Foundation waterproof construction method and waterproof structure

A construction method and foundation technology, which can be used in infrastructure engineering, anti-fouling/underwater coatings, protection devices, etc., can solve problems such as peeling, offset, and weaken the adhesion between the waterproof layer and the asphalt mixture, and achieve good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

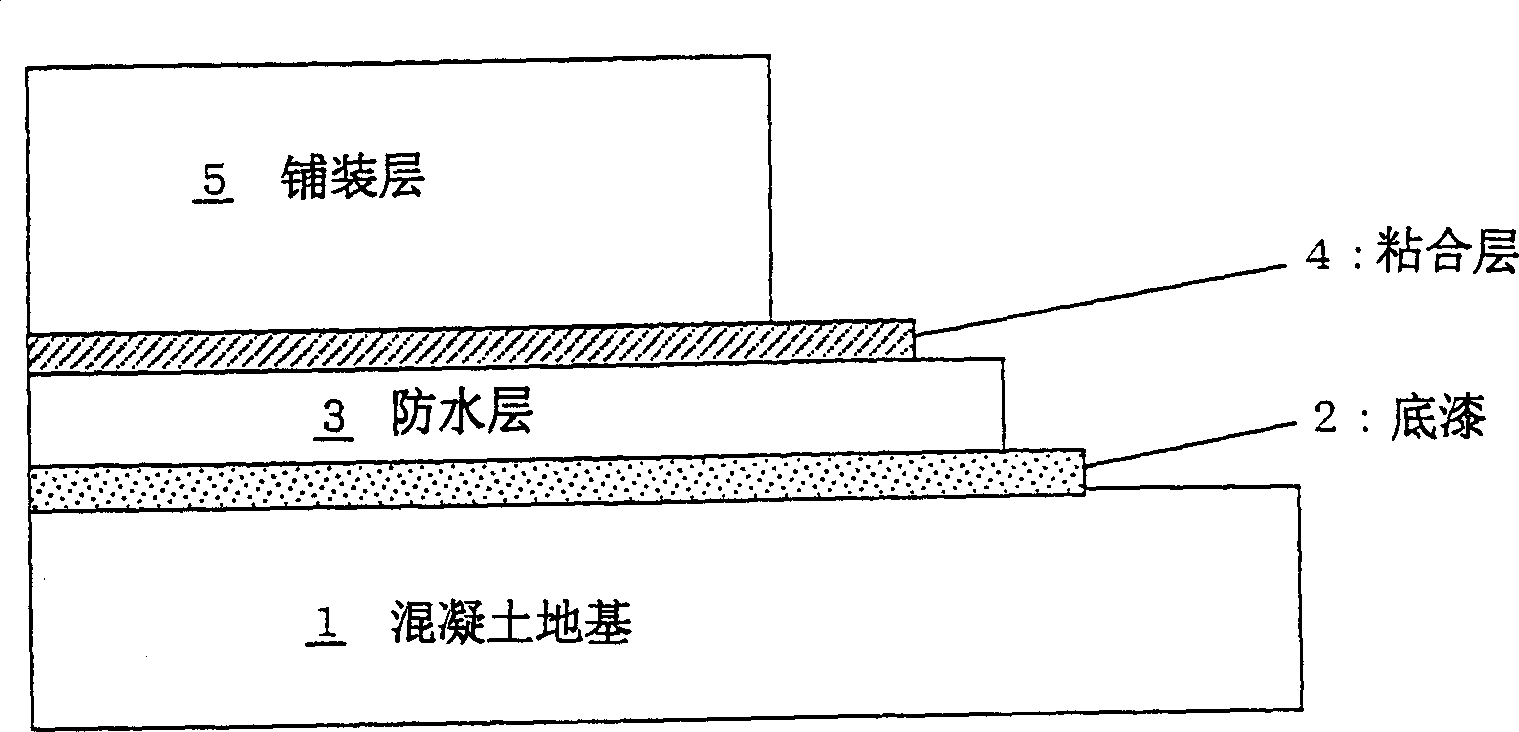

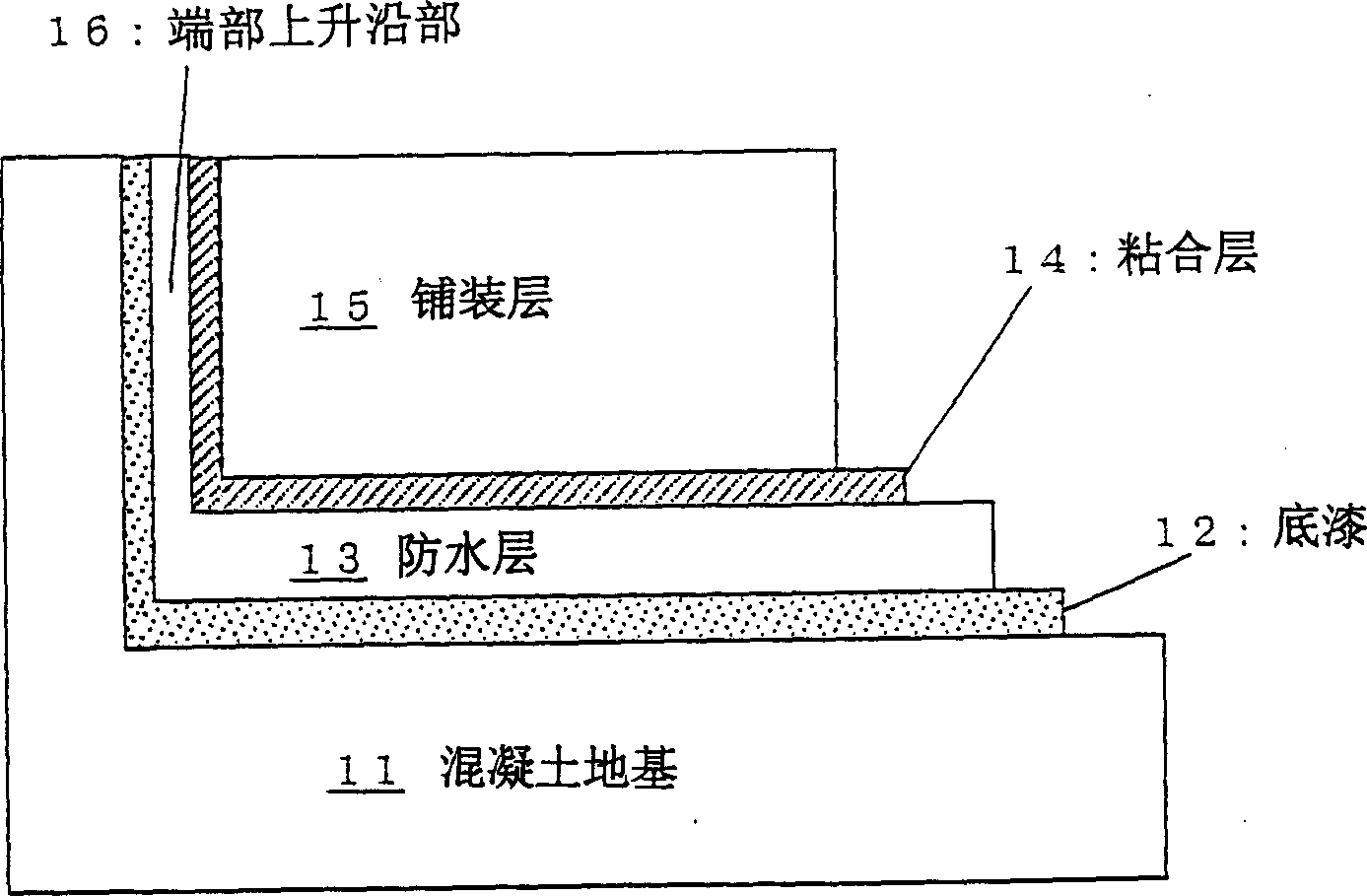

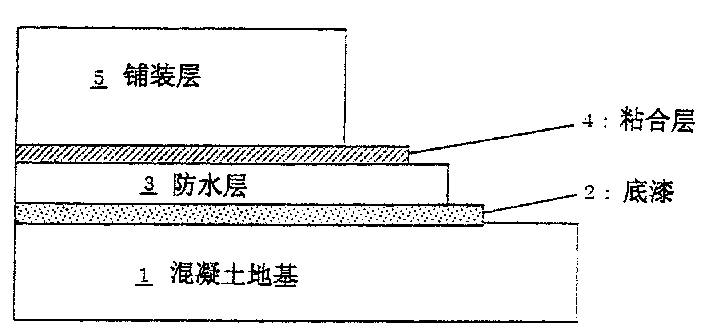

[0045] Examples of the present invention will be specifically described below. First, apply a water-based epoxy resin primer (Tough guard R-W primer, manufactured by Nippon Paint Co., Ltd.) on the foundation concrete, and after the primer dries, apply a two-component curing polyurea resin (two-component polyurea resin) to form a waterproof layer. Component curable resin A) (Tough guard R-G or Tough guard R-M, both manufactured by Nippon Paint Co., Ltd.). Then, apply a two-component curing polyurea resin (two-component curing resin B) (Tough guard R-P, manufactured by Nippon Paint Co., Ltd.) to form an adhesive waterproof layer, and lay it on top to form a pavement before curing. layer of asphalt mixture.

[0046] In the present embodiment, the coating amount of the water-based epoxy resin primer used is 0.04 kilograms per 1 square meter, and the coating amount of the two-component curing type polyurea resin (two-component curing type resin A) used is 1.1 kg (1 mm in thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com