Terminal box apparatus for solar energy battery module

A technology of solar cells and terminal boxes, applied in photovoltaic modules, roofs using tiles/slate tiles, roofs using flat/curved panels, etc., can solve problems such as reducing the service life of peripheral components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

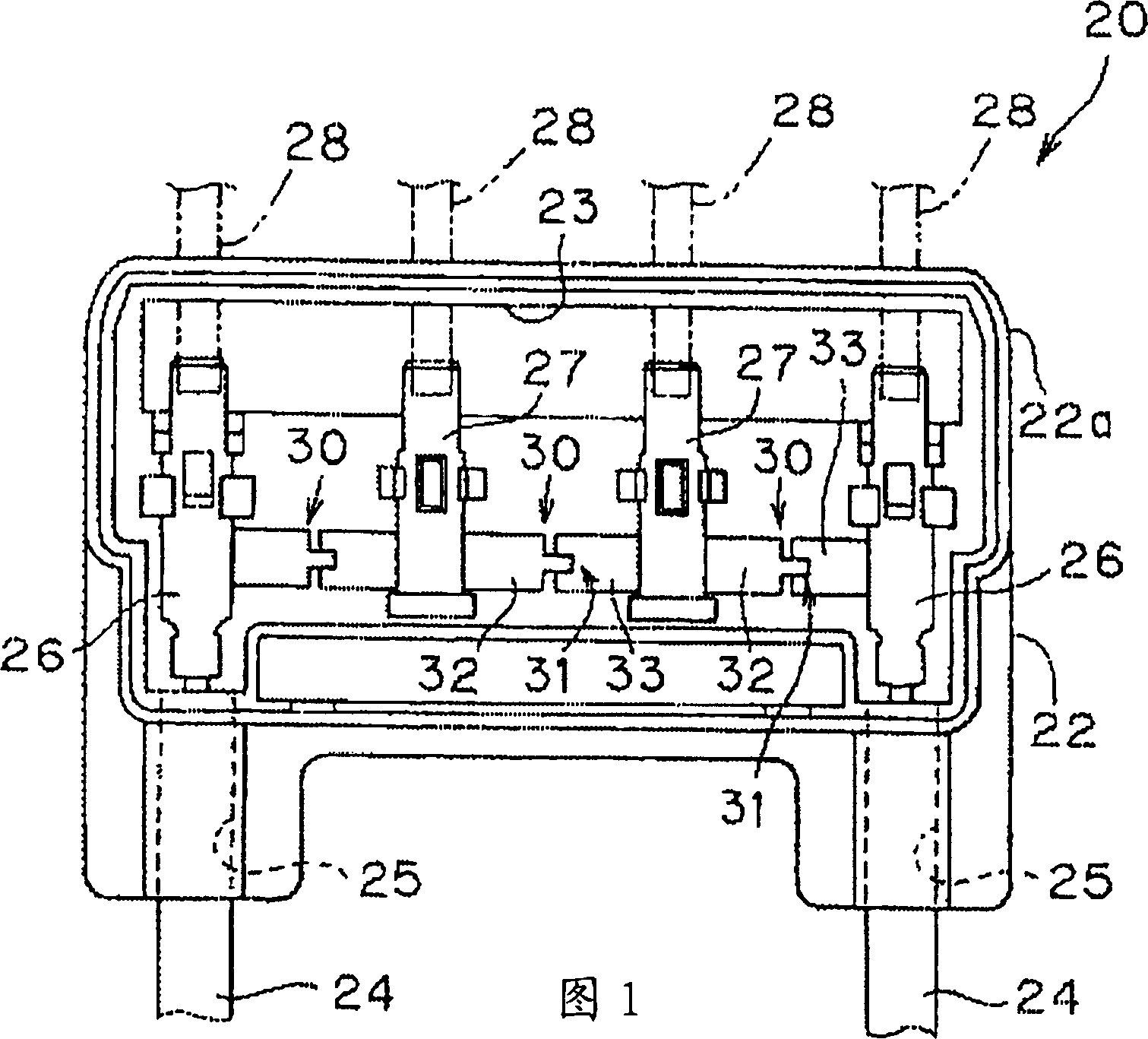

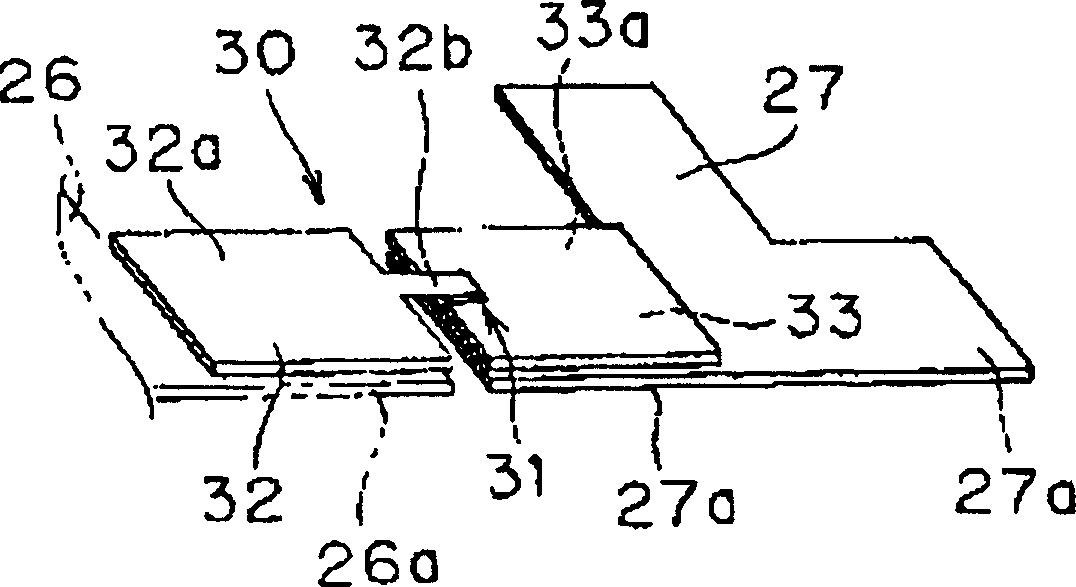

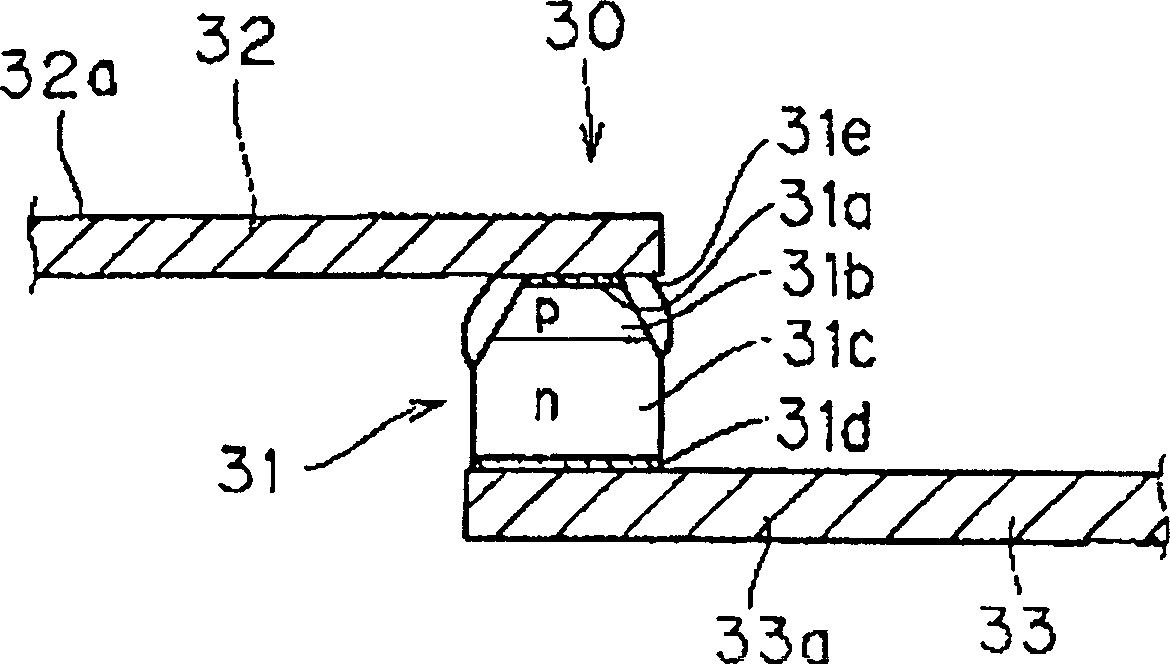

[0047] FIG. 1 shows a terminal box arrangement 20 for a solar cell module. As described above, the terminal box device 20 is located on the back of the solar cell module, and the solar cell (battery pack) is formed on the surface of the module. The solar cells function as photoelectric conversion elements connected in series.

[0048] The terminal box device 20 has a box 22 formed by molding synthetic resin. The box 22 is a roughly rectangular box body 22a, the box body has an accommodating space and an open upper surface. The case 22 also has a plate-shaped cover (not shown) mounted on the upper surface of the case body 22a so as to cover the accommodation space.

[0049] Similar to the conventional structure, the lower surface of the box body 22a of the terminal box device 20 is glued to the back of the solar cell module box body with an adhesive. In order to protect against water, moisture, heat radiation and condensation, the cover is glued to the case body 22a by silic...

no. 2 example

[0061] Figure 4 A bypass diode 30 of a second embodiment is shown. Components in the second embodiment that are the same as those in the first embodiment are denoted by the same symbols as in the first embodiment, and their descriptions are omitted.

