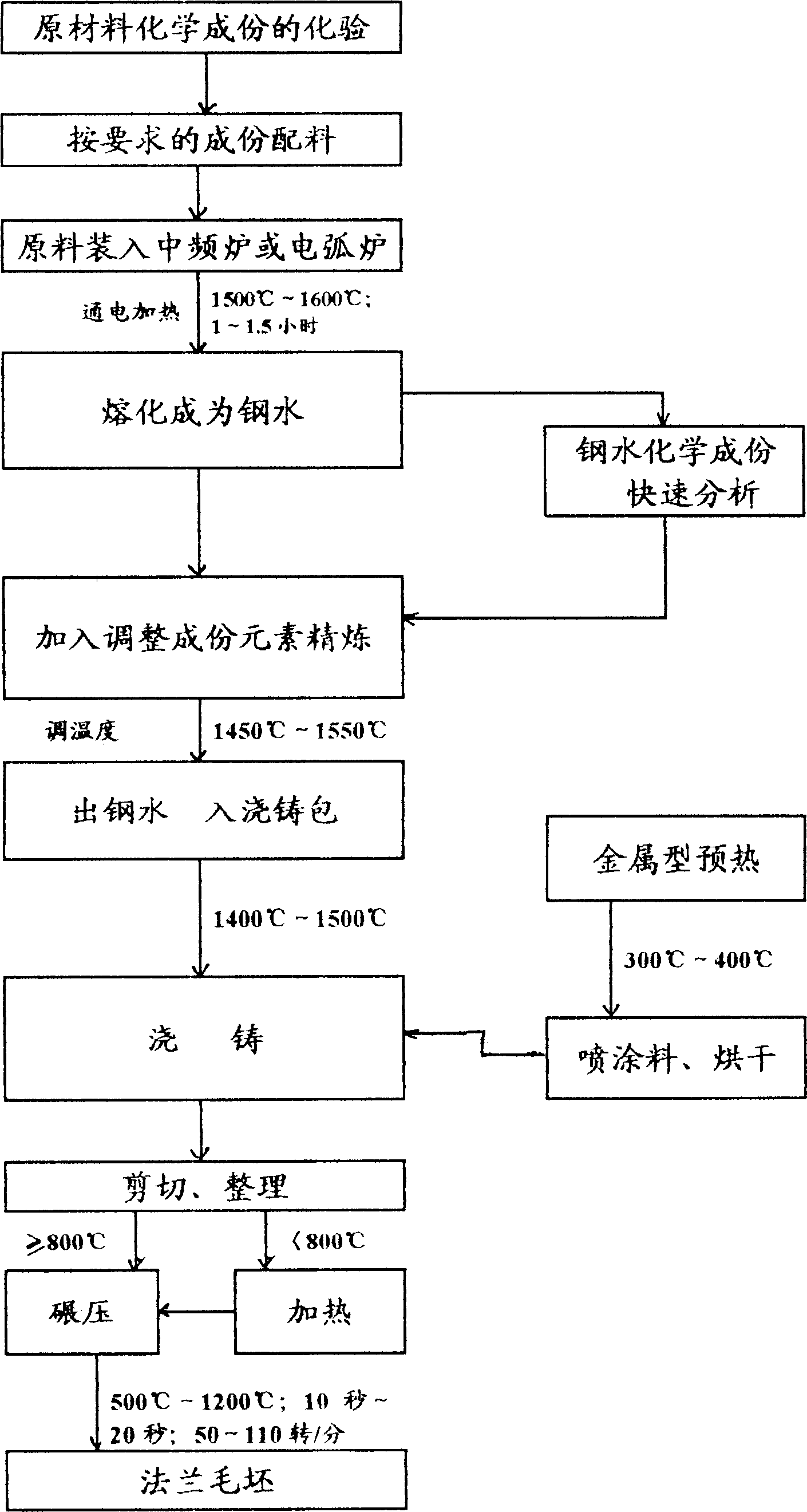

Production process of steel flange blank

A manufacturing process and flange technology, which is applied in the field of steel flange blank manufacturing process, can solve the problems of low manufacturing efficiency, huge investment, and high noise in the workplace environment, and achieve good organizational structure and low equipment requirements. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

