Method and device for heating sealed cooked food in dish by microwave

A tray and microwave technology, applied in microwave heating, electric heating devices, food heating containers, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

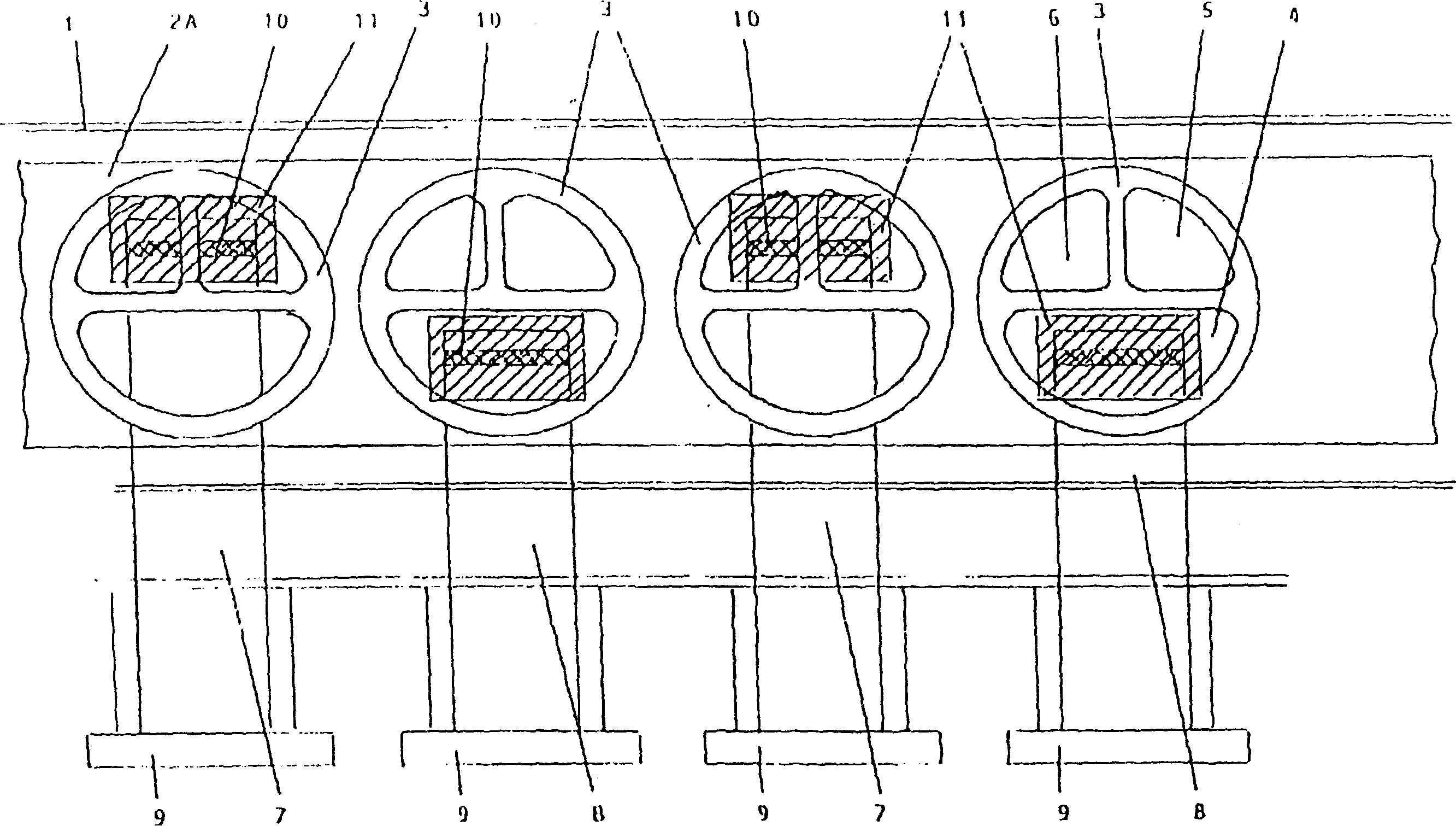

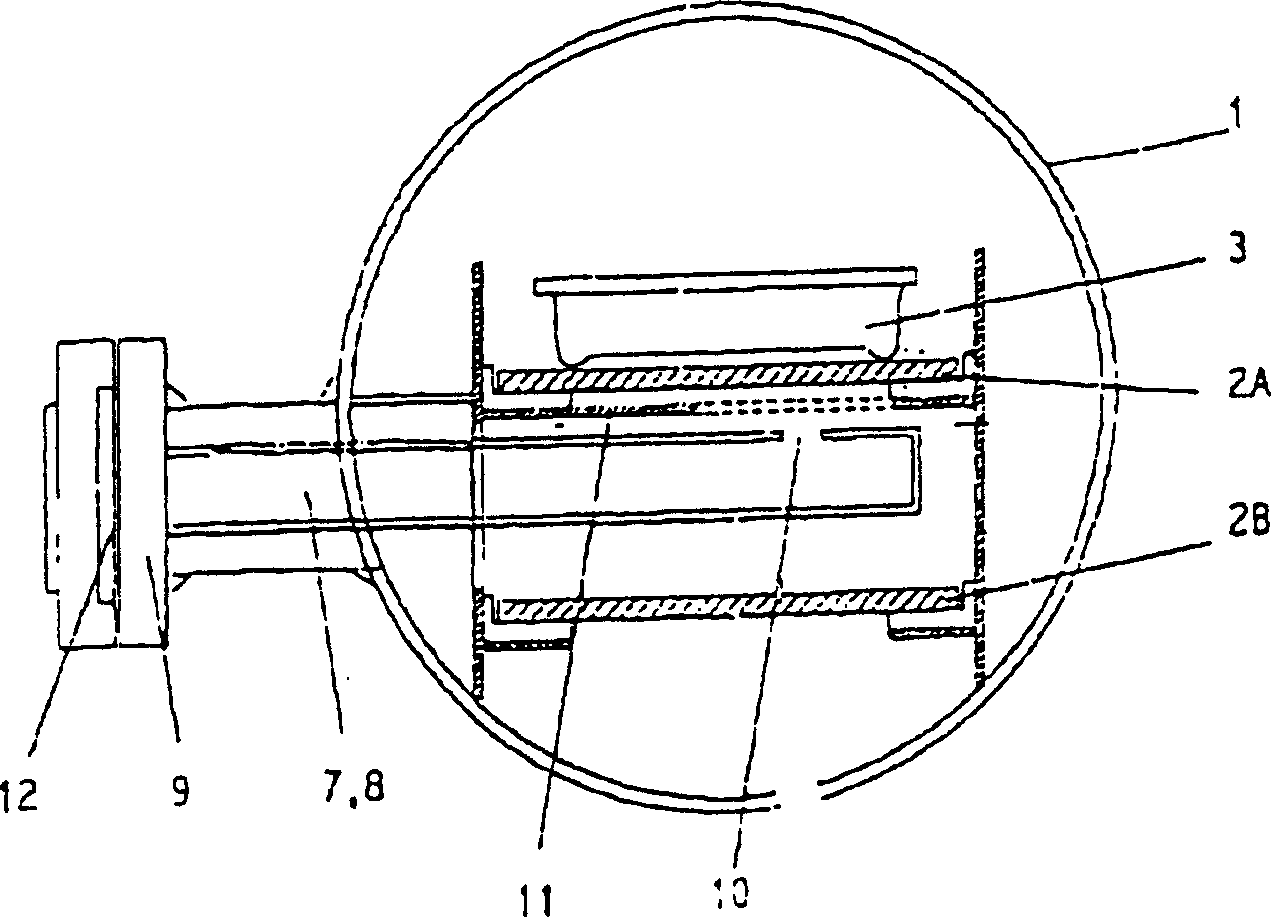

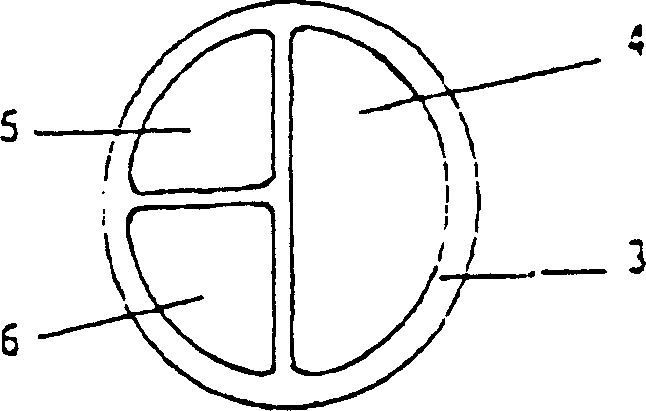

[0030] Inside the tubular autoclave 1 is a conveyor belt 2 with an upper run 2A and a lower run 2B. Tray 3 is placed on the upper return section 2A, and tray 3 has a portion of rice to be heated in grids 4, 5, 6 placed on tray 3. Like this, can put meat and seasoning in grid 4, put potato or pasta in grid 5, put vegetables in grid 6.

[0031] The waveguides 7 , 8 protrude laterally into the autoclave 1 , to whose flange 9 a microwave generator (not shown) is connected. The waveguide 7 is longer than the waveguide 8 . Both waveguides have openings 10 at their ends, from which microwaves are output. Here, the openings 10 in the long waveguide 7 are used to heat the tray grid 4 where the meat and spices are placed, while the openings 10 in the short waveguide 8 are used to heat the grids 5 and 6 in the tray 3 where the pasta, potatoes and vegetables are placed .

[0032] The opening 10 is arranged upwards immediately below the portion tray 3 with the portion to be heated. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com