Sensitizing method of emulsified explosive and gas flow nozzle used

A technology of airflow nozzles and emulsion explosives, applied in explosives, explosives processing equipment, injection devices, etc., can solve the problems of small output, low efficiency, and rising product costs, and achieve the effects of large output, good storage, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

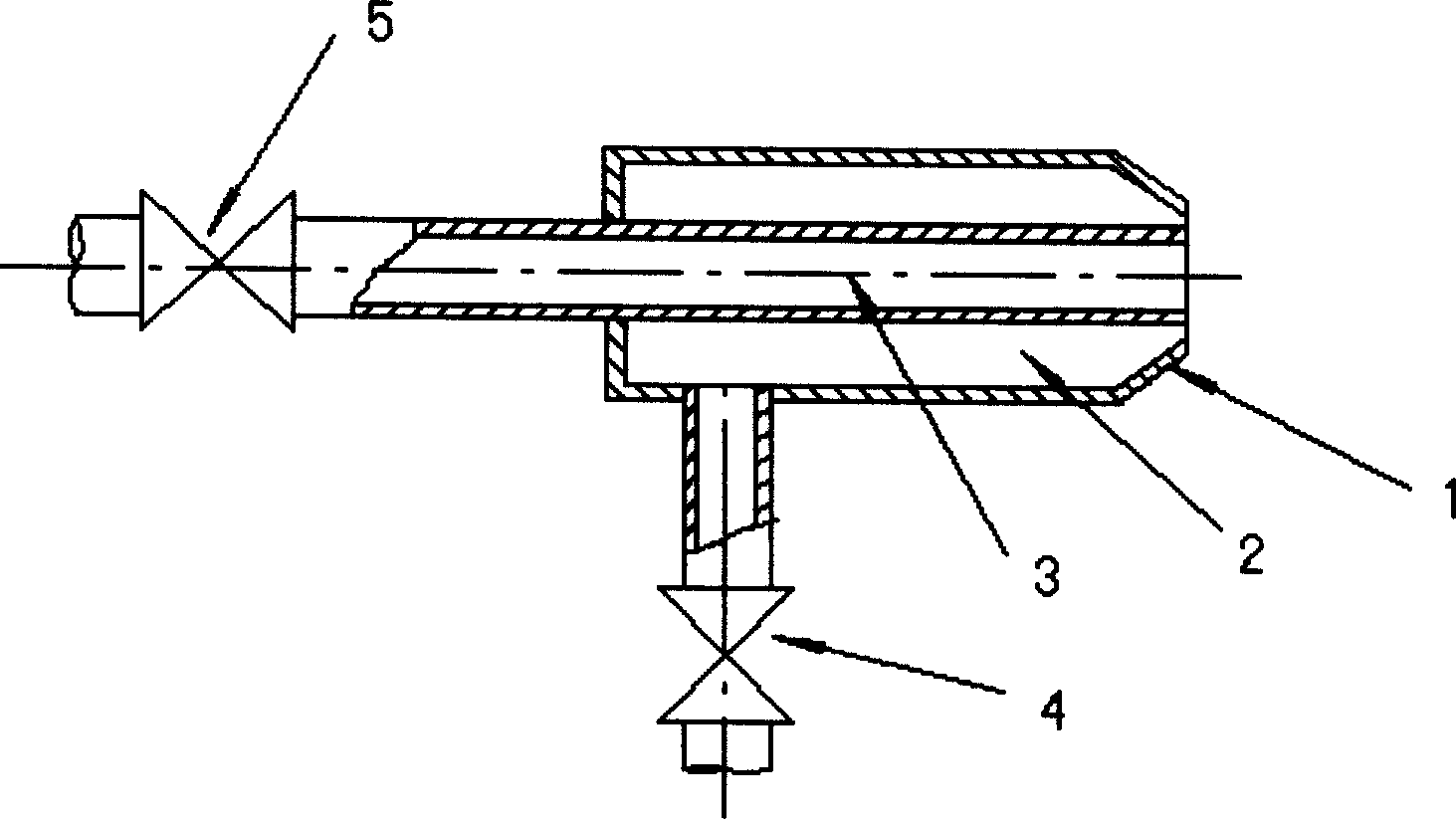

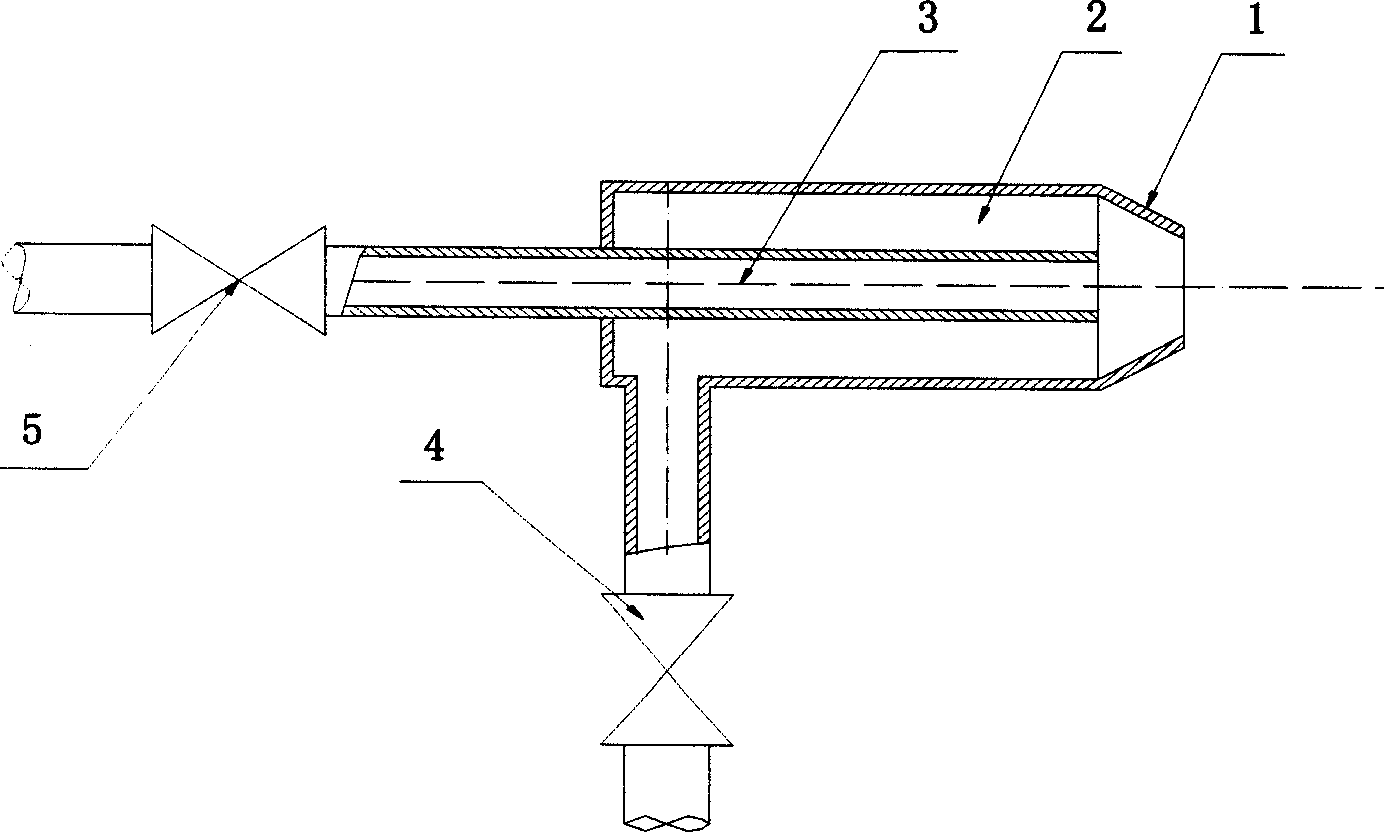

[0016] Example 1: Connect compressed air with a pressure of 5.5kg into the compressed air channel 2, and put the compressed air at a temperature of 110°C and a density of 1.41g / cm 3 1. The emulsified matrix with a flow rate of 3t / h is connected to the emulsified matrix channel 3 and atomized through the second-flow nozzle. During the atomization process, the emulsified matrix is filled with gas while cooling to achieve the effect of sensitization. The resulting explosive density is 1.20g / cm 3 , the temperature is 38°C, and the detonation velocity of the explosive is 4600m / s.