[0062] In the second embodiment, in the vicinity of the protruding portion 32b of the guide plate 32 of the bypass diode 30, the guide plate 32 is cut from both sides in the direction of extension (length) of the guide plate so as to be perpendicular to the guide plate. The direction of extension (width) of 32 forms two deep slits 35, thereby forming a Z-shaped portion 32c.

[0063] A rectangular portion without the notch 35 is used as the heat radiation portion 32a. The guide plate 32 is made of metal, and its thickness is less than 0.1mm. Similar to the first embodiment, in bypass diode 30, heat radiation portions 32a and 33a are welded in layers to heat radiation portion accommodating members 26a and 27a protrudingly forme...

no. 3 example

[0067] Figure 5 A third embodiment is shown. Components of the third embodiment that are the same as those of the first embodiment are denoted by the same symbols as those of the first embodiment, and their descriptions are omitted.

[0068] In the third embodiment, the heat radiation portions 32a and 33a of the guide plates 32 and 33 of the bypass diode 30 are respectively welded on the heat radiation portion accommodating elements 26a and 27a of the connection terminals 26 and 27, placed on the heat radiation portions 32a and 27a. A rectangular heat radiating metal plate 37 between 33a has almost the same shape and size as the heat radiating portions 32a and 33a.

[0069] Thus, the third embodiment has similar effects to the first embodiment, and improves the heat radiation effect due to the provision of the heat radiation plate 37 to increase the heat capacity.

[0070] Due to the heat radiation effect exhibited by the heat radiation plate 37, it is possible to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com