Fully automatic supersonic cleaner withs several functional sites

An ultrasonic cleaning, fully automatic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of low cavitation strength, corrosion, inconsistent cleaning effect, etc., to reduce pollution and improve. The effect of ultrasonic cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

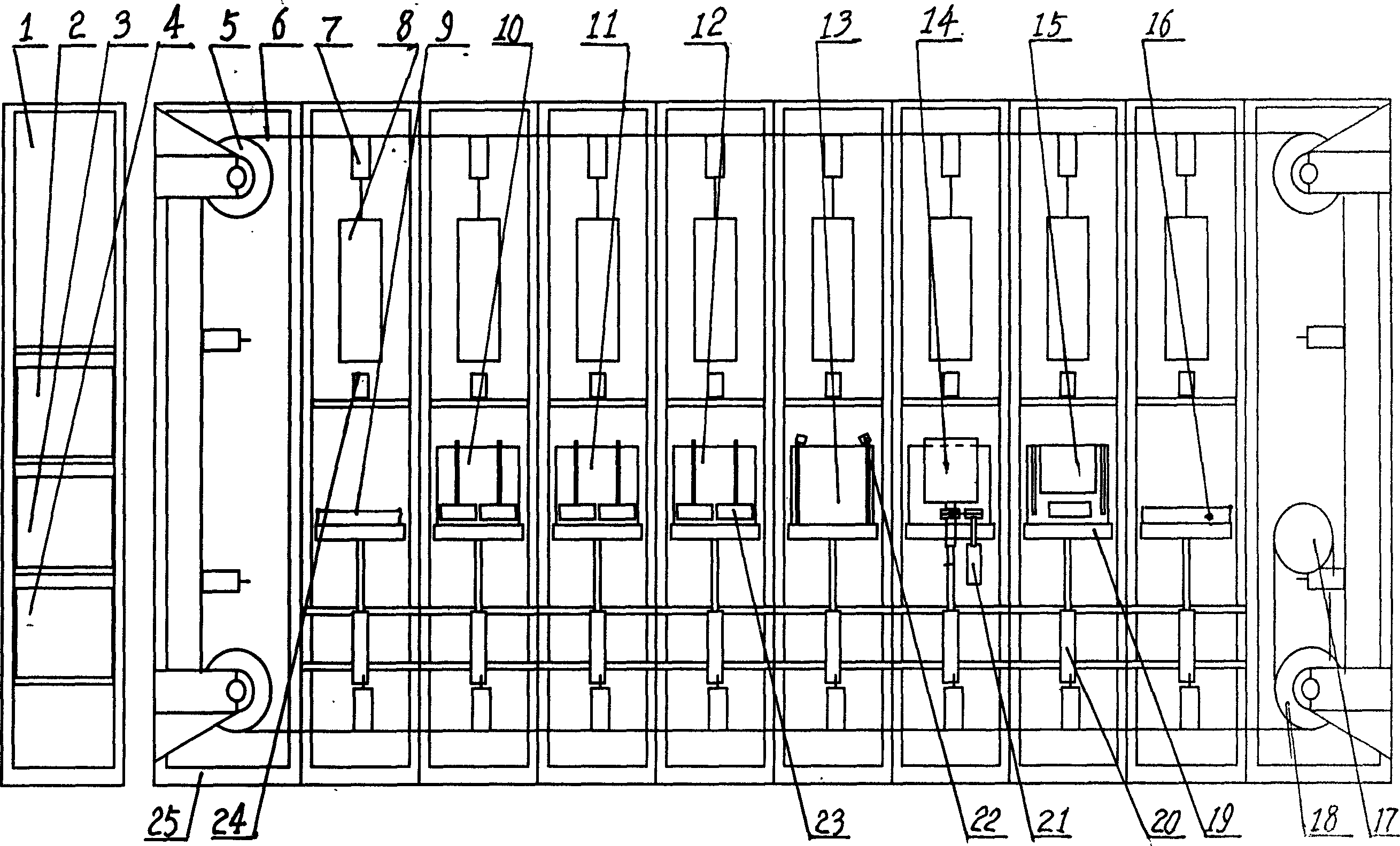

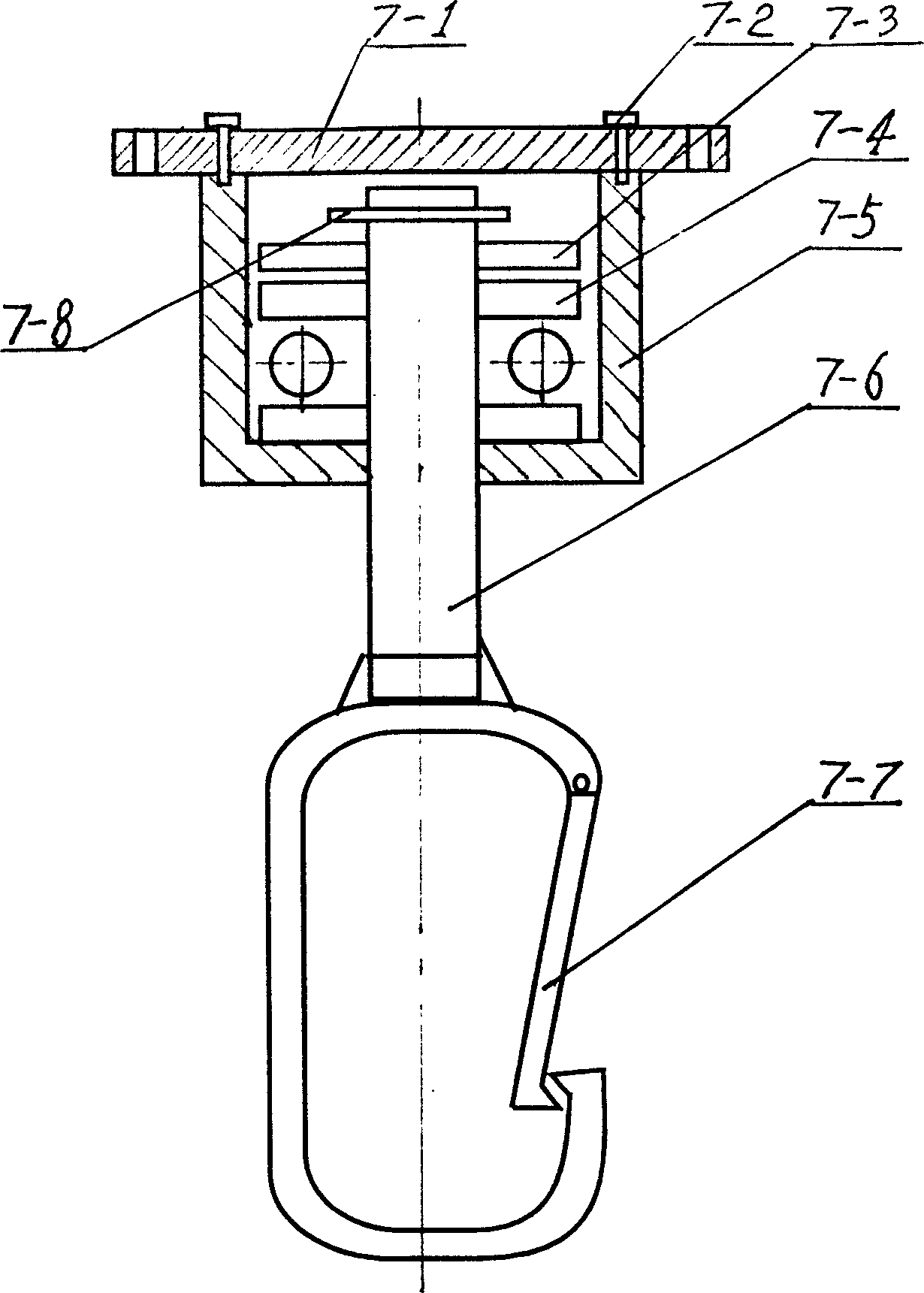

[0025] exist figure 1 Among them, the multi-station automatic ultrasonic cleaning device implemented in this implementation consists of a control cabinet 1, a high-frequency ultrasonic generator 2, an intermediate-frequency ultrasonic generator 3, a low-frequency ultrasonic generator 4, a reversing sprocket 5, a chain 6, and a rotating hanger 7 , Cleaning workpiece loading column 8, workpiece loading table 9, low-frequency ultrasonic cleaning tank 10, medium-frequency ultrasonic cleaning tank 11, high-frequency