Online portable multi-functional intellgence fluid density meters

A liquid density and portable technology, which is applied to determine the specific gravity and other directions by measuring the pressure difference. It can solve the problems of tank containers that can only be applied on the ground, the requirements of the measurement medium are harsh, and the secondary calibration cannot be performed, so as to save money. and installation costs, easy installation, and thin pipe diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

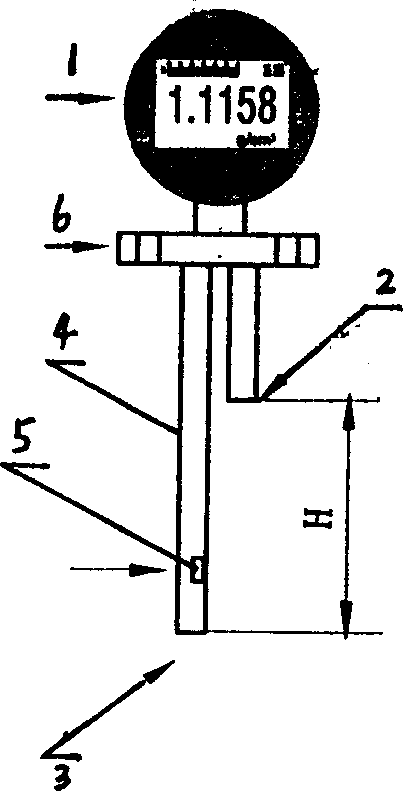

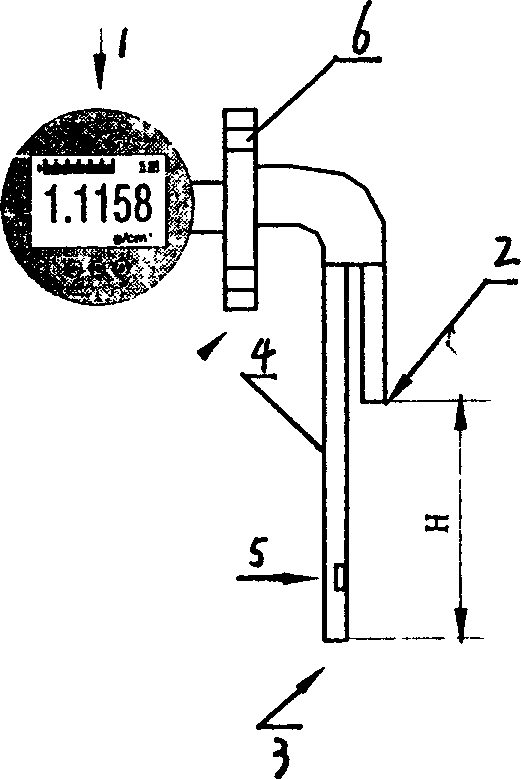

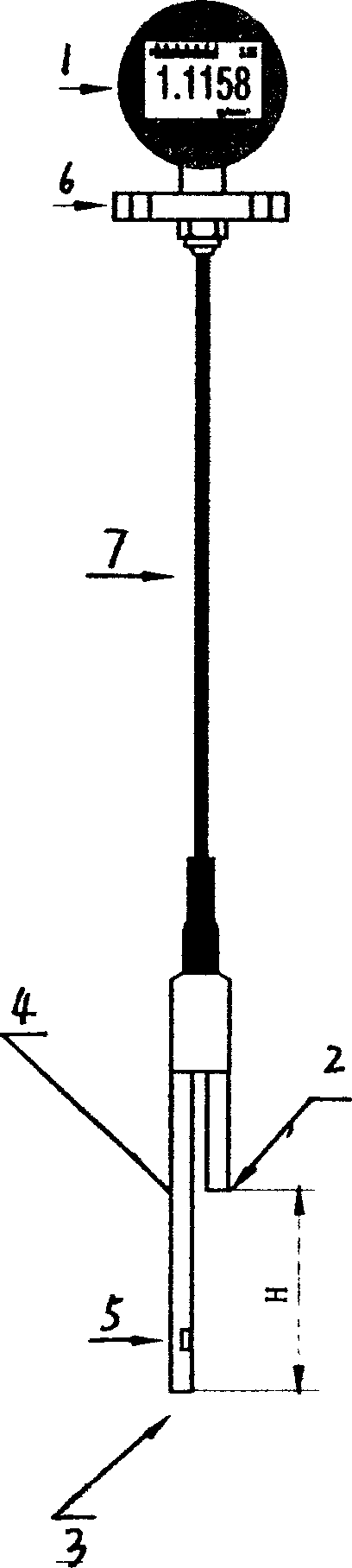

[0029] The present invention includes two parts: a temperature density sensor and an intelligent display record controller. The principle of the density probe is: the top sensor and the bottom sensor form a differential pressure sensor, and the top sensor and the bottom sensor respectively detect the pressure of the upper and lower points through the isolation diaphragm. The vertical height between them is H. By precisely calibrating the pressure difference between the top sensor and the bottom sensor and measuring the H value, the static pressure principle of liquid substances is used: density = pressure / height, and then the linearity is adjusted by the software programmed into the microcontroller. Errors, temperature errors and other non-correlation errors are precisely corrected to achieve accurate measurement of density parameters. Referring to Fig. 1, the intelligent display recording controller 1 is connected to the density sensor through a mounting flange 6, the density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com