Embodiment 2

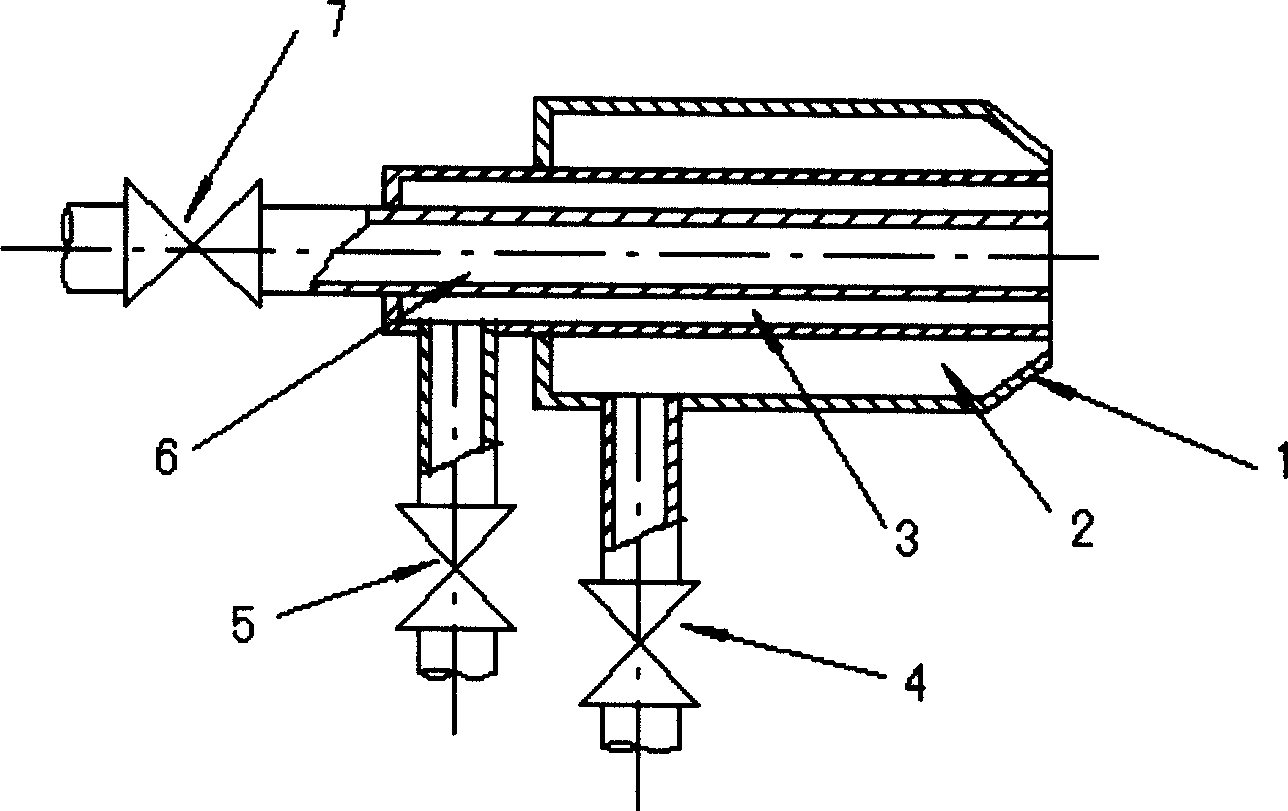

[0017] Example 2: Connect compressed air with a pressure of 4.5kg into the compressed air channels 2 and 6, set the temperature to 110°C and the density to 1.41g / cm 3 1. The emulsification matrix with a flow rate of 3t / h is connected to the emulsification matrix channel 3 and atomized through the three-flow nozzle. During the atomization process, the emulsified matrix is filled with gas while cooling to achieve the effect of sensitization. The resulting explosive density is 1.10g / cm 3 , the temperature is 40°C, and the detonation velocity of the explosive is 5100m / s.

Embodiment 3

[0018] Example 3: Connect compressed air with a pressure of 3.8kg into the compressed air channels 2 and 6, set the temperature to 110°C and the density to 1.41g / cm 3 1. The emulsification matrix with a flow rate of 3t / h is connected to the emulsification matrix channel 3 and atomized through the three-flow nozzle. During the atomization process, the emulsified matrix is filled with gas while cooling to achieve the effect of sensitization. The resulting explosive density is 1.05g / cm 3 , the temperature is 40°C, and the detonation velocity of the explosive is 4500m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com