Silent cam

A silent, cam technology, applied in the field of standard parts, can solve the problems of low guiding accuracy, high noise of ordinary cams, short service life, etc., and achieve the effects of high safety, high operating efficiency and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

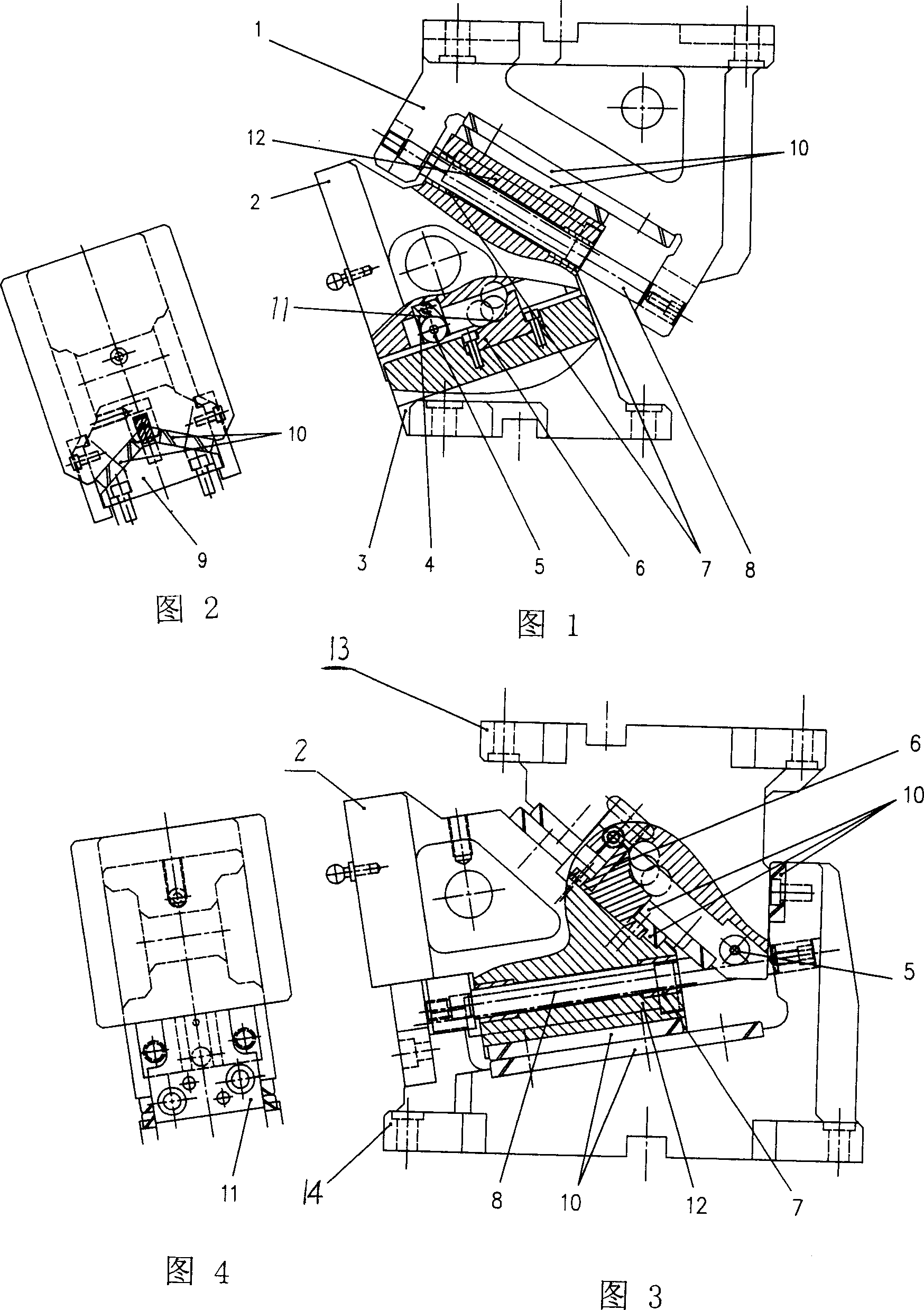

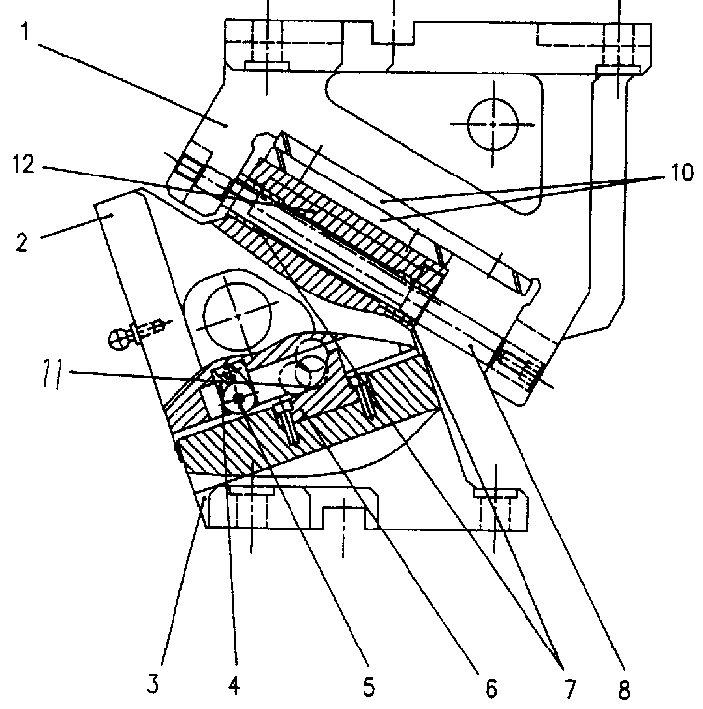

[0023] Embodiment 1 is a suspended silent cam, as shown in Figures 1 and 2, there is a sliding block 2 between the upper base 1 and the lower base 3, the sliding block and the upper base 1 are assembled together, and the sliding block and the base use a guide rod 8 are connected together, the front end of the guide rod is threaded, and the rear end has an inner hexagonal hole, which is convenient for disassembly and assembly. A guide sleeve 7 is installed on the sliding block, which cooperates with the guide rod to realize circular guidance. The fitting gap of the guide rod is very small, only about 0.01mm, so the space between the guide sleeves assembled at both ends of the sliding block is basically sealed, which can effectively prevent debris and other garbage from entering. Sliding block is when return stroke, and return stroke force is provided by nitrogen spring 11 under normal circumstances, if there are special circumstances (nitrogen gas spring is damaged or return str...

Embodiment 2

[0024] Embodiment 2 is a lower-mounted silent cam, as shown in Figures 3 and 4, there is a sliding block 2 between the lower-type upper base 13 and the lower-type lower base 14, and the sliding block and the lower base of the lower-type silent cam are assembled together to slide Block and base are connected together with guide rod 8, and guide rod front end has screw thread, and rear end has hexagon socket hole, is convenient to dismounting. A guide sleeve 7 is assembled on the slide block, and cooperates with the guide rod to realize circumferential guidance. When sliding block is on the return journey, return force is provided by nitrogen spring 11 under normal circumstances, if there are special circumstances (nitrogen spring is damaged or the return resistance is too large when nitrogen spring force is not enough), the forced pull-back block works to make the sliding block return to its original position. The lower type mute cam is equipped with a roller 5 on the upper bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com