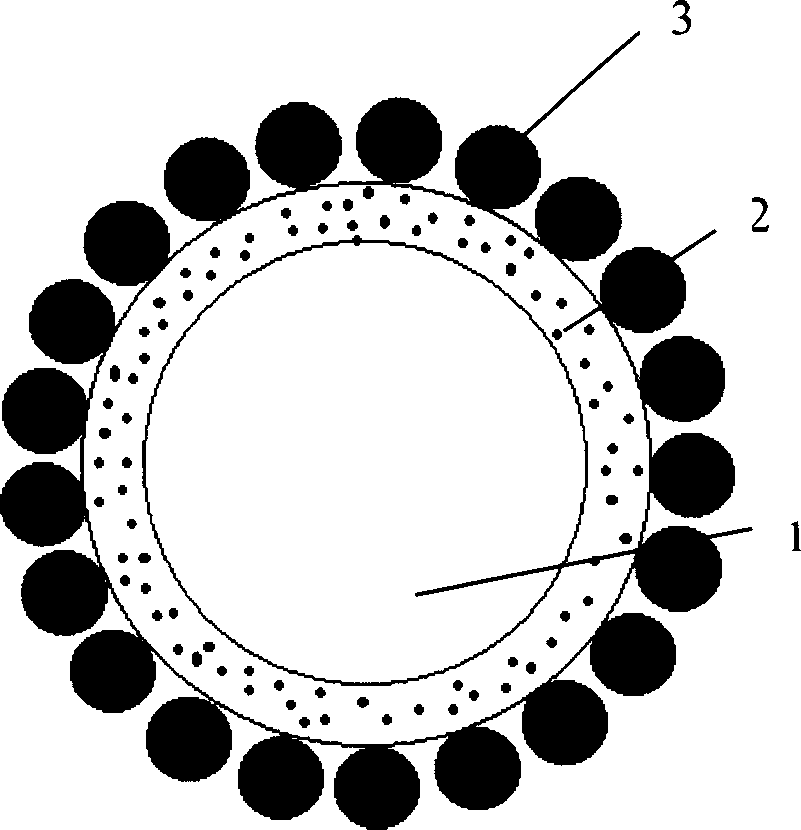

Magnetic superfine solid acid catalyst in double-shell structure and its prepn process

A solid acid catalyst, solid acid technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] FeCl 2 4H 2 O solution (0.1mol / l) and FeCl 3 ·6H 2 Add O solution (0.1mol / l) into a three-necked flask at a ratio of 5:1, place it in a constant temperature water bath at 65°C, add 0.1mol / l NaOH dropwise while stirring, until the pH value of the solution reaches 12, and continue to age with constant temperature stirring 30min. Use a magnetic field to separate the magnetic substrate from the supernatant. Wash with deionized water until the pH value of the solution is close to 7, and the black magnetic core Fe can be obtained. 3 o 4 .

[0022] Take the Fe that is made into 0.0025mol suspension 3 o 4 Add 50ml into a three-necked flask, place it in a constant temperature water bath at 50±1°C and stir, add 1mol / l NaOH dropwise to make the pH of the solution reach 9. 0.025mol ethanol solution of tetraethyl orthosilicate (1.9mol / l) was added dropwise, and 1mol / l NaOH was added dropwise at the same time to keep the pH of the reaction solution at 9 all the time. After ...

Embodiment 2

[0026] According to the method of embodiment 1, with 50ml Fe 3 o 4 (0.0025mol) with 100ml ZrOCl 2 .8H 2 O (0.0125mol) can be used as raw material to prepare ZrO 2 with Fe 3 o 4 ZrO with a molar ratio of 5:1 2 / Fe 3 o 4 Carrier with magnetic, according to 25%wt loading capacity, use Zr(SO 4 ) 2 4H 2 O solution was impregnated at room temperature for 6 h, filtered and dried to obtain Zr(SO 2 ) 2 / ZrO 2 / Fe 3 o 4 catalyst.

[0027] 0.6 g of the above catalyst was weighed and put into the reaction system as in Example 1, and the esterification conversion activity of the catalyst was measured to be 98%.

Embodiment 3

[0029] According to the method of Example 1, finally press 25%wt loading capacity, use SO 4 2- -ZrO 2 impregnated SiO 2 / Fe 3 o 4 , to get SiO 2 with Fe 3 o 4 SO with a molar ratio of 10:1 4 2- -ZrO 2 / SiO 2 / Fe 3 o 4 Magnetic solid acid catalyst.

[0030] 0.6 g of the above catalyst was weighed and put into the reaction system as in Example 1, and the esterification conversion activity of the catalyst was measured to be 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com