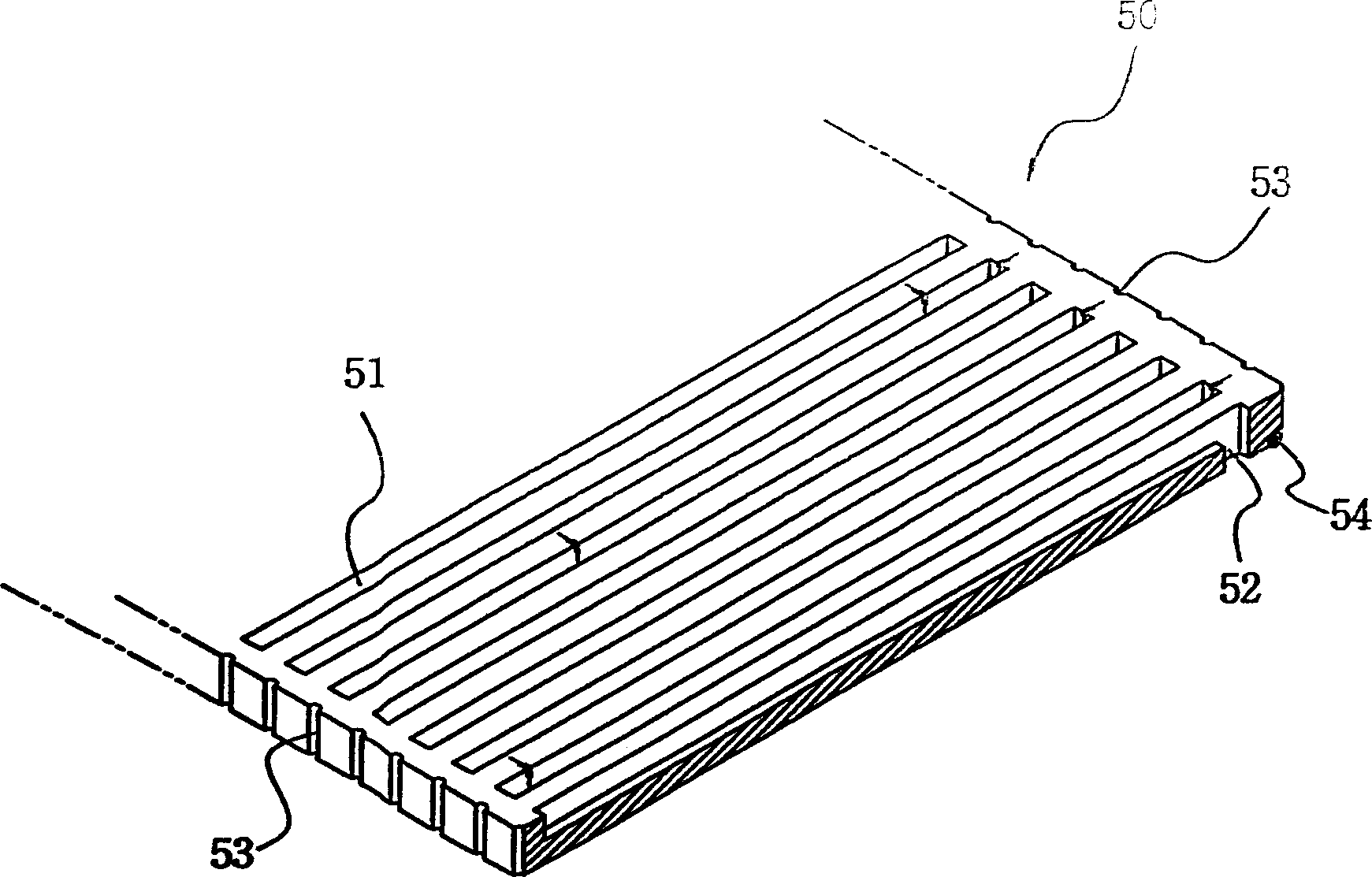

[0036] The present invention as figure 1 As shown, a base plate base 20 is connected and fixed on one side of the assembly base 10 and the bottom surface of the assembly base 10 , and a stylus base 30 is provided on the other side corresponding to the base base 20 to form a structure similar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com