Production method of off-axis paraboloid mirror

An off-axis parabolic mirror and manufacturing method technology, applied in manufacturing tools, glass manufacturing equipment, lenses and other directions, can solve the problems of large diameter of parent parabolic mirror, rising processing cost, inability to process, etc., to achieve convenient measurement, reduce processing cost, Instrument Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

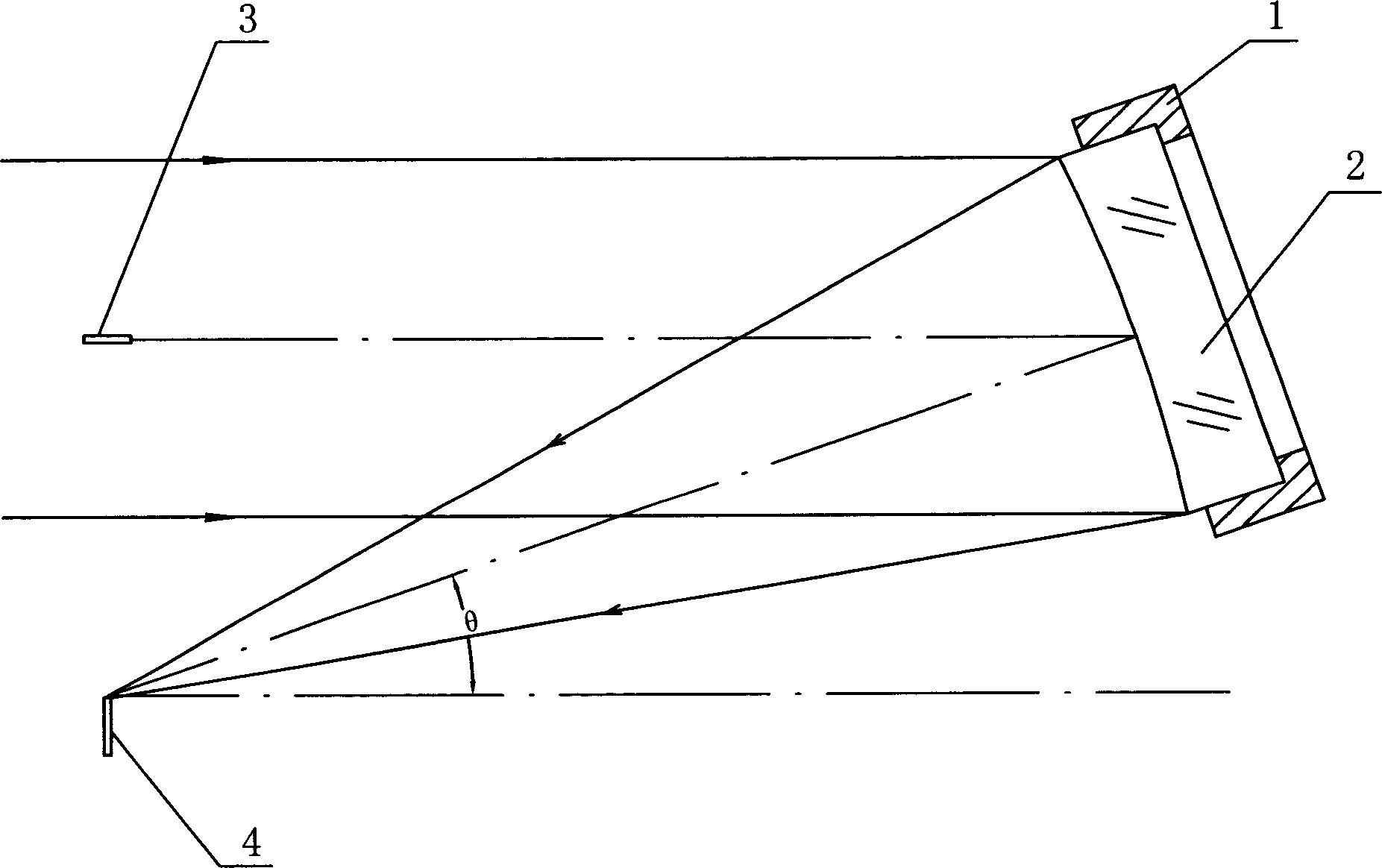

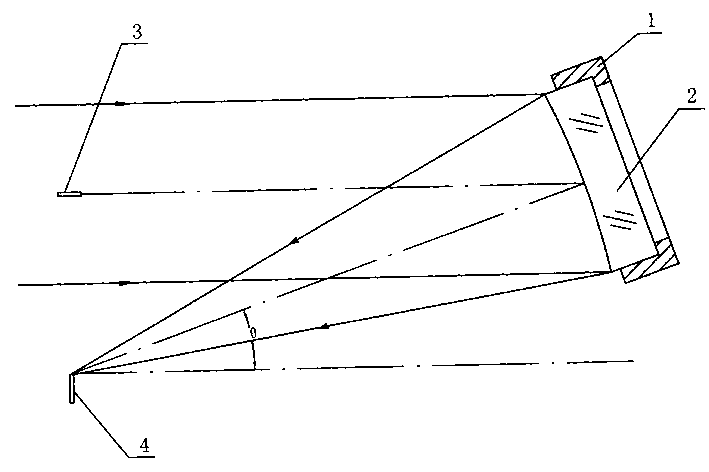

[0030] Example one: see attached figure 1 As shown, the manufacturing method of the present invention is used to make an off-axis parabolic mirror with a diameter of Ф=420 mm and the focal length of the parent parabola f 0 = 5000 mm, off-axis amount H = 700 mm, including the following steps:

[0031] (1) Making mirror blanks;

[0032] (2) Design and process a metal square mirror frame 1, put the mirror blank 2 into the mirror frame 1, with the mirror surface facing up, 2 mm to 3 mm above the surface of the mirror frame 1, and the gap between the mirror blank 2 and the mirror frame 1 is 0.3 mm to 0.4 Millimeters, insert 4 plastic sheets with a thickness of 0.10 to 0.15 mm at equal distances along the periphery of the lens blank, and seal the gap around the gap with medical white tape to prevent the polishing liquid from flowing in; engrave a line in the center of one side of the lens frame and follow this one Line, also engrave a mark on the place where the lens blank 2 is higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com