ultrasonic cleaning tank 12, shower cleaning tank 13, frequency conversion dehydrator 14, hot air generator 15, workpiece unloading table 16. Electric motor 17, driving sprocket 18, bracket 19, lifting cylinder 20, frequency conversion motor 21, shower nozzle 22, ultrasonic vibrating body 23, photoelectric sensor 24, and bracket 25 are connected to form, wherein lifting cylinder 20 is connected to bracket 19 As a lifting mechanism, the motor 17 is an embodiment of the p...

Embodiment 2

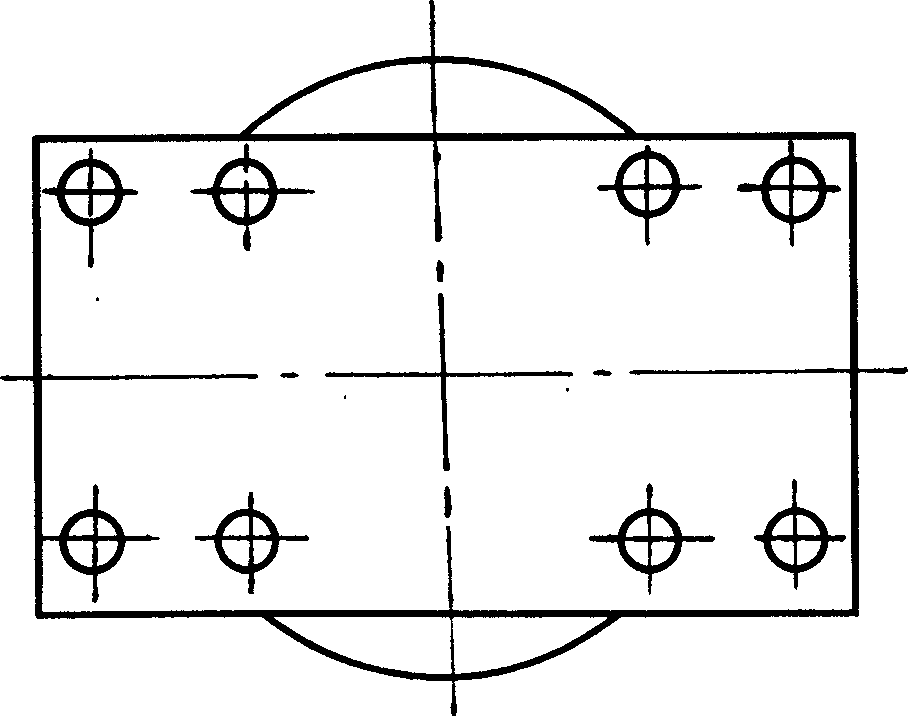

[0034] In this embodiment, the ultrasonic transducer array of the ultrasonic vibrating body 23 installed in the low-frequency ultrasonic cleaning tank 10, the intermediate-frequency ultrasonic cleaning tank 11, and the high-frequency ultrasonic cleaning tank 12 is composed of six ultrasonic transducers 23-3. . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0036] In this embodiment, the ultrasonic transducer array of the ultrasonic vibrating body 23 installed in the low-frequency ultrasonic cleaning tank 10, the intermediate-frequency ultrasonic cleaning tank 11, and the high-frequency ultrasonic cleaning tank 12 is composed of 40 ultrasonic transducers 23-3. . Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0037] Working process of the present invention is as follows:

[0038] The motor 17 drives the chain 6 to rotate, the control cabinet 1 controls the lifting cylinder 20 to work, so that the loading table 9 rises, and the operator can put the workpiece into the cleaning workpiece loading column 8, the low-frequency ultrasonic cleaning tank 10, the medium-frequency ultrasonic cleaning tank 11, and the high-frequency ultrasonic cleaning tank 11. The high-frequency ultrasonic cleaning tank 12 is respectively controlled by the control cabinet 1 to work with the lift cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com