High-efficiency dc motor improved structure

A DC motor, improved structure technology, applied in the direction of DC commutator, collector, electrical components, etc., can solve the problems affecting the range of DC motor use, commutator and brush wear, limited winding range, etc., to achieve Good heat dissipation, low starting current and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

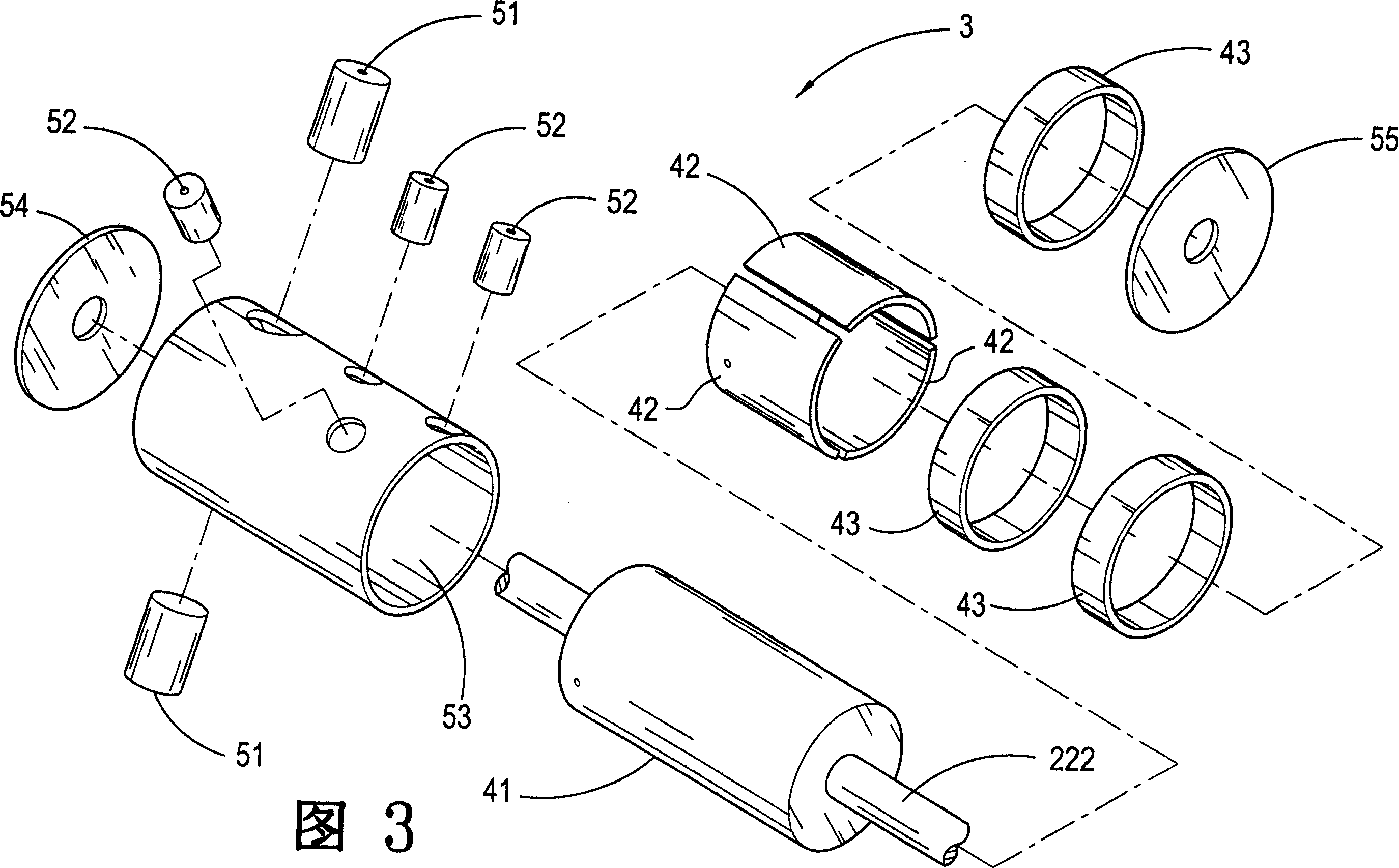

[0028] The invention is an improved structure of a high-efficiency DC motor, which is composed of an inner magnetic motor and a control module.

