Field emission display device

A display element and field emission technology, which is applied in the direction of electrical components, image/graphic display tubes, semiconductor devices, etc., can solve the problem of high power consumption of components, achieve the effects of reducing emission voltage, facilitating tip discharge, and improving emission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

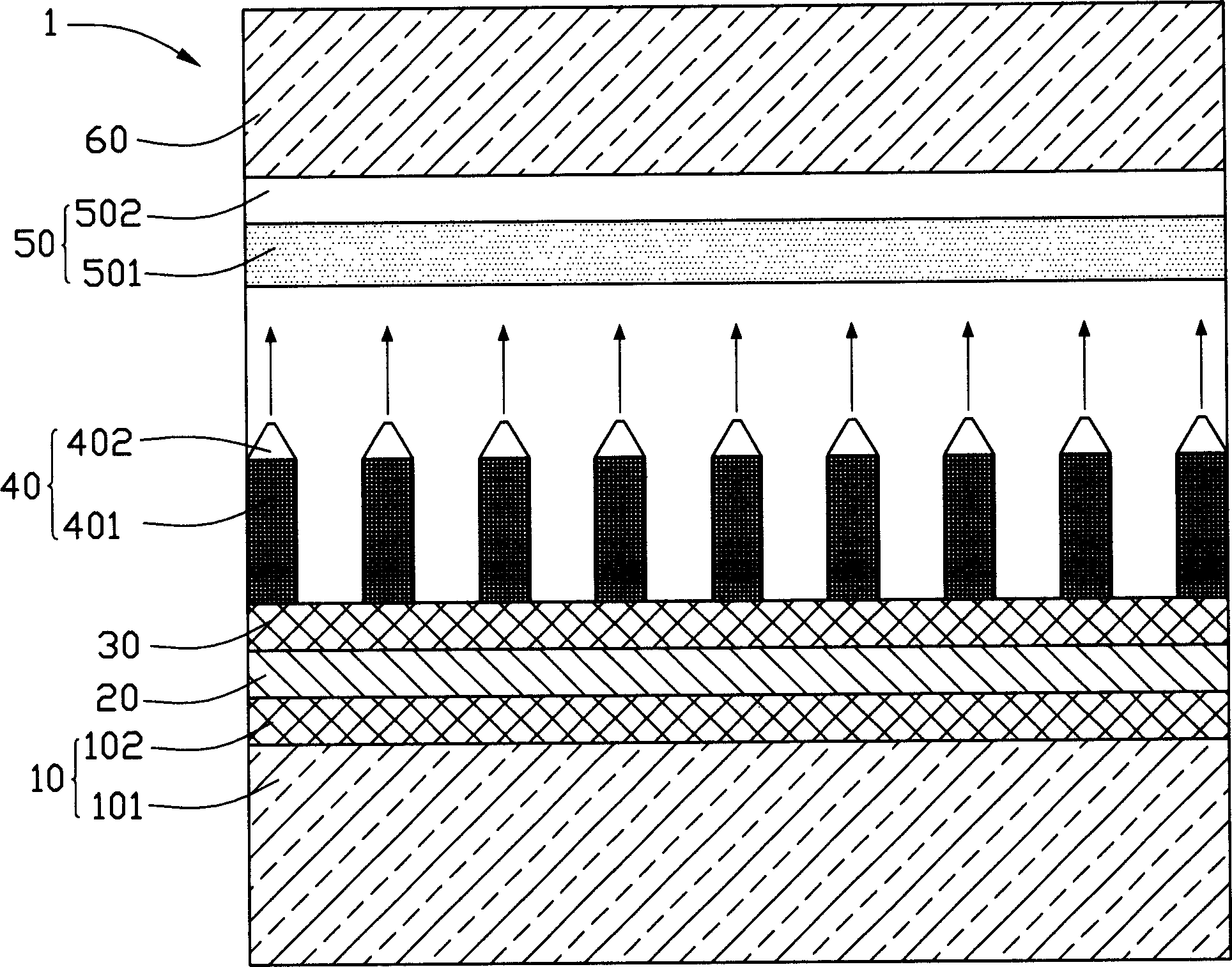

[0015] see figure 1 The field emission display element 1 of the present invention comprises a first substrate 10, a cathode plate 20 made of conductive material and formed on the first substrate 10, a resistor buffer layer 30 connected to the cathode plate 20, formed on the resistor A plurality of electron emission units 40 on the buffer layer 30 , an anode plate 50 spaced apart from the plurality of electron emission units 40 , and a second substrate 60 .

[0016] The first substrate 10 includes a glass substrate 101 and a silicon thin film layer 102, the silicon thin film layer 102 is formed on the glass substrate 101, the silicon thin film layer 102 has bonding properties, which can provide effective bonding between the cathode plate 20 and the glass substrate 101. connect.

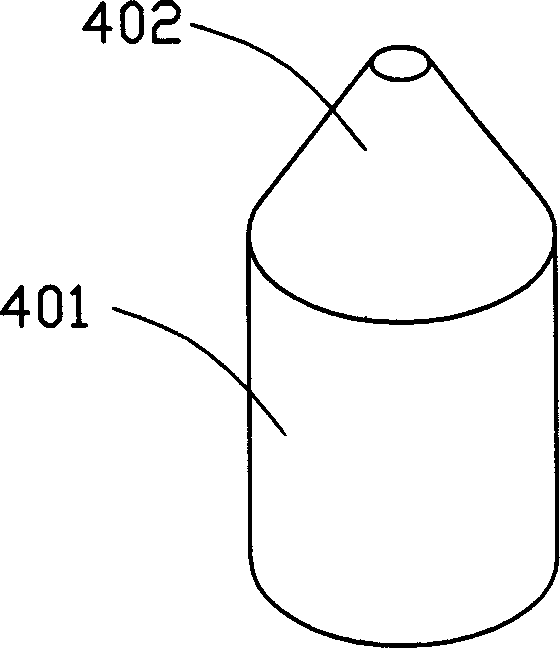

[0017] Please refer to figure 2 , each electron emission unit 40 is composed of a columnar first part 401 in contact with the resistance buffer layer 30 and a conical second part 402 away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com