Rubber composition and shockproof rubber and shockproof fittings

A rubber composition, rubber technology, applied in the fields of rubber composition, anti-vibration rubber and anti-vibration accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

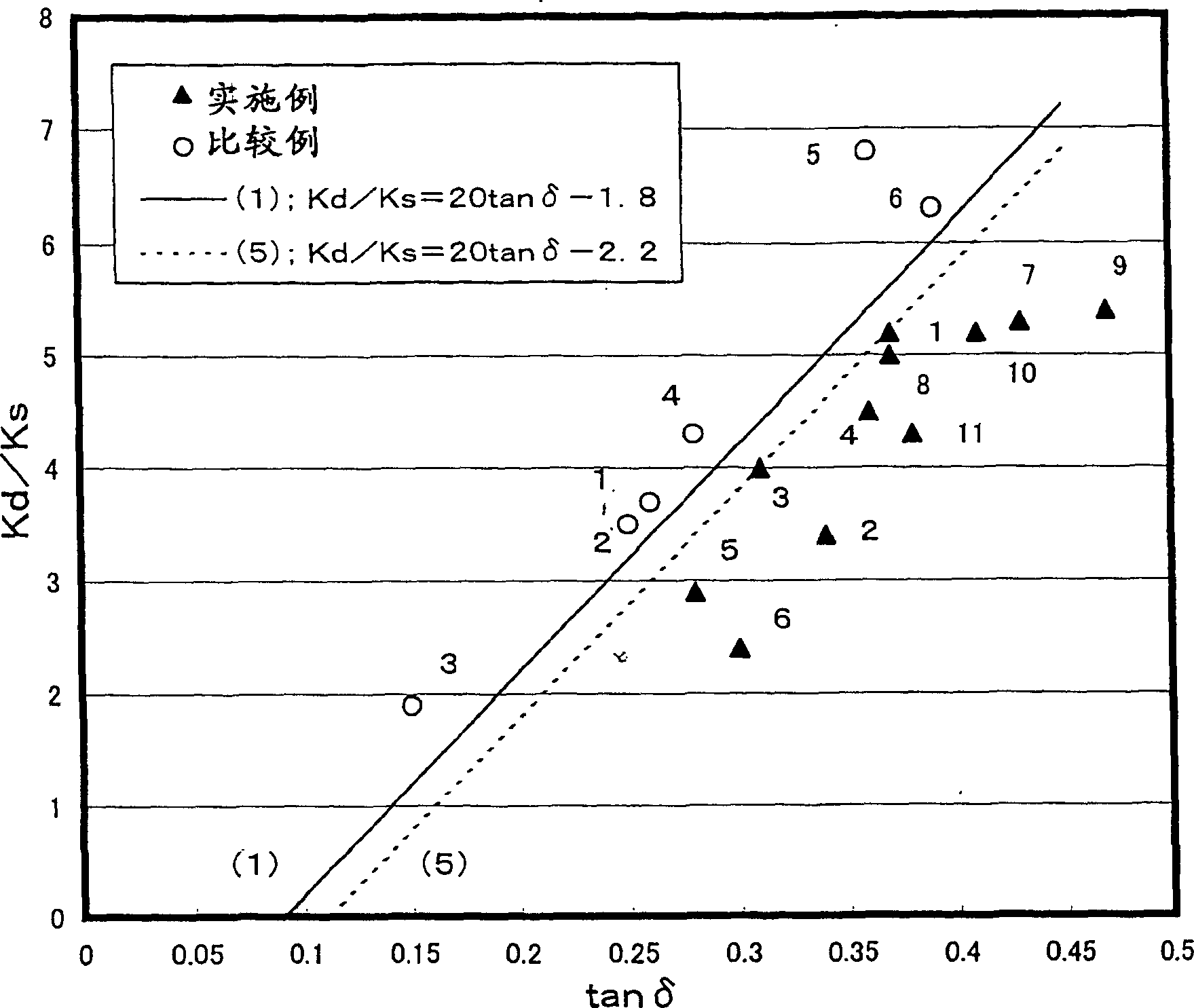

Embodiment 1~11 and comparative example 1~6

[0117] (1) Preparation of rubber composition and manufacture of anti-vibration rubber

[0118] In order to prepare the rubber composition, the styrene-butadiene copolymer rubber (A) and the diene rubber (B) shown in Table 1 were used. Among the components (B) in Table 1, styrene-butadiene copolymer rubber is used other than natural rubber. SL574 is a tin-modified styrene-butadiene copolymer rubber manufactured by JSR Corp. In addition, #1502 is a styrene-butadiene copolymer rubber manufactured by JSR Corp.

[0119] mw

(×10 4 )

Tg(°C)

vinyl content

(%)

Conjugated styrene

ene content

(mol%)

Hydrogenation rate

(%)

ingredient (A)

A-1

1

-5

56

56

0

A-2

5

-16

54

48

85

A-3

10

-40

60

22

0

A-4

0.12

-14

25

...

Embodiment 1

[0134] Example 1: 24 (-40, -16), Example 2: 24 (-40, -16), Example 3: 48 (-53, -5), Example 4: 46 (-51, -5 ), Example 5: 58 (-63, -5), Example 6: 58 (-63, -5), Example 7: 17 (-33, -16), Example 8: 26 (-40, -14), Example 9: 13 (-27, -14), Example 10: 11 (-27, -16), Comparative Example 1: 23 (-63, -40), Comparative Example 5: 4 (- 18, -14).

[0135] Example

1

2

3

4

5

6

ingredient (A)

A-1

20

25

20

20

A-2

25

25

A-3

A-4

A-5

ingredient (B)

SBR-1

55

55

SL574

50

55

SBR-2

50

50

#1502

20

20

30

20

30

30

SBR-3

SBR-4

SBR-5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com