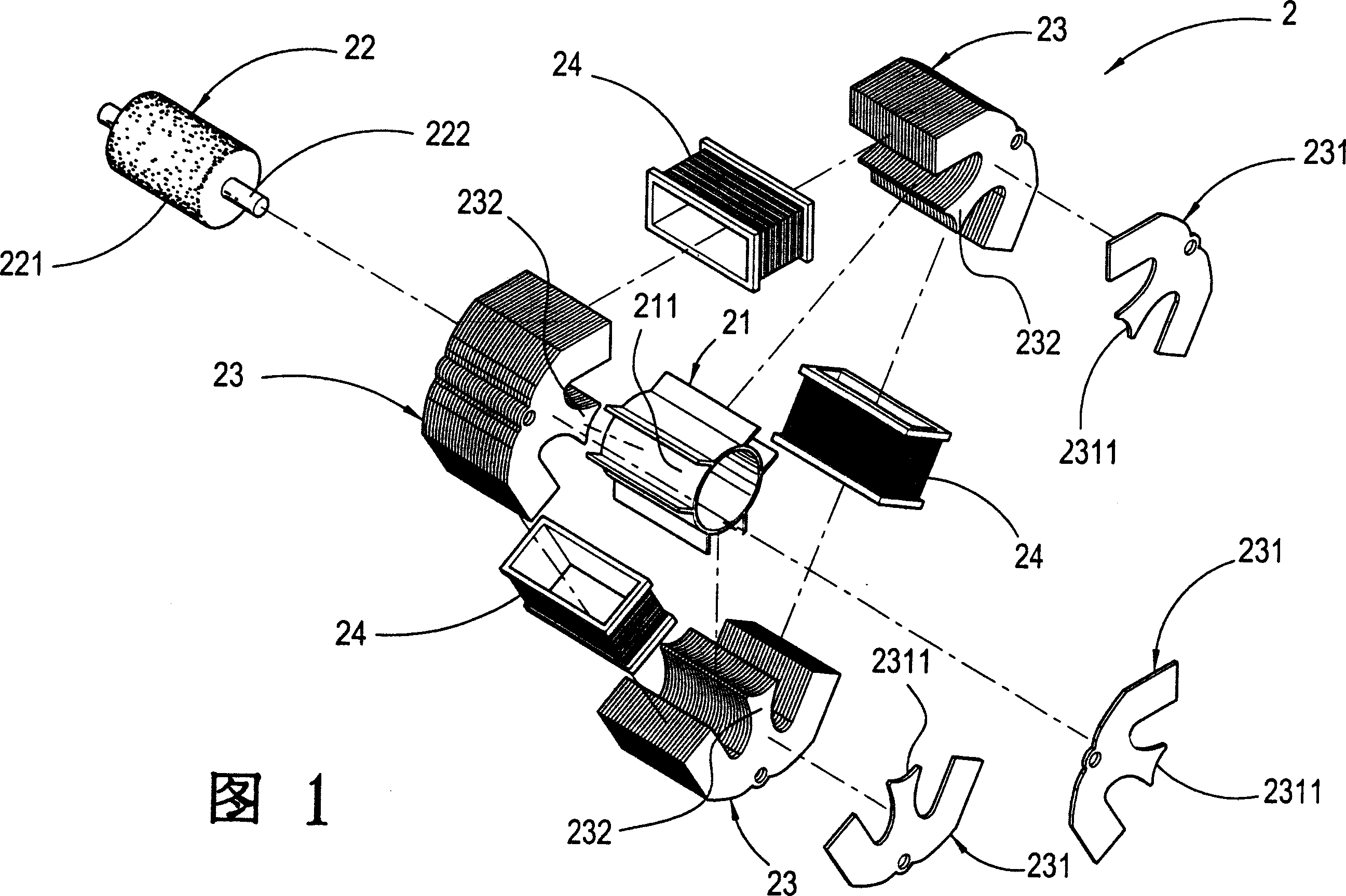

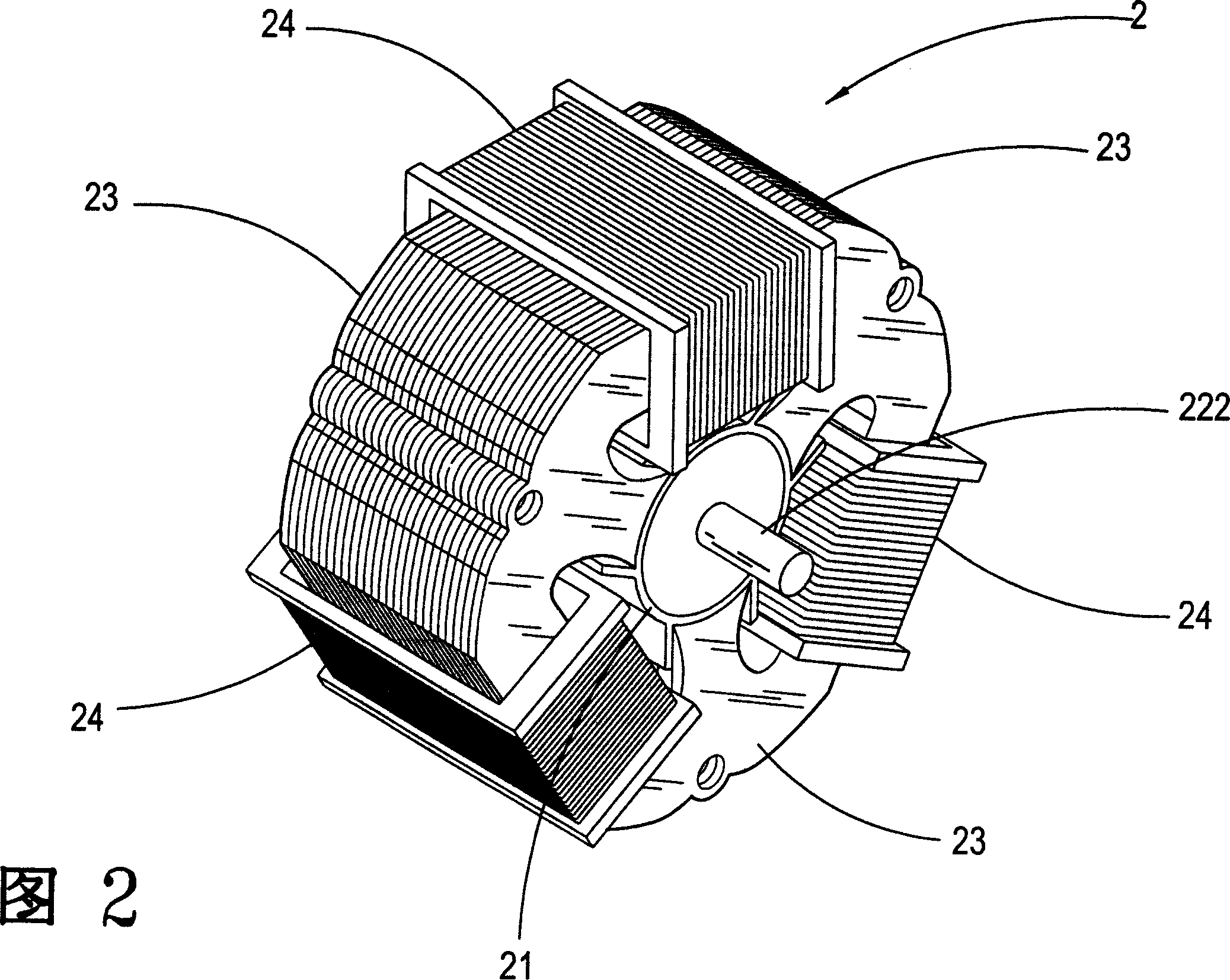

[0029] Please refer to Fig. 1 and Fig. 2, which are exploded schematic diagrams and physical schematic diagrams of the internal magnetic motor. It can be seen from the figures that the internal magnetic motor 2 mainly includes:

[0030] A non-metallic magnet seat 21, which is provided with three standard grooves 211 in equal parts outside the non-metallic magnet seat 21;

[0031] An axis 22, the axis 22 is composed of a magnet 221 and a power center shaft 222, the power center shaft 222 runs through the central part of the magnet 221, so that the center shaft 222 protrudes from the two ends of the magnet 221, and The central axis 222 will extend to the control module;

[0032] Three silicon steel sheet groups 23 are formed by stacking several silicon steel sheets 231. The central part of the silicon steel sheet 231 has a protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com