Heat-sealing apparatus for bag-making machine

A heat-sealing device and bag-making machine technology, applied in container manufacturing machinery, envelope/bag manufacturing machinery, packaging, etc., can solve problems such as difficult temperature control, uneven temperature of electric heating tube molds, etc., and achieve good bag making quality and structure Simple, low-cost-to-produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

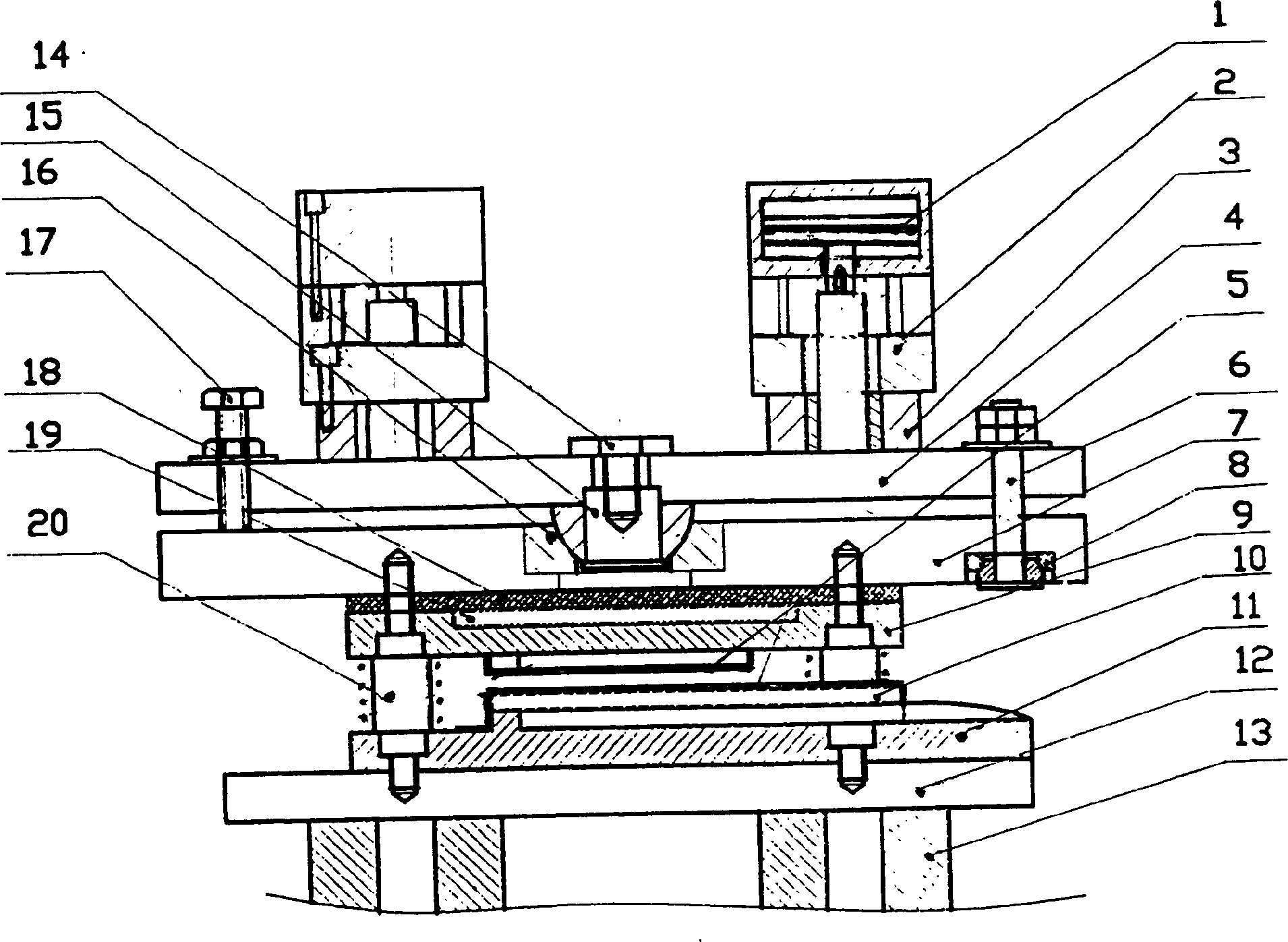

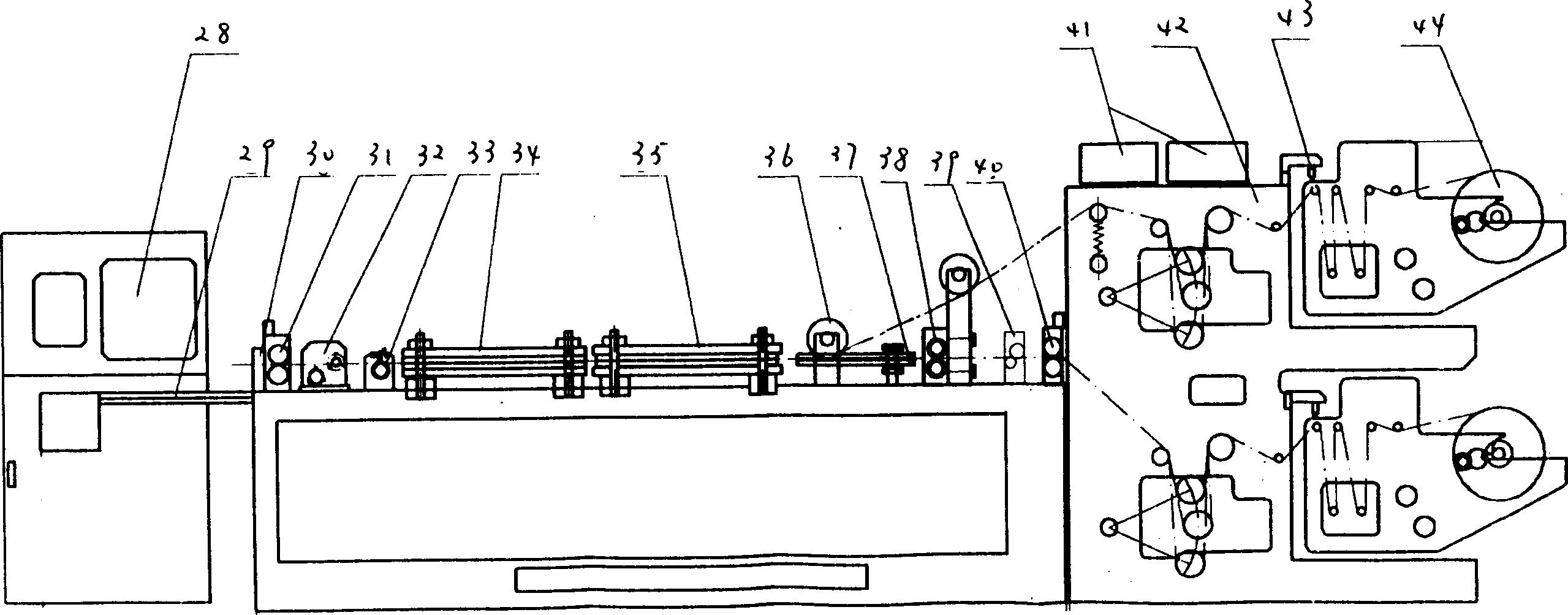

[0014] Such as figure 1 , The invention is a heat sealing device of a bag making machine. Its function is to heat seal the upper and lower layers of film passing through it. It mainly consists of a lower mold assembly, an upper mold assembly, a linkage rod 20 and a pneumatic pressure device (a cylinder) 1 in the figure.

