Hypereutectoid alpax with eutectic structure and technological method thereof

A technology of eutectic structure and aluminum-silicon alloy, which is applied in the field of hypereutectic aluminum-silicon alloy to achieve the effect of avoiding shrinkage porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

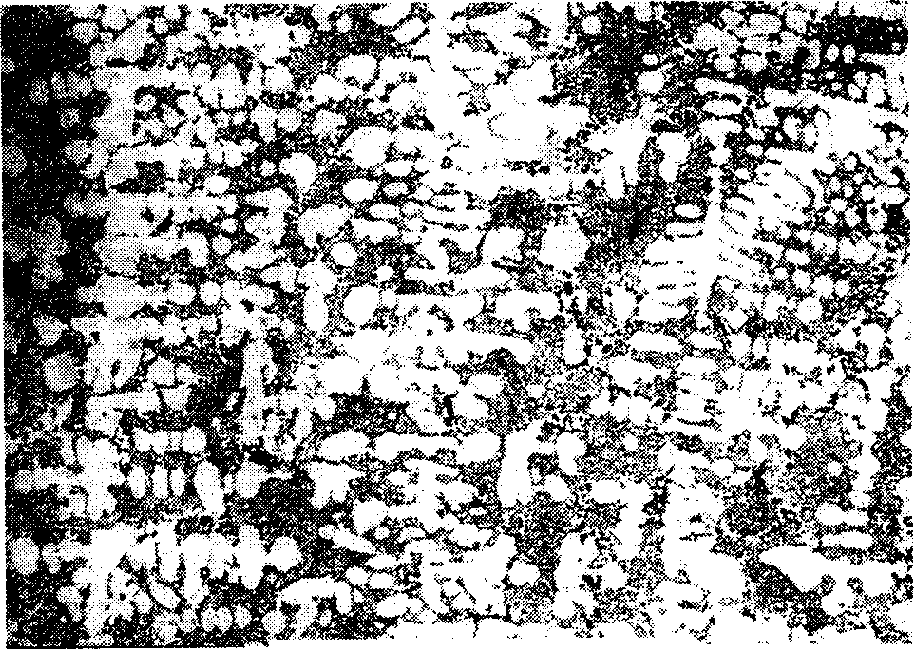

[0024] Hypereutectic aluminum-silicon alloy chemical composition Si13.7%, Cu0.98%, Mg0.55%, Mn0.49%, Ni0.30%, Zn0.010%, Fe0.26%, Ti0.08%, Srfigure 1 Description), Al-25% Si master alloy. Melt in a resistance furnace. Raise the temperature to 720°C and degas with nitrogen. After 15 minutes of heat preservation, pour into the metal mold preheated to 300°C. The sample size is 45×50×120mm. In the as-cast metallographic structure of the alloy (see figure 2 ) does not appear primary silicon phase, aluminum silicon eutectic and a large number of dendritic primary aluminum phase as the main composition. The silicon phase in the center of the eutectic is metamorphic, extremely fine and distorted, while the eutectic silicon on the grain boundaries is somewhat coarsened. It shows that the hypereutectic aluminum-silicon alloy with electrolytic aluminum-silicon alloy as the main body can still maintain the original self-modifying property after adding a small amount of silicon.

Embodiment 2

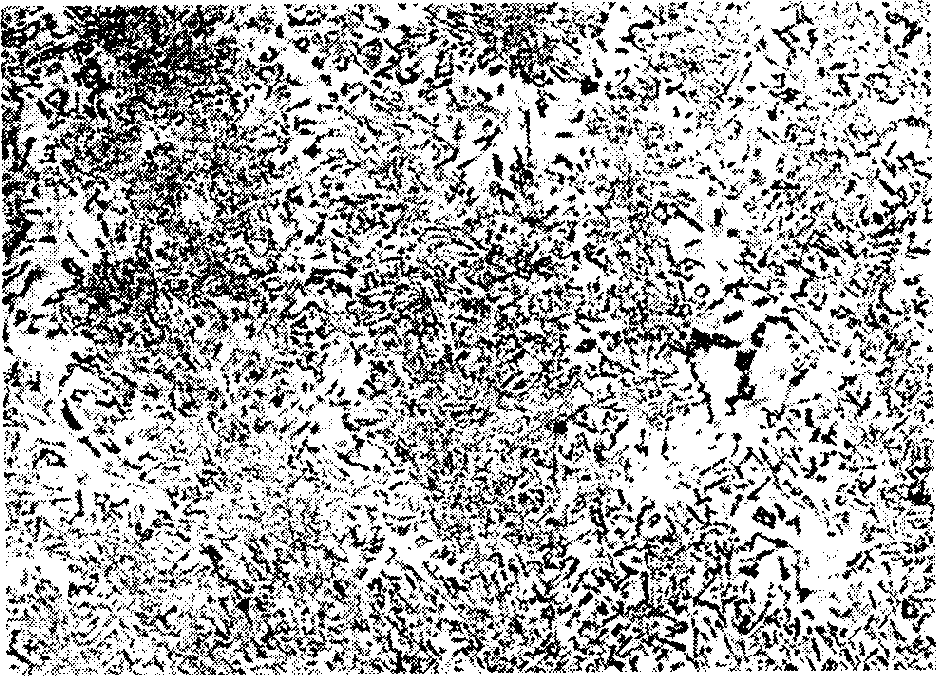

[0026] The chemical composition of the hypereutectic aluminum-silicon alloy is Si15.4%, Cu1.05%, Mg0.52%, Mn0.50%, Ni0.28%, Zn0.010%, Fe0.32%, Ti0.08%, Sr0 .001%. The charge composition and melting process are as in Example 1. The as-cast structure of the alloy is basically composed of Al-Si eutectic, and a small amount of primary Al phase is distributed on the Al-Si eutectic grain boundary. Eutectic silicon is under-modified, and a considerable part is in the form of short rods ( image 3 ) and appear angular primary silicon phases with a size of about 10 μm ( Figure 4 ). It shows that when more Al-25% Si master alloy is added, the inherent self-modification performance of the electrolytic aluminum-silicon alloy is greatly reduced due to too many undissolved silicon crystals. At this time, there is also a slight silicon phase floating

Embodiment 3

[0028] The chemical composition of the hypereutectic aluminum-silicon alloy is Si15, 7%, Cu1.00%, Mg0.55%, Mn0.50%, Ni0.28%, Zn0.010%, Fe0.33%, Ti0.09%, Sr0 .0051%. Charge composition and melting process are the same as Example 1. After degassing, Al-10% Sr master alloy is added for modification treatment. Stir well and let sit for another 15 minutes before pouring. The sample is the same as Example 2. The as-cast metallographic structure of the alloy is basically composed of Al-Si eutectics, and each eutectic is surrounded by the Al phase ( Figure 5 ). The silicon phase in the center of the eutectic has been fully modified and is very fine, but the silicon phase on the grain boundary is distributed in the form of short rods on the aluminum matrix in a radial manner. The amount of aluminum phase is greatly increased than that of the alloy without strontium modification (Example 2). It shows that when the silicon content of the alloy is close to 16% of the non-equilibriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com