Spouted bed low-temp. pyrolysis method of waste rubber and its equipment

A low-temperature pyrolysis and spouted bed technology, applied in the field of waste treatment, can solve the problems of large construction investment and unsuitability for small and medium-sized enterprises, and achieve the effects of saving energy costs, reducing sulfide content, and improving heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

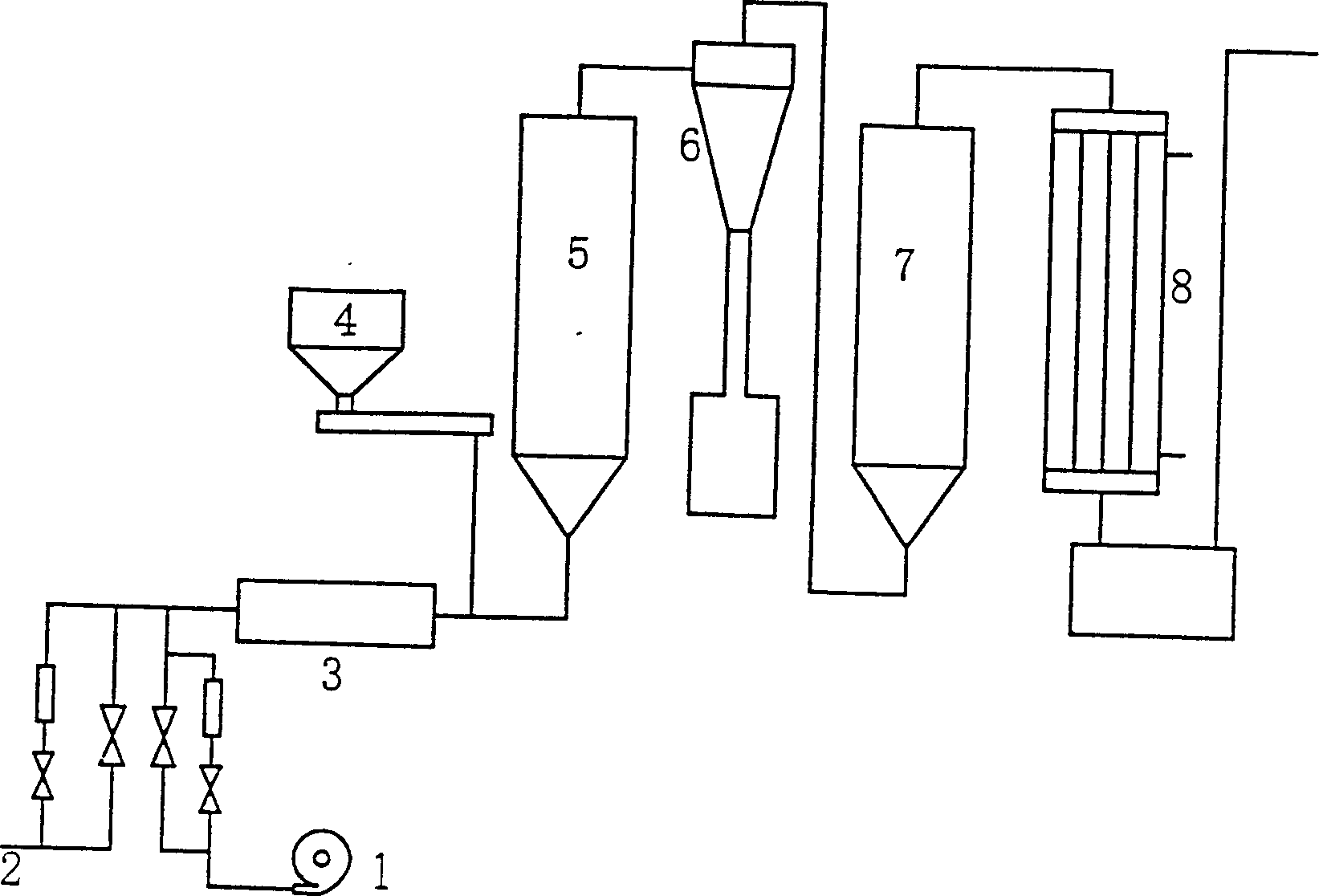

[0021] Such as figure 1 As shown, waste rubber is added into the spouted bed reactor 5 by feeder 4 . The combustible gas 2 and the air are respectively driven by the fan 1 and enter the burner 3 in a certain proportion, and the fan 1, the combustible gas 2 and the burner 3 form a high-temperature flue gas generating part. The flue gas produced by combustion has a certain pressure and velocity, so as to ensure that the rubber particles can be spouted after the flue gas enters the spouted bed reactor 5 .

[0022] Such as figure 2 , 3 As shown, in the embodiment 1 and 2 using the traditional spouted bed or the guide tube spouted bed as the reactor, the rubber particles in the central part of the spouted bed reactor (i.e. the spouting zone) are sprayed upwards at a high speed in dilute phase form during operation. , in the other part of the spouted bed (that is, the annular area) the rubber particles move downward at a low speed in a dense phase.

[0023] Such as Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com