Camera device and camera lens

A technology of camera lens and camera device, applied in image communication, exposure control, instruments, etc., can solve the problems of reduced peripheral opening efficiency, large back focal length, trouble, etc., and achieve the effect of miniaturization and thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

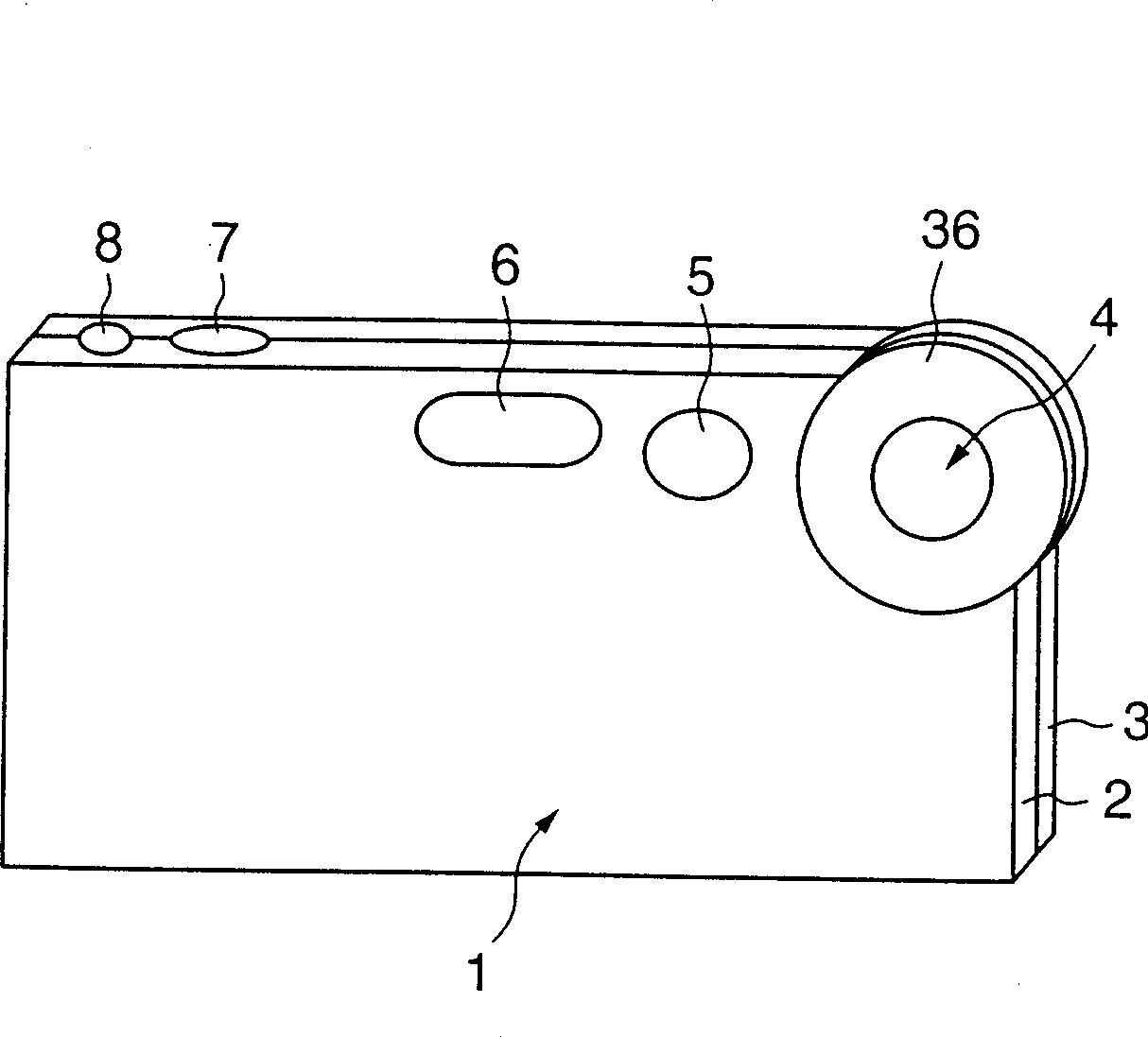

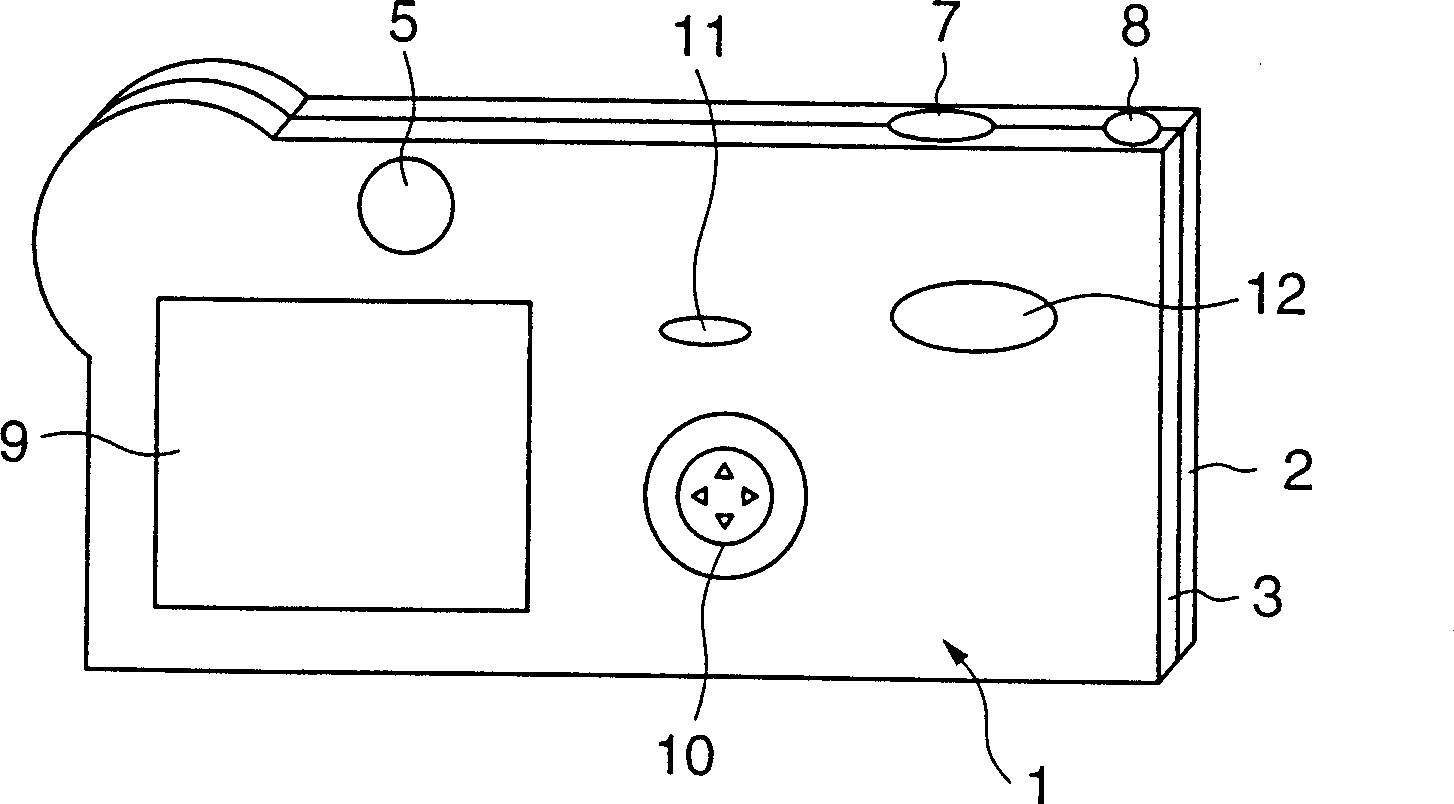

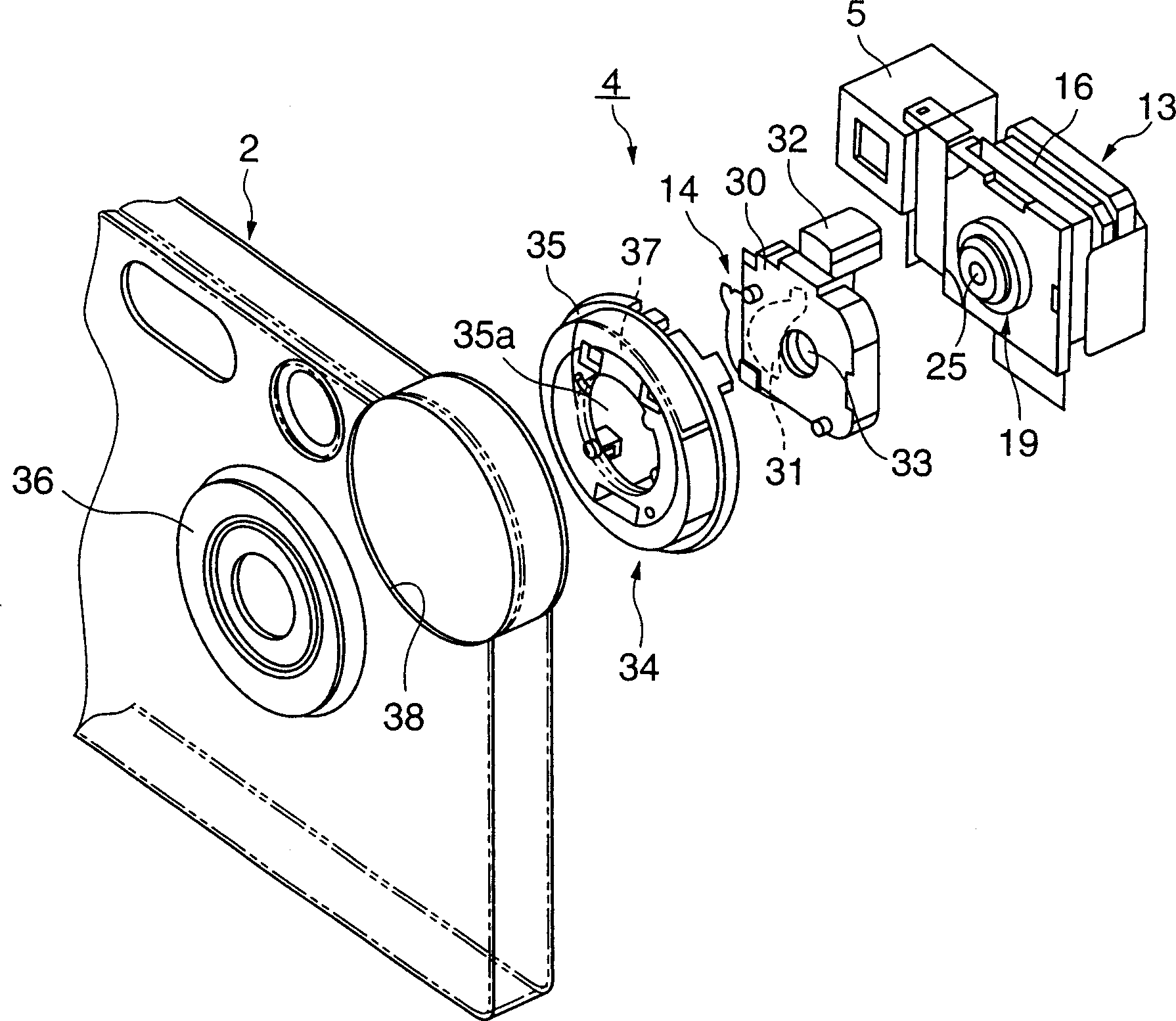

[0038] Below, refer to Figure 1 to Figure 5 One embodiment of an imaging device in which the present invention is applied to a video card will be described.

[0039] figure 1 Shown is a perspective view of the cassette camera of the present invention from the front side, figure 2 Shown is a perspective view of the cassette camera of the present invention