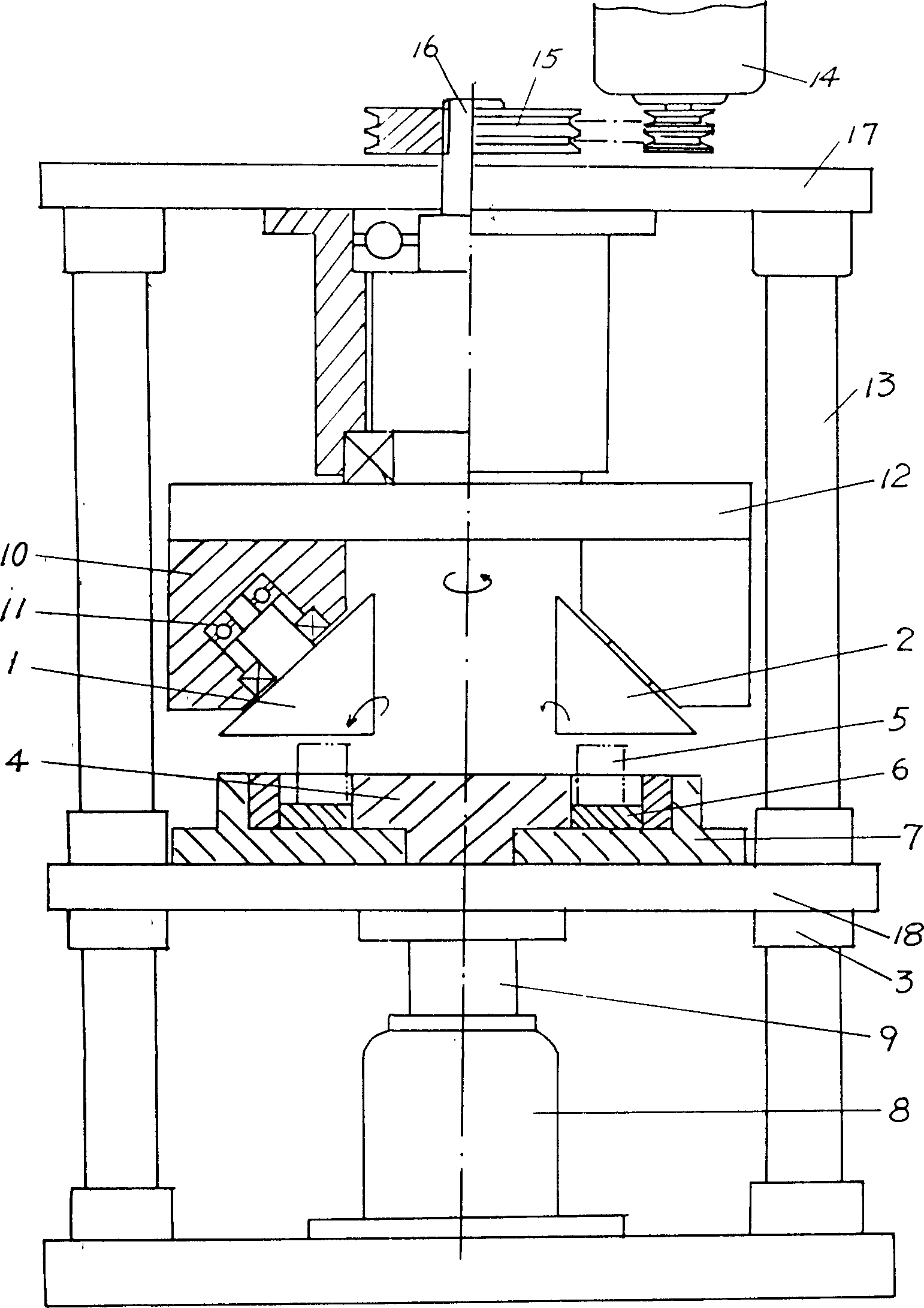

Method used

Image

Examples

Embodiment 2

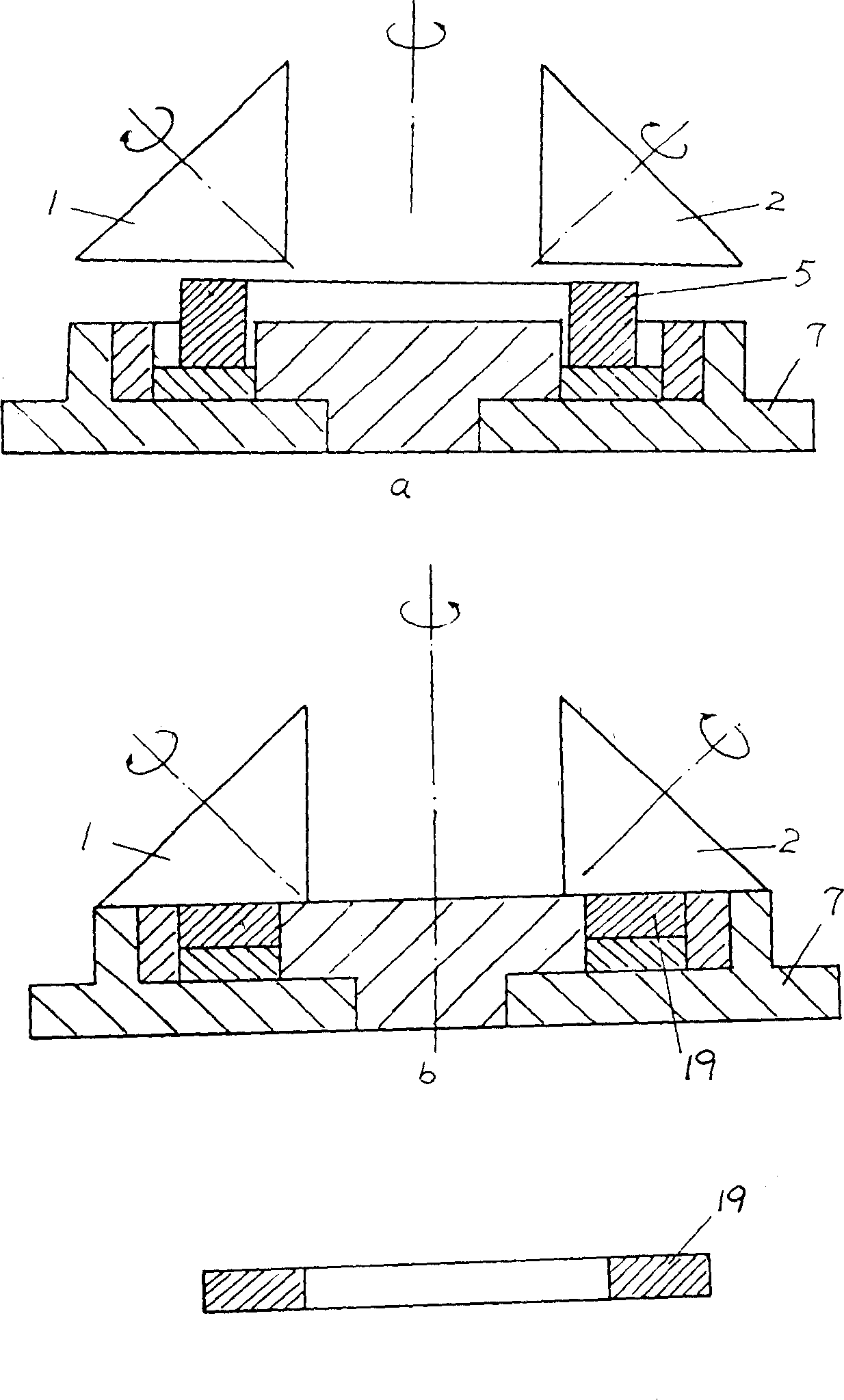

[0017] Take the manufacture of PC500 prestressed pipe pile end plate flange blank as an example, the material is ZG200-400, the thickness obtained through (1) to (5) steps is 40mm, the outer diameter is 345mm, the inner diameter is 200mm, and the temperature is 550°C The casting slab 5 is sent to the conical roller rolling machine of 500 tons of pressure through the raceway, the rolling method and principle are the same as embodiment 1, only a pair of rolling machines 1 and 2 have a rotating speed of 55 rpm, and the rolling time is In 15 seconds, a prestressed pipe pile end plate flange blank 19 with a thickness, outer diameter, and inner diameter of 20mm, 500mm, and 300mm respectively is obtained. Example 3:

Embodiment 3

[0018] Take the manufacture of PC600 prestressed pipe pile end plate flange blank as an example, the material is ZG200-400, the thickness obtained through (1) to (5) steps is 40mm, the outer diameter is 408mm, the inner diameter is 240mm, and the temperature is 700°C The casting slab 5 is sent to the conical roller rolling machine of 350 tons of pressure through the raceway, the rolling method and principle are the same as embodiment 1, only a pair of rolling machines 1 and 2 have a rotating speed of 70 rpm, and the rolling time is In 18 seconds, a prestressed pipe pile end plate flange blank 19 with a thickness, outer diameter, and inner diameter of 20mm, 600mm, and 380mm respectively was obtained. Example 4:

Embodiment 4

[0019] Taking the flat flange blank used for manufacturing pipes as an example, the material is Q235 steel, and the mold is replaced with the mold for manufacturing flat flange blank. Send the slab 5 obtained through steps (1) to (5) with a thickness of 70mm, an outer diameter of 575mm, an inner diameter of 450mm, and a temperature of 1150°C through the raceway to a 200-ton conical roller compactor for rolling. The method and principle are the same as in Example 1, except that a pair of rolling rollers 1 and 2 are 100 rpm, and the rolling time is 20 seconds, thereby obtaining a pipeline with a thickness of 36mm, an external diameter of 860mm, and an internal diameter of 700mm Use flat flange blanks. Example 5:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com