Bearing device for driving wheel

A technology for driving wheels and bearing devices, applied in rolling contact bearings, bearings in rotating motion, bearings, etc., can solve problems such as failure to reach service life, and achieve the effect of satisfying service life, low cost, and inhibiting wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

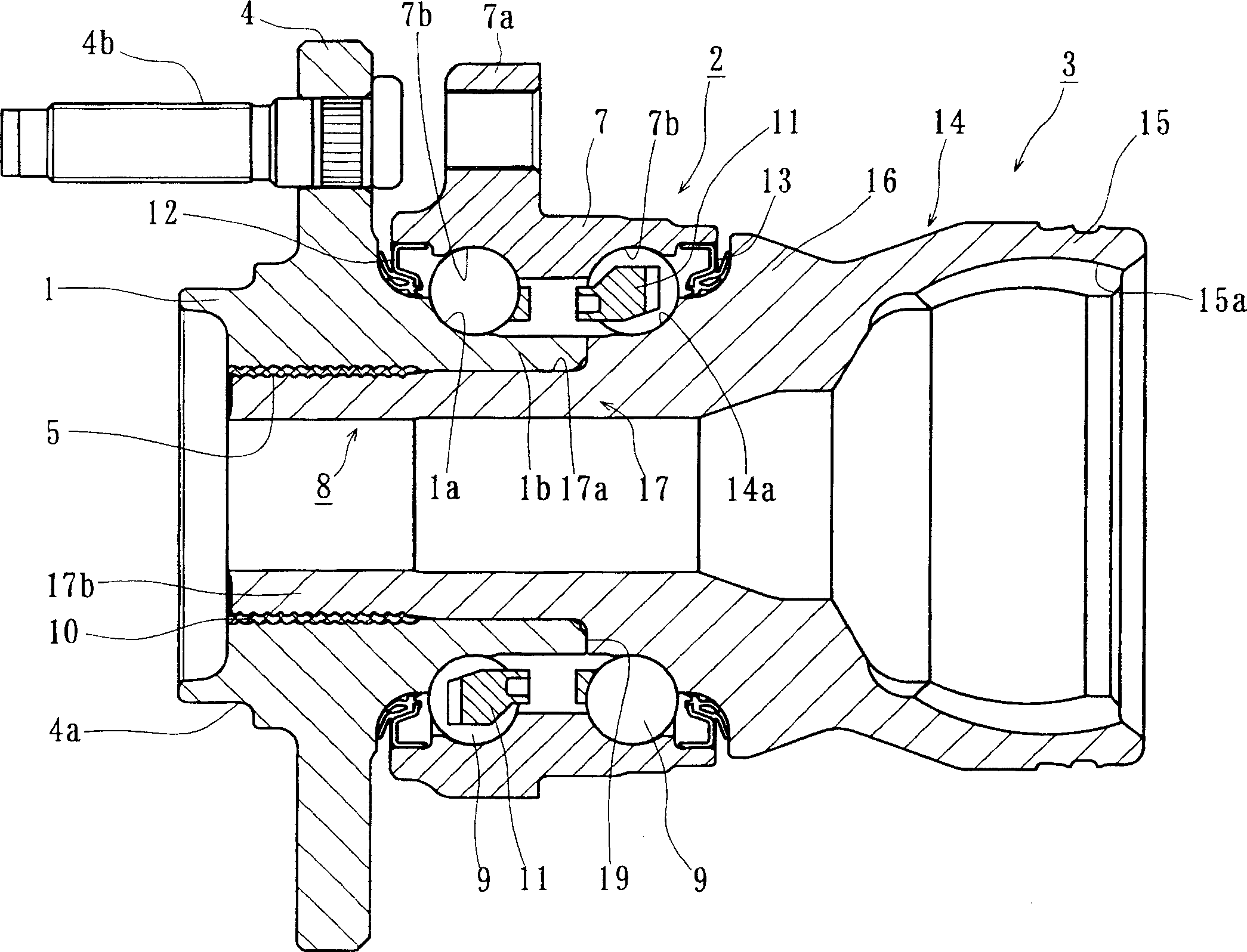

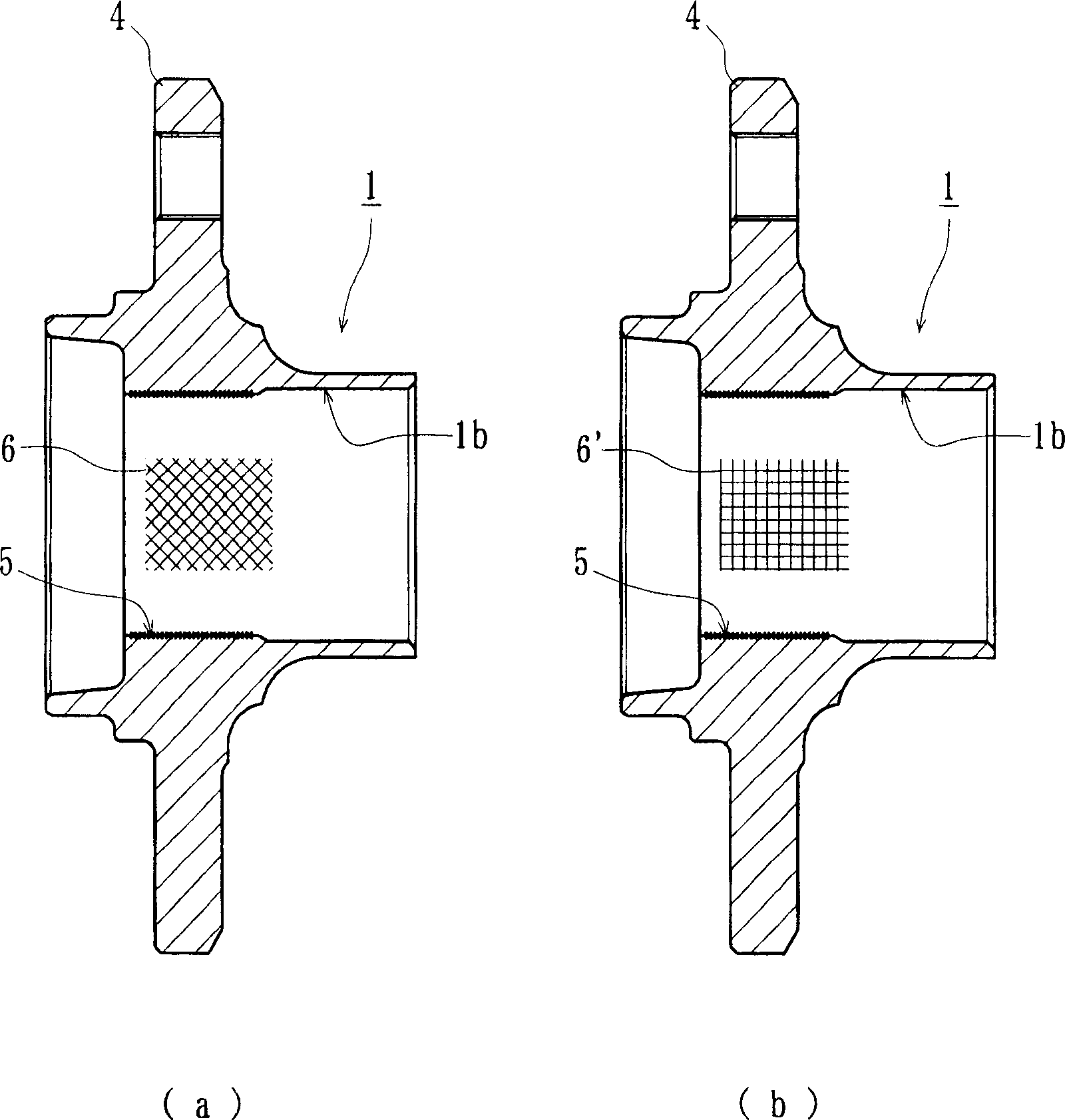

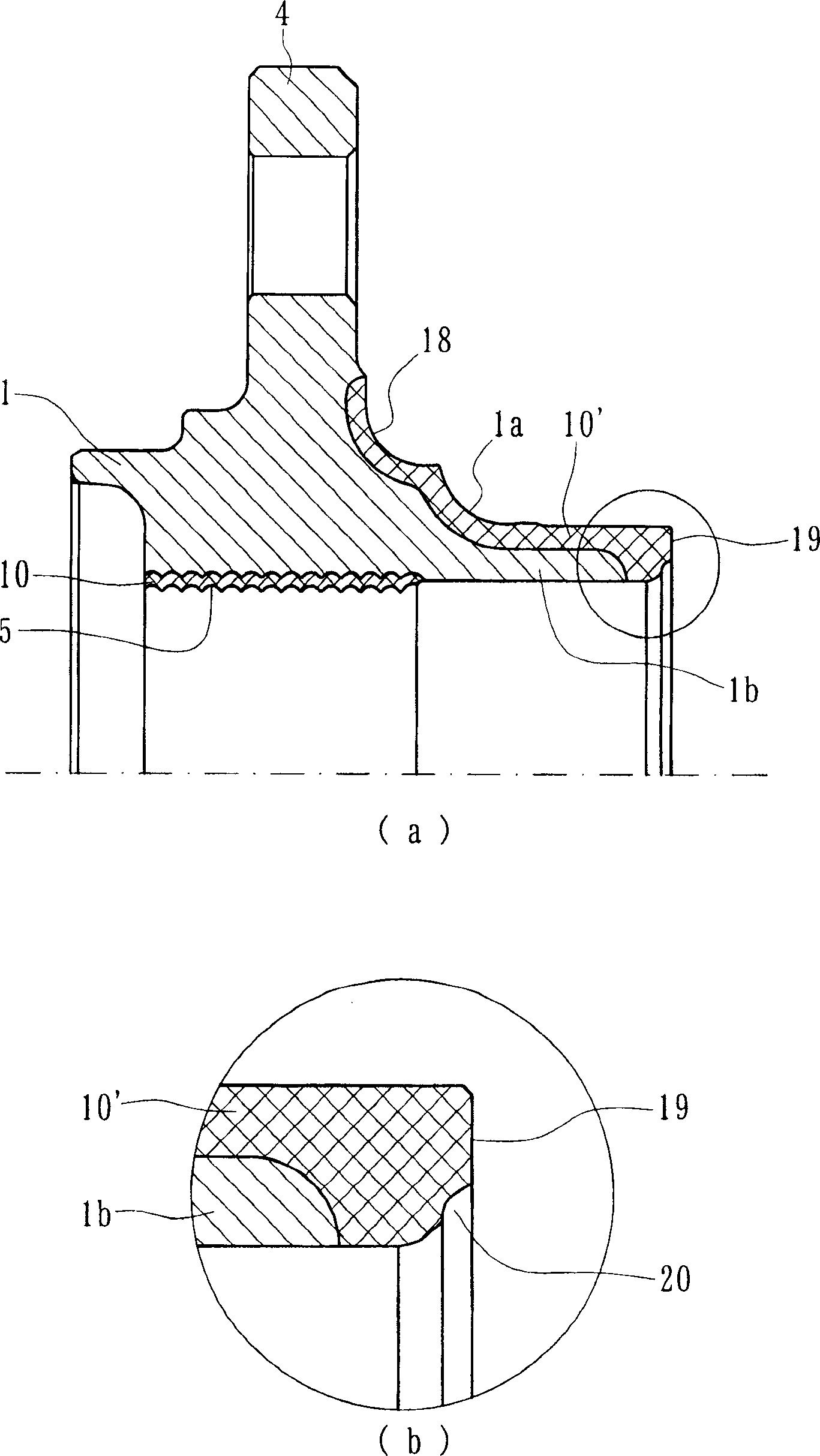

[0057] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional view showing the first embodiment of the bearing device for driving wheels of the present invention.

[0058] Such a bearing device for a drive wheel is composed of a wheel hub 1 , a plurality of rows of rolling bearings 2 , and a universal constant velocity joint 3 . In addition, in the following description, in the state assembled to the vehicle, the side closer to the outer side of the vehicle is referred to as the outer side (left side in the figure), and the side closer to the center is referred to as the inner side (the left side in the figure). on the right side of the ).

[0059] The wheel hub 1 integrally has a wheel mounting flange 4 for mounting a wheel (not shown) on the end of the outer side, and it is useful to erect the wheel mounting flange 4 at equally divided positions in the circumferential direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com