Digital control wire peeler

A technology of wire stripping machine and wire entry, which is applied in the direction of line/collector parts, electrical components, circuits, etc., and can solve problems such as time-consuming, messy, and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

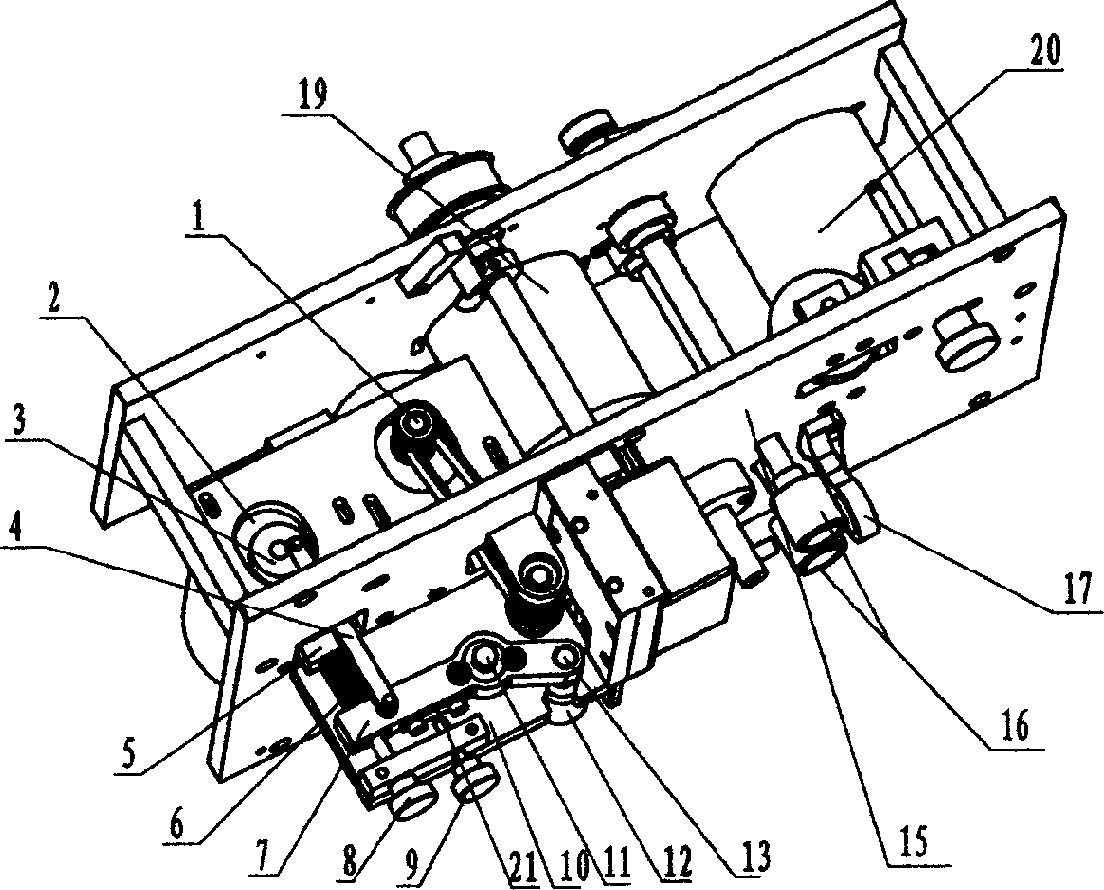

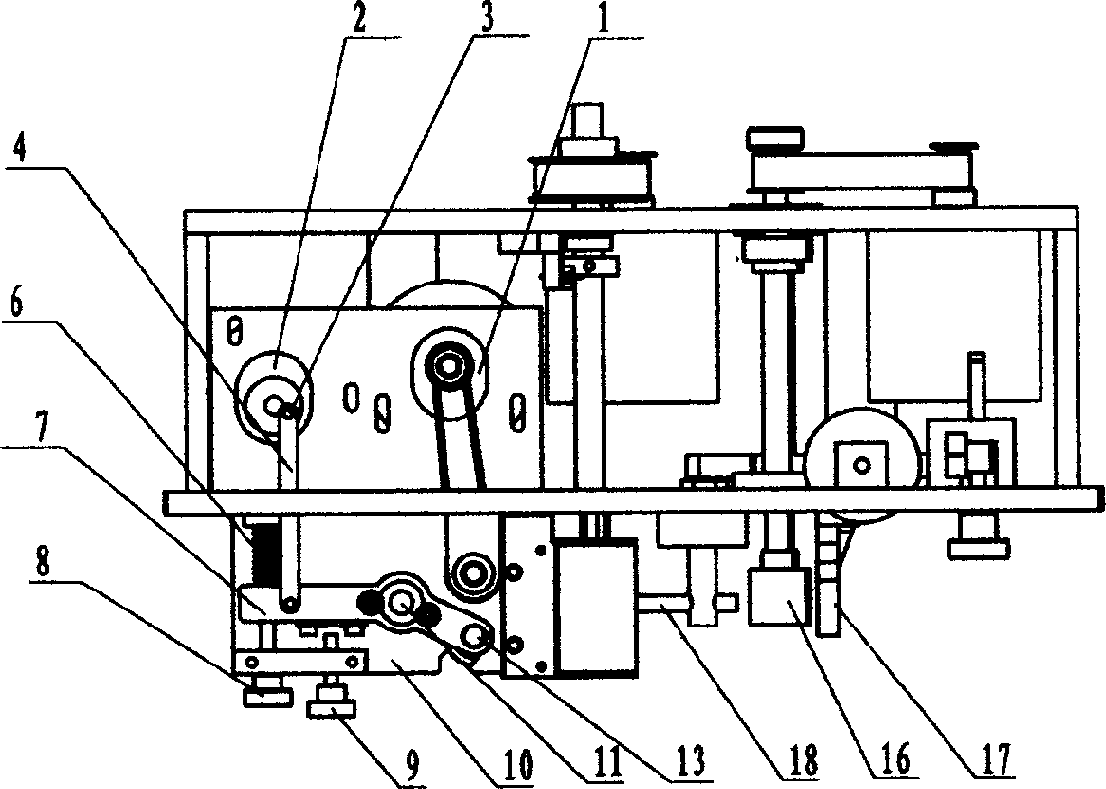

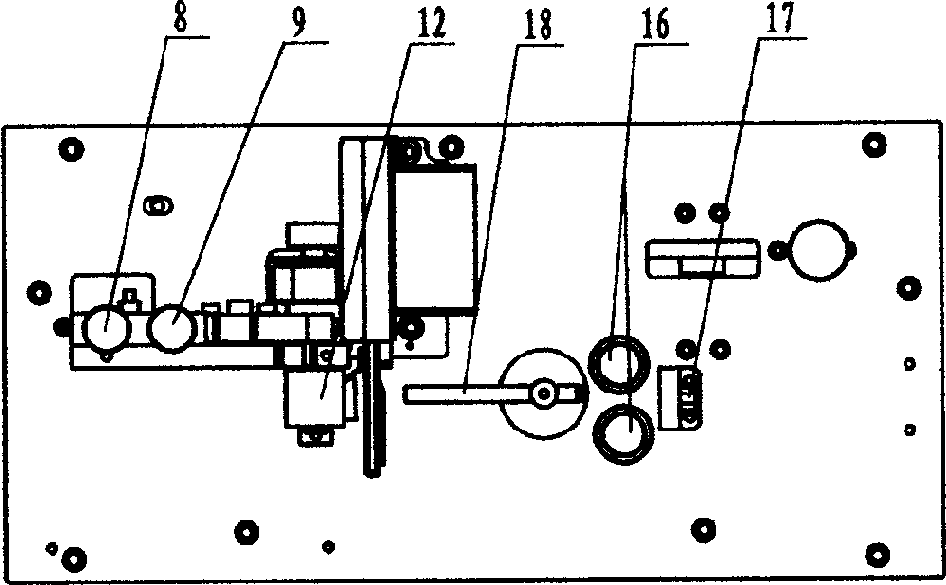

[0011] The accompanying drawings have shown the structure of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be described in detail below in conjunction with the accompanying drawings. The numerically controlled wire stripping machine has numerically controlled components and mechanical components. The numerically controlled components include a power supply, a computer single-chip microcomputer, a stepper motor constant current chopper driver and a numerically controlled display on the control panel of the box body, and is also provided with a matching Keyboard, the power supply, computer single-chip microcomputer, numerical control display and keyboard are not shown in the figure, the mechanical parts include a wire inlet mechanism, a cutting and stripping mechanism and a wire outlet mechanism, and the wire inlet mechanism, cutting and stripping mechanism and wire outlet mechanism are respectively Connect with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com