Manufacture of laser-burnt multilayered circuit board

A technology of a multilayer circuit board and a manufacturing method, applied in the direction of multilayer circuit manufacturing, etc., can solve problems such as deviation from the characteristics and efficacy of the invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

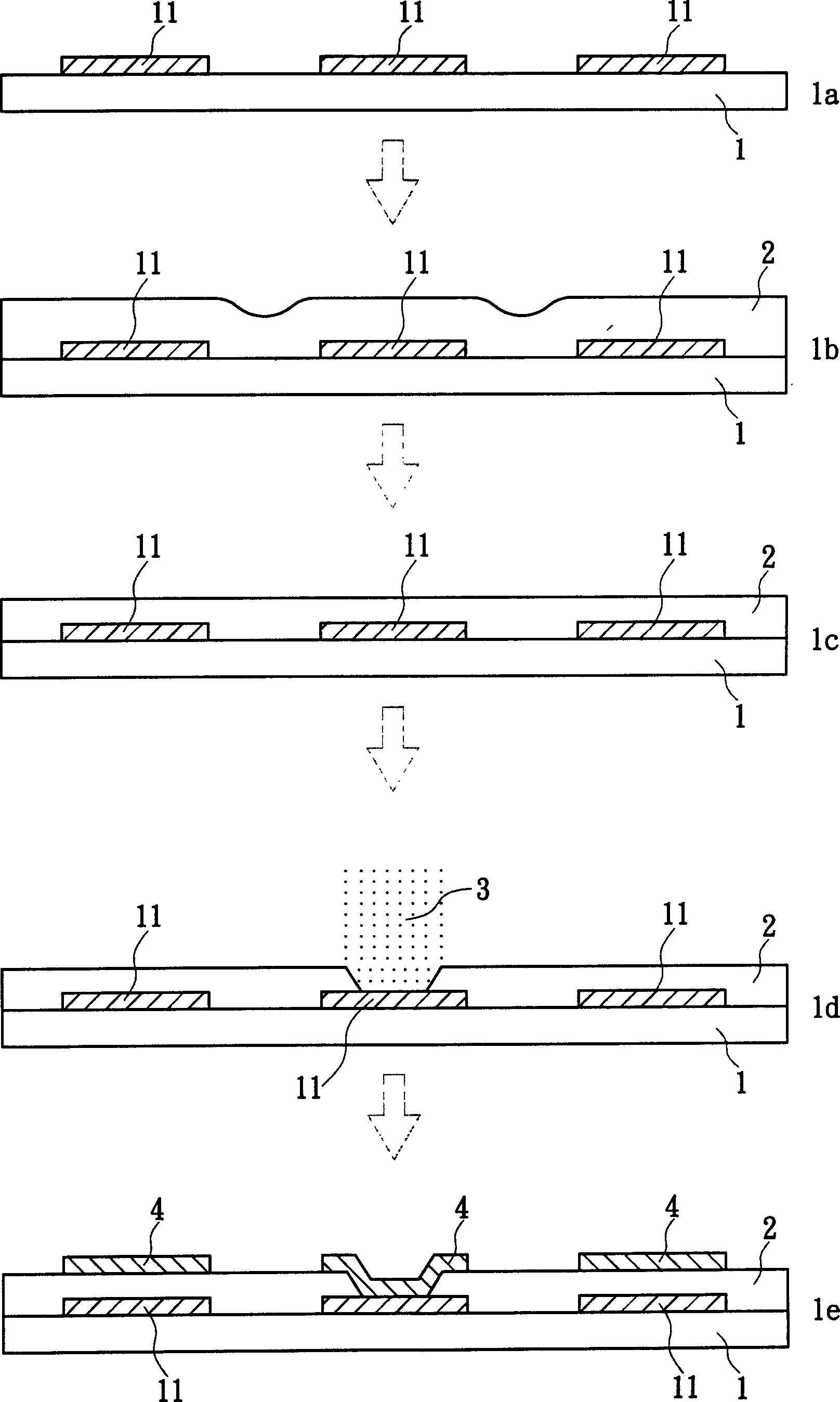

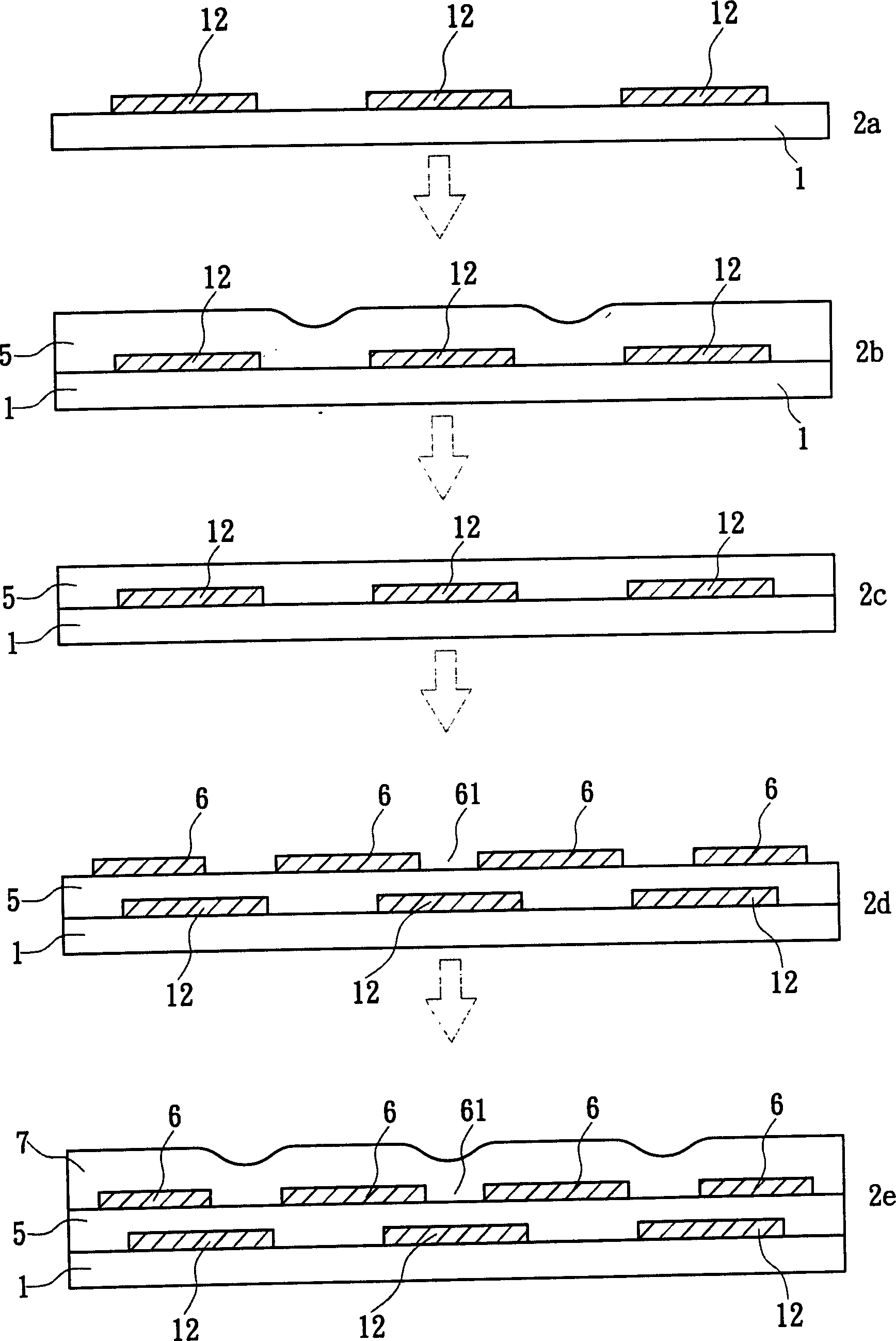

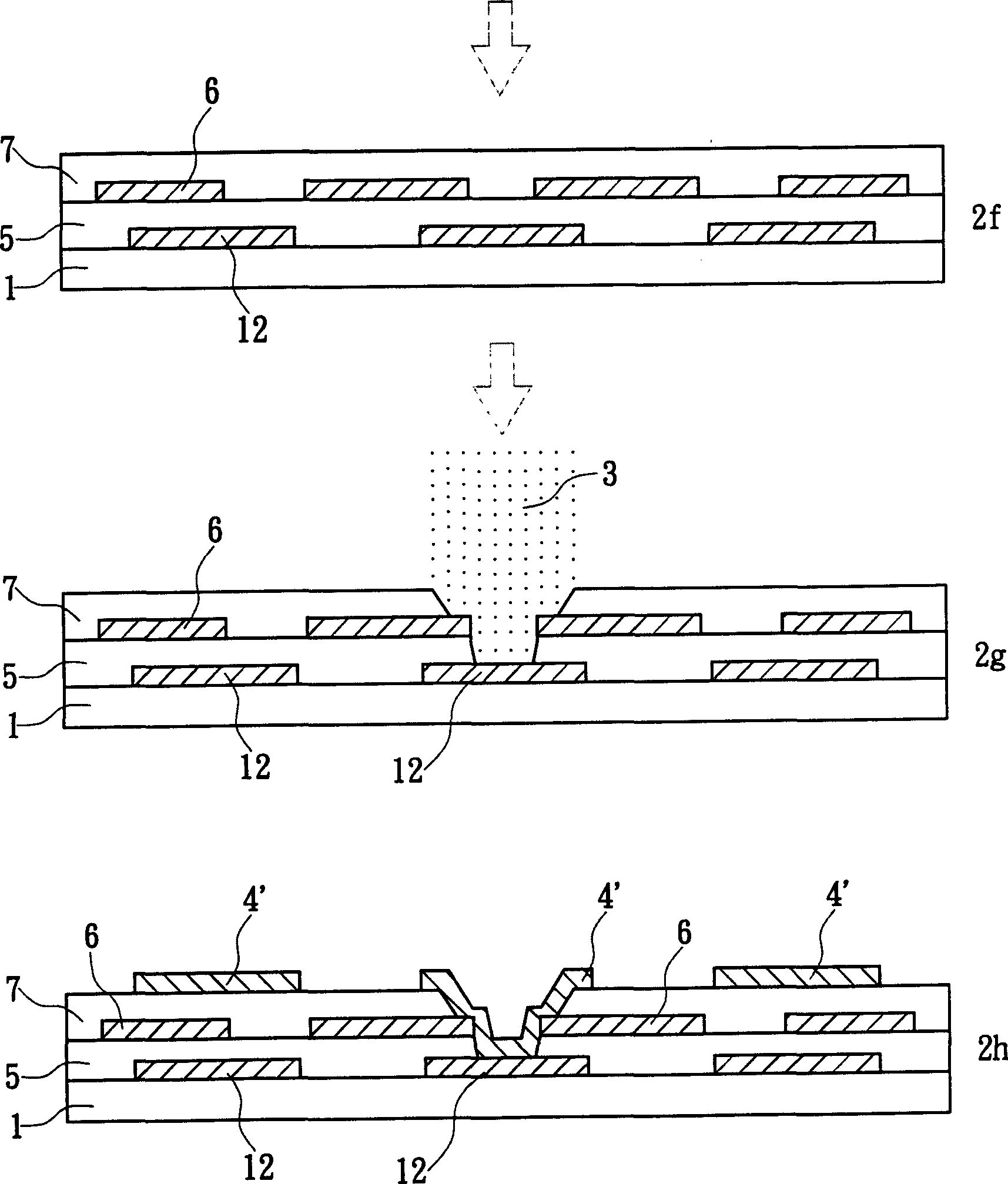

[0025] See first figure 1 The present invention is by each manufacture step as described below, hereby it is described as follows:

[0026] (1a), the dielectric material 2 of dry film or printing ink is coated on a substrate 1 with copper surface circuit 11:

[0027] (1b), then bake the dielectric material 2, so that the dielectric material 2 can be polymerized and molded on the substrate 1;

[0028] (1c), and then use the abrasive belt or brushing method to level the dielectric material 2, so that the dielectric material 2 has better flatness, so that the surface of the final product will not have unevenness, and the surface is clean and rough surface effect, to improve the bonding of the upper copper surface circuit 4;

[0029] (1d), then burn and melt the connection point on the dielectric material 2 to form a hole with the laser beam 3, so that the copper surface circuit 11 on the substrate is exposed;

[0030] (1e), finally metallize and electroplate on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com