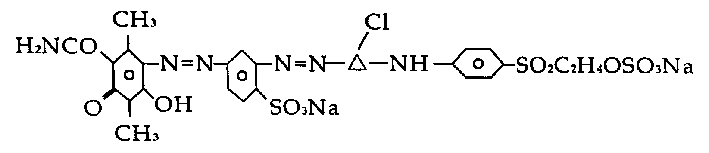

Complex reactive bright yellow dyeÔàí"

A reactive bright yellow and dye technology, applied in the direction of organic dyes, can solve the problems of poor color brightness, low color fastness, and difficult washing, and achieve the effects of reducing impurities, increasing solubility, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preparation of a kind of complex active bright yellow dye B-6GLN of the present invention is: dissolving p-(vinylsulfone-based sulfate) aniline, carrying out diazotization after filtration, then condensation, coupling, salting out, filtration and drying to obtain Monomer B-6GLN reactive bright yellow dye. Mix the monomer B-6GLN active bright yellow dye, dustproof agent and co-solvent in the following ratio: B-6GLN60-94%, butyl oleate 1-10% and co-solvent 5-30%, and grind to the required particle size .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com