from the rear side, image 3 Shown is figure 1 An exploded oblique view of the main parts, Figure 4 yes image 3 side view of Figure 5 Shown is image 3 An enlarged oblique view of the camera unit.

[0040] Such as figure 1 with figure 2 As shown, the card camera has a camera 1 main body 1 . The camera body 1 is composed of a front case 2 and a rear case 3, and either of the front case 2 and the rear case 3 is formed of a thin plate made of a highly rigid metal such as stainless steel.

[0041] This situation, such as figure 1 As shown, a photographing device 4 is provided at the upper right corner of the front ...

Embodiment 2

[0055] Next, refer to the following Figure 6 to Figure 9 The photographic optical system related to the present invention will be described.

[0056] The imaging lens of the present invention is characterized in that the back focus is set relatively short by arranging an infrared light absorption filter on the subject side of the imaging lens in an imaging optical system using an imaging element such as a CCD. .

[0057] Table 1 shows the existing example of disposing the infrared light absorption filter between the imaging lens and the imaging element, and the design of disposing the infrared light absorption filter of the present invention on the side closest to the subject of the imaging lens. Comparison of the full length (TL) of an example. The total length TL on the optical axis of the conventional example is -16.59 mm, and the total length TL of one embodiment is 15.76 mm. Their difference of 0.83mm is the effect of the present invention, and it can be proved that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com