Electronic board of jacquard weave

An electronic jacquard and cardboard technology, applied in cardboard, cardboard punching devices, textiles, etc., can solve the problems of small and medium-sized manufacturers' inability to purchase, low production efficiency, and high labor intensity, and achieve shortened power-on time and service life Long, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

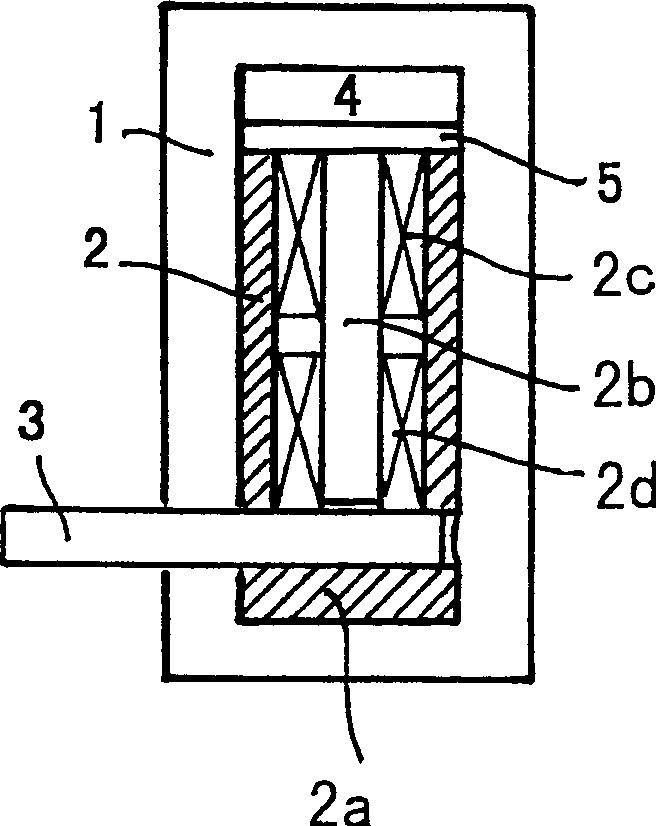

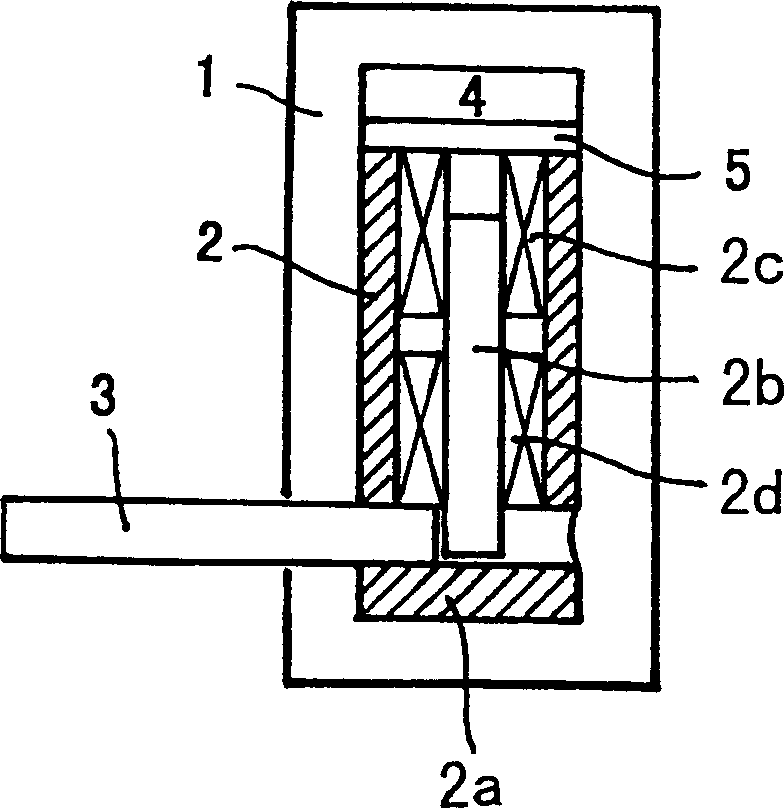

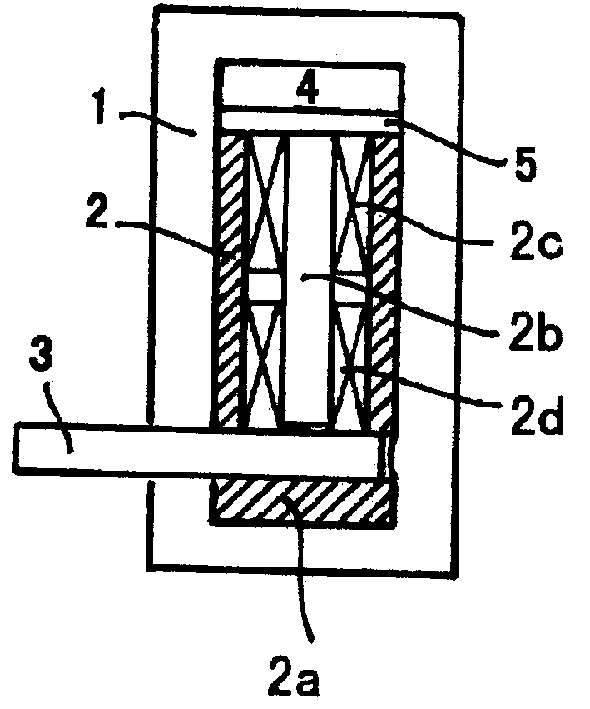

[0009] An electronic jacquard plate for a trademark jacquard loom, with a total of 400 needles, divided into 8 rows, each with 50 needles, the electromagnet base 2a has a length, width and height of 350×400×180mm, and the chassis 1 is made of the original The transmission mechanism drives left and right reciprocating motion, the reciprocating motion speed is 100 times per minute, its displacement is 20mm, the diameter of the electromagnet moving iron core 2b is 3mm, the number of turns of the working coil 2c is 3000 turns, and the number of turns of the reset coil 2d is 3000 turns , the average energizing current of the coils 2c and 2d is 16mA. When the reset coil 2d is energized, the moving iron core 2b moves down, and all the horizontal needles are reset; the working coil 2c is energized, and the corresponding moving iron core 2b moves up at the same time, and is attracted by the permanent magnet 4, and the horizontal needles follow the chassis 1 to the left Moving, the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com