New technological method-1 for detecting shear wave speed in geotechnical static and dynamic triaxial instrument

A dynamic three-axis, shear wave technology, applied in the direction of soil material testing, instruments, measuring devices, etc., can solve the problems of difficult matching, small sensor radiation energy, low electromechanical coupling coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

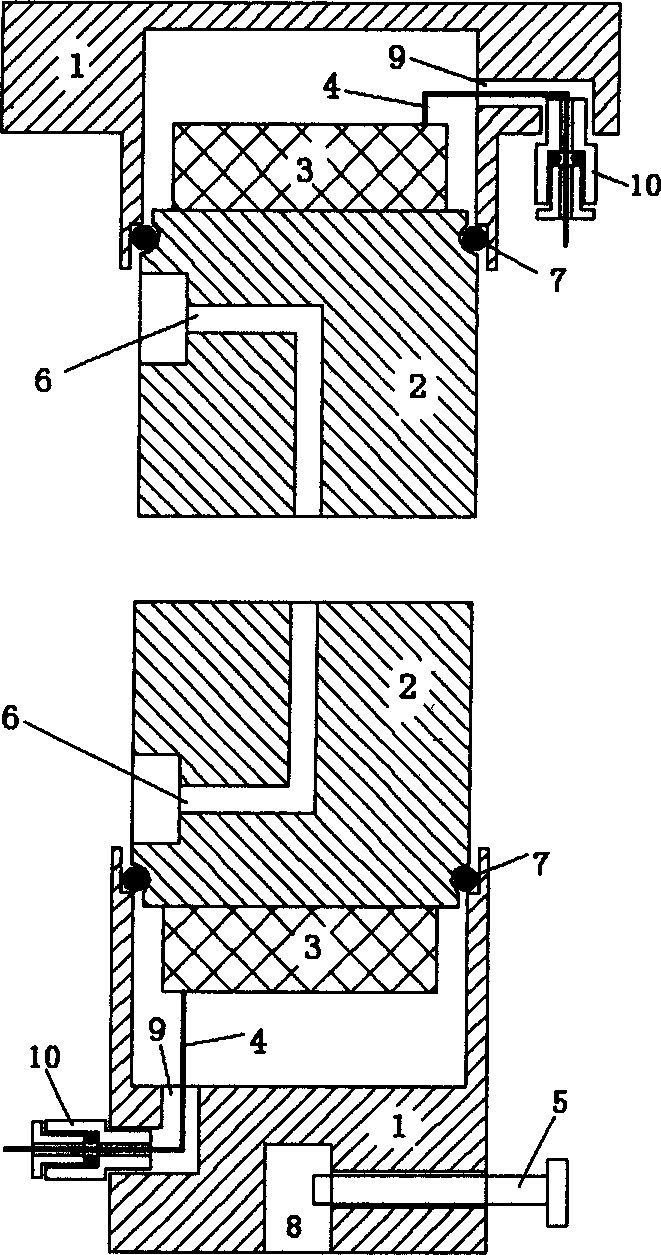

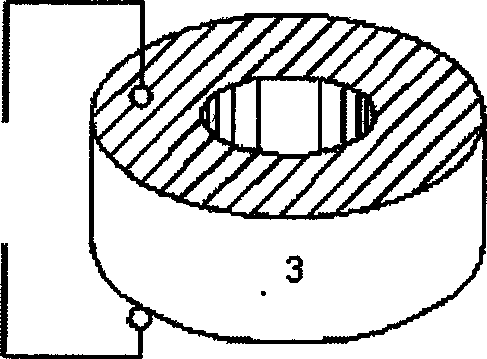

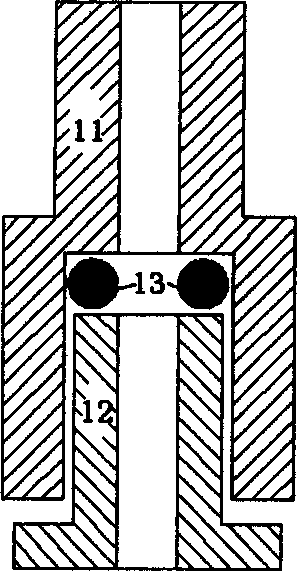

[0009] Refer to attached Figure 1~4 . The upper and lower shells are made of stainless steel or other metals, and the external dimensions are φ40mm~φ80mm×30~80mm (according to the size of the supporting triaxial instrument). Radiator is a cylinder of lightweight hard metal, the specific size matches the shell, and there is a φ3mm drainage path in the center. The vibrator is a circular ring of φ10mm~φ30mm×φ20mm~φ75mm×5mm~30mm (depending on the required vibration frequency). When assembling, first connect the upper and lower electrodes of the vibrator with the lead-out cable (4), then lead the cable out of the shell through the cable lead-out hole, and fix the cable on the shell through the cable lead-out joint. Put O-rings in the grooves of the radiator and the end of the housing. Pressurization presses the bonded radiator and vibrator into the housing.

[0010] The size of the radiator used is φ39.1mm, the height of the upper sensor (radiator and vibrator) is 50mm, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com