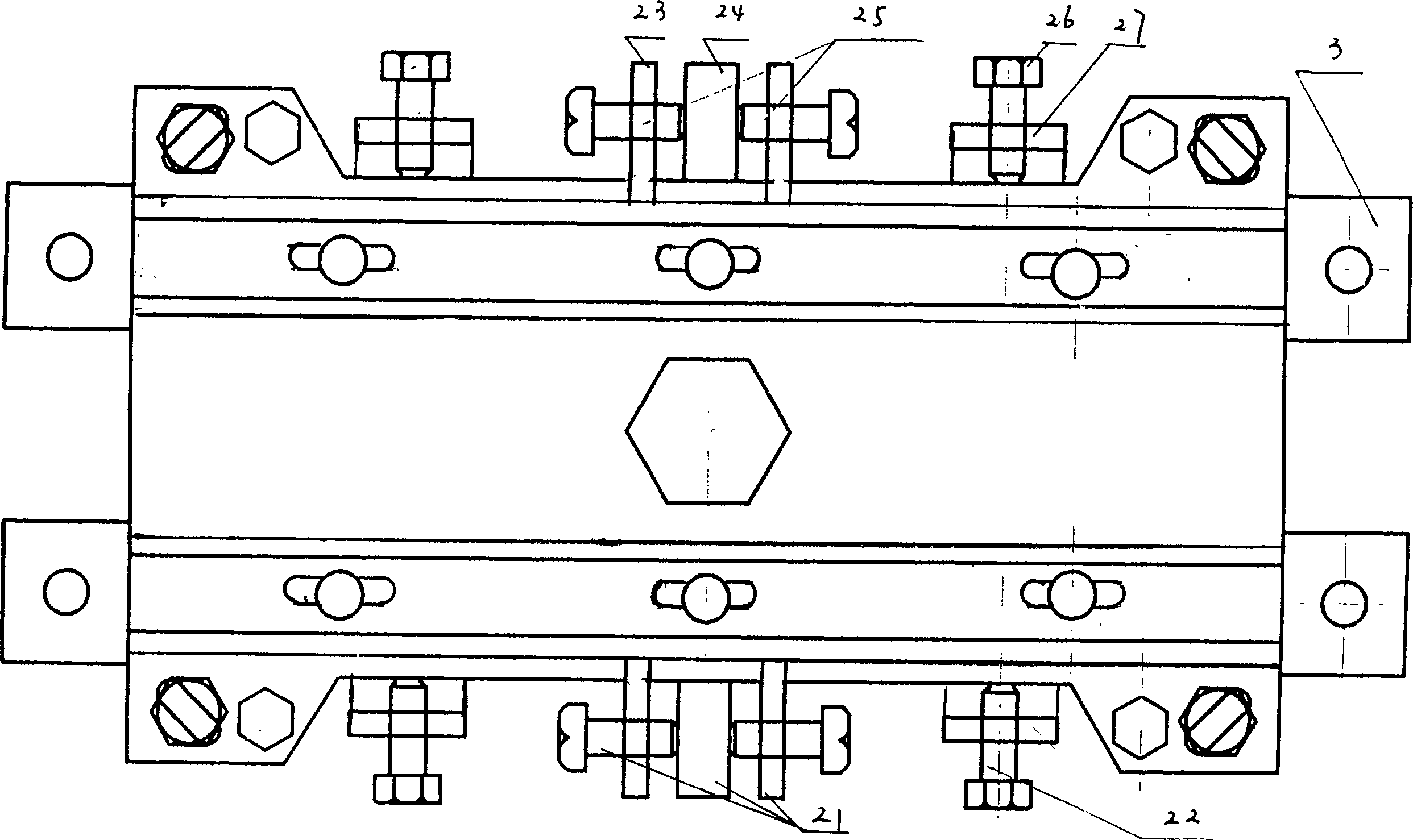

[0015] The lower mold assembly is composed of polytetrafluoroethylene high temperature resistant cloth layer 5 , silicon rubber pad 10 , lower mold 11 , lower connecting plate 12 and lower beam 13 sequentially connected from top to bottom. The two sets of lower beams are installed on the surface of the bag making machine. By adjusting the hand wheel, gear shaft, gear and rack, the whole heat sealing device can be moved forward and backward. The lower mold 11 can be made into a plane or a bag shape as required, and the upper plane must meet the flatness requirements. The upper mold assembly consists of polytetrafluoroethylene high temperature